Sewage separating technology

A sewage and process technology, applied in filtration separation, separation methods, water/sewage treatment, etc., can solve problems such as troublesome and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

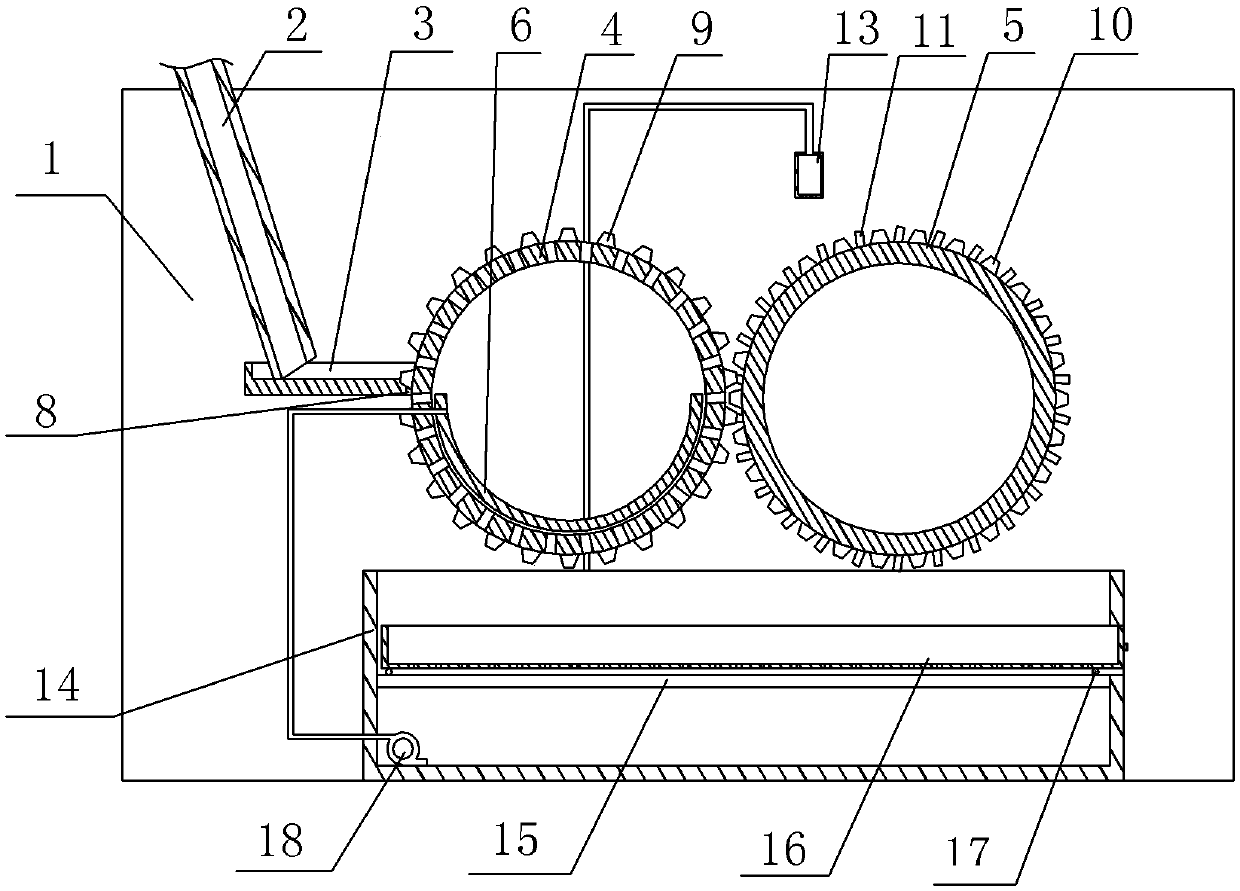

[0019] Further detailed explanation through specific implementation mode below:

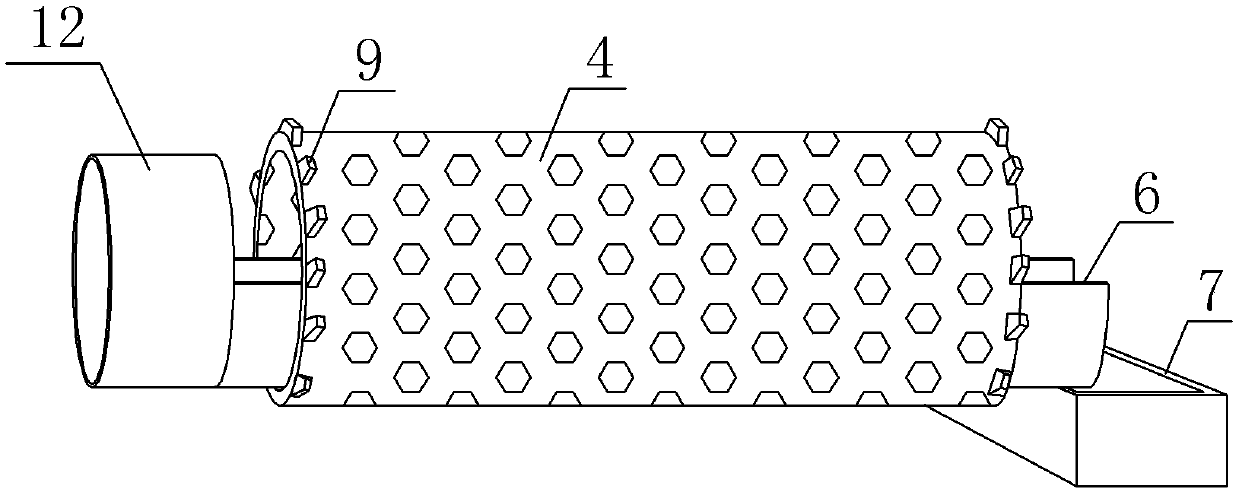

[0020] The reference signs in the drawings of the description include: cavity 1, feed pipe 2, receiving tank 3, filter cartridge 4, drum 5, water holding pipe 6, water holding tank 7, sealing strip 8, No. 1 gear 9, No. 2 gear 10. Scraper 11, outlet pipe 12, effluent tank 13, collection box 14, slide rail 15, collection box 16, pulley 17, No. 2 water pump 18.

[0021] A kind of sewage separation process specifically comprises the steps:

[0022] Step 1: Prepare a figure 1 The shown sewage treatment device includes a chamber body 1, and the chamber body 1 is provided with a feed pipe 2, a receiving tank 3, a filter cartridge 4, a drum 5, a water holding pipe 6 and a water holding tank 7. Feeding pipe 2 is obliquely fixed on the frame, receiving groove 3 is horizontally fixed on the frame, and the lower end of feeding pipe 2 is in contact with receiving groove 3 . The filter cartridge 4 is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com