Climate environment simulating design method for accelerated aging test of xenon lamp made from high molecular material

A polymer material, accelerated aging technology, used in analytical materials, weather resistance/light resistance/corrosion resistance, measurement devices, etc. Product service life difference and other issues, to achieve accurate prediction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Application method design simulation engineering plastics PC of the present invention is in the xenon arc accelerated aging test method of Hainan Qionghai environment, also can be used for the xenon arc accelerated aging test of general engineering plastics such as PS, PVC weather resistance in Qionghai, Hainan, concrete steps are as follows:

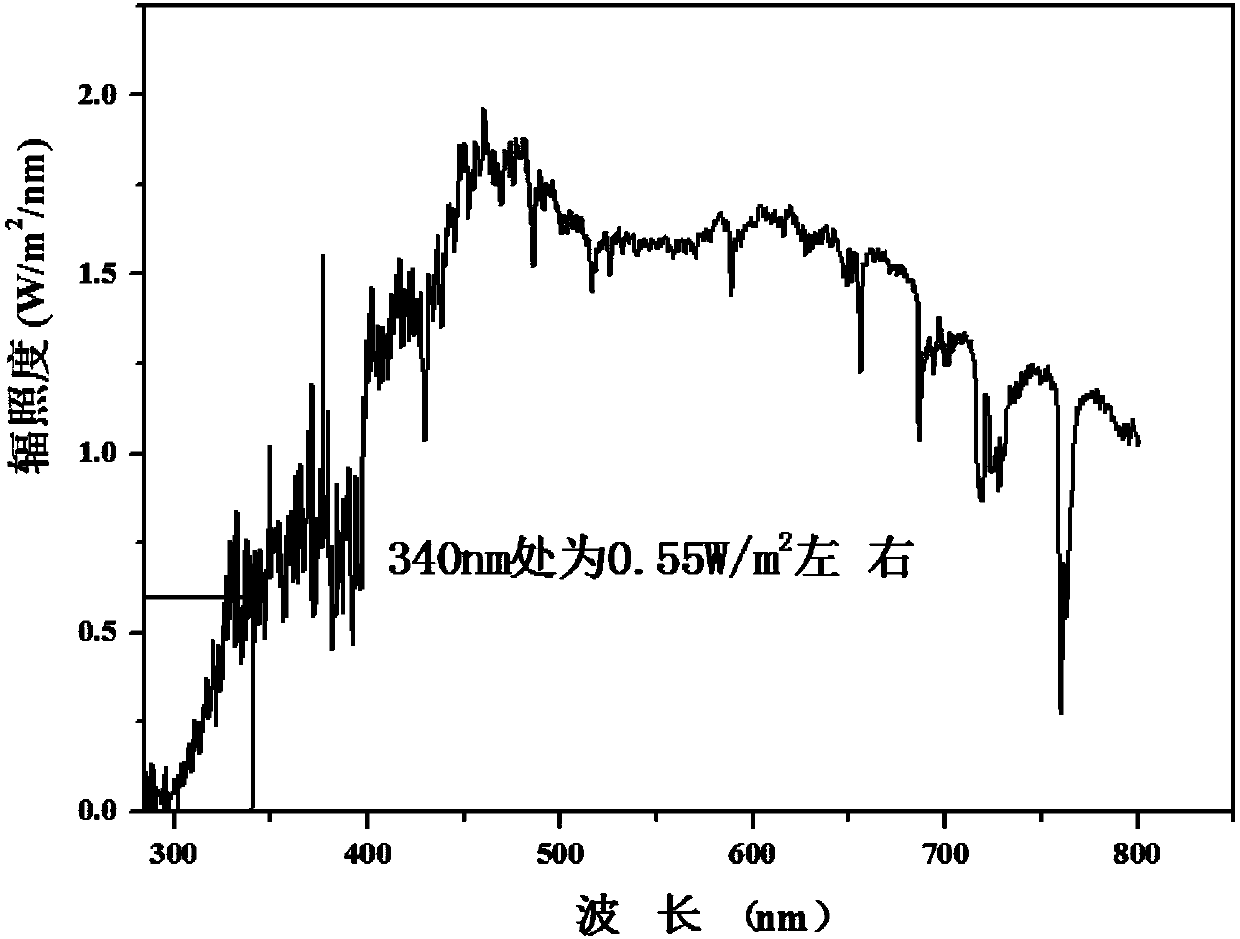

[0029] (1) Statistical analysis was carried out on the climatic and environmental conditions in Qionghai, Hainan, and the main climatic and environmental conditions affecting the aging of polymer materials in this area were obtained: radiation intensity, radiation amount, solar spectrum, ambient temperature, blackboard temperature and ambient humidity, solar spectrum such as figure 1 The rest of the environmental parameters are shown in Table 1.

