Silicone breast forms having phase-change energy storage function and manufacturing method thereof

A technology of phase change energy storage and production method, applied in the field of silicone breast implants and its production, can solve the problems of human body harm, feeling stuffy, single breast implants, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

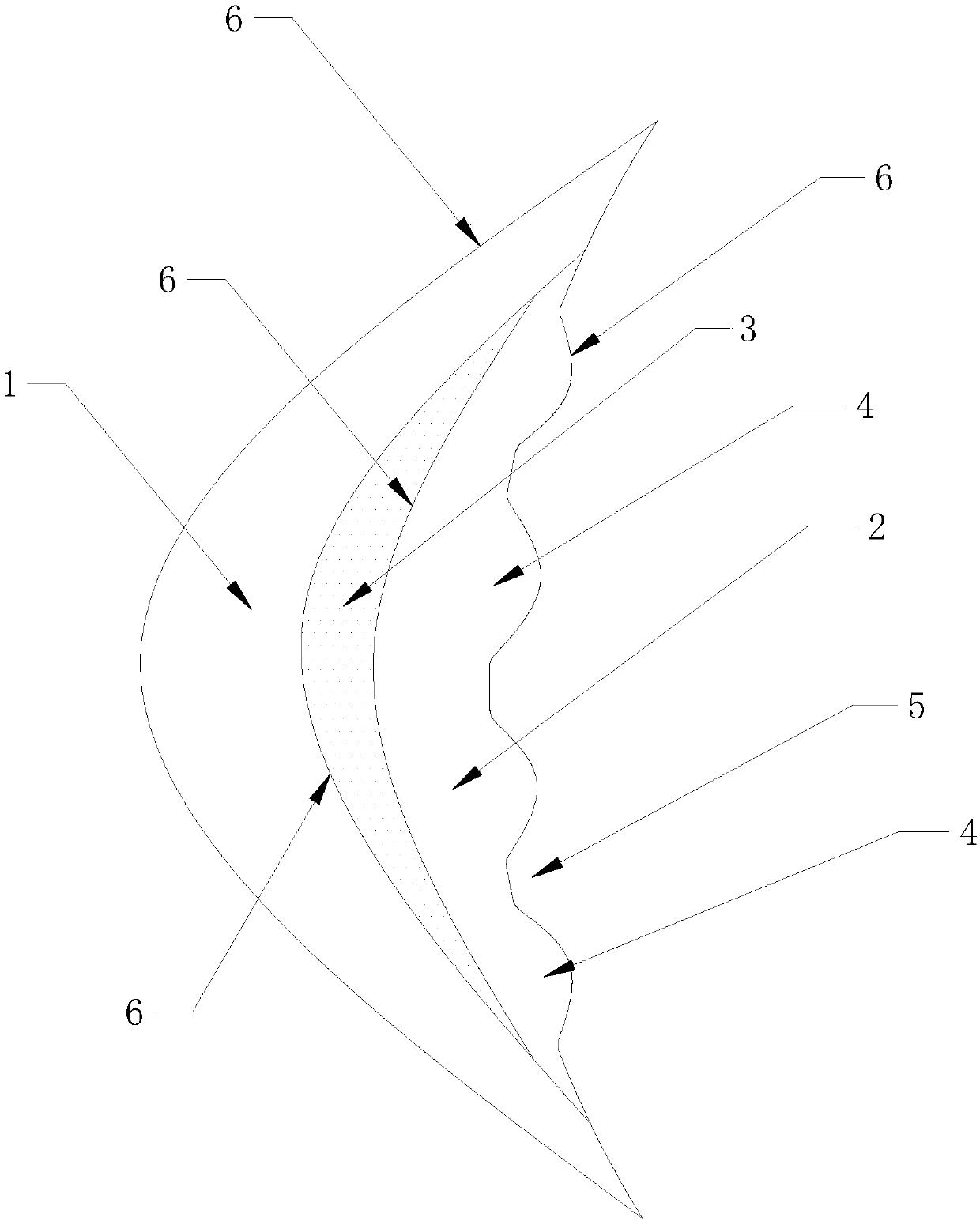

[0032] See attached figure 1 , a silicone prosthesis with a phase-change energy storage function in this embodiment, including a phase-change layer 3 in the middle and a first silicone layer 1 and a second silicone layer 2 on both sides of the phase-change layer 3 . When worn, the first silica gel layer 1 is away from the human body, and the second silica gel layer 2 is close to the human body.

[0033] The phase change layer 3 is filled with a phase change material. The phase change material in this embodiment is a phase change energy storage microsphere. The phase change temperature of the phase change energy storage microsphere is 32-37° C., and 35° C. is selected in this embodiment. The phase change temperature of the selected phase change energy storage microspheres is compatible with the body temperature. When the temperature of the hu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com