Slagging backflow transition structure for offshore drill tool

A transitional structure and backflow technology, which is applied in construction and other directions, can solve problems such as differences in absorption capacity, poor torsion resistance, and inconsistent resistance at the absorption port, and achieve the effects of preventing cracking, air leakage, and stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

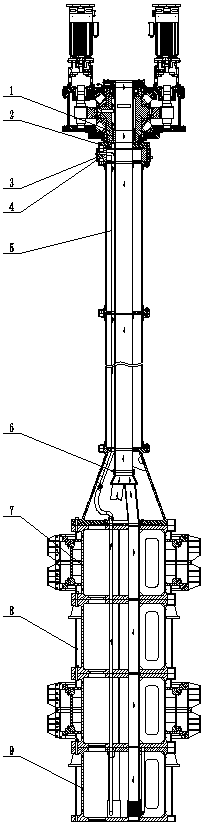

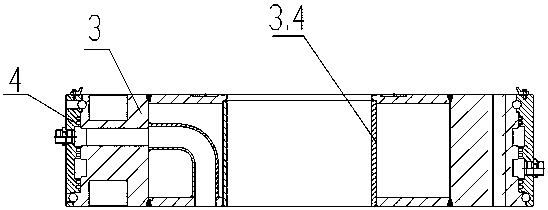

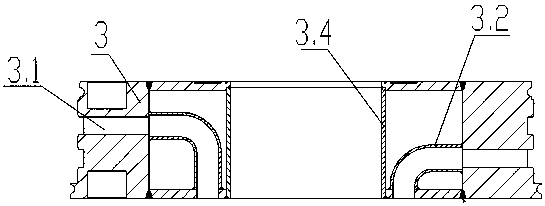

[0031] see Figure 1~10 , the present invention relates to a slagging backflow transition structure for offshore drilling tools, the structure includes a transition joint 6, the transition joint 6 includes an upper small flange 6.2 and a lower large flange 6.3, connecting the cone The upper opening end of 6.1 is fixedly connected to the upper small flange 6.2, and the small opening end is fixedly connected to the lower large flange 6.3, and there are multiple connections between the upper small flange 6.2 and the lower large flange 6.3. Transition air pipe 6.4, the tops of multiple transition air pipes 6.4 correspond to and communicate with multiple in-line air pipes 5.7 in the drill pipe 5 located at the bottom of the drill pipe assembly, and the connecting cone 6.1 is provided with a slag discharge pipe three 6.5, slag discharge branch pipe 1 6.6 and slag discharge connecting taper pipe 6.7, the top of the slag discharge pipe 3 6.5 is connected to the upper small flange 6.2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com