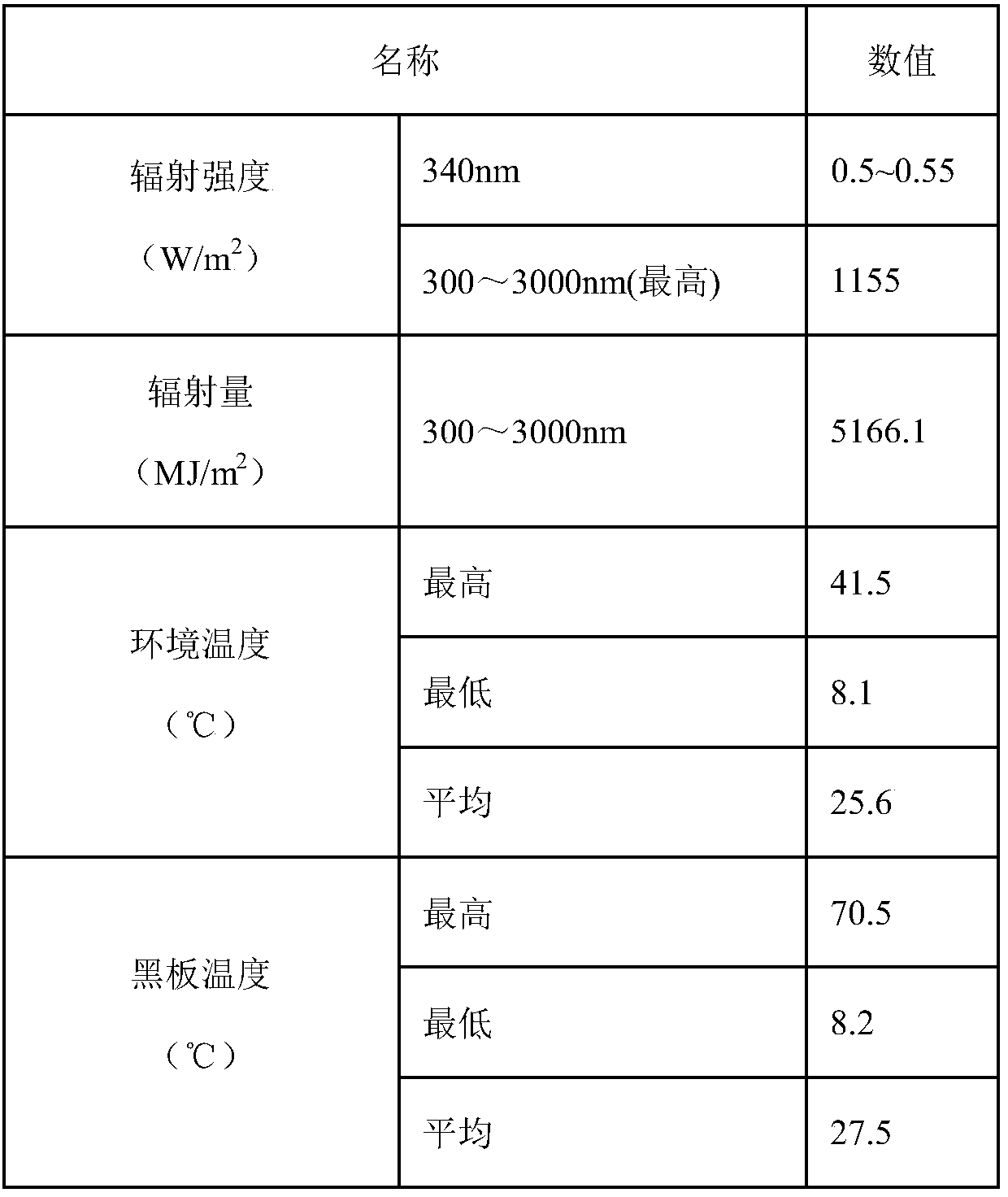

[0030] Table 1: Environmental parameters in Qionghai, Hainan

[0031]

[0032]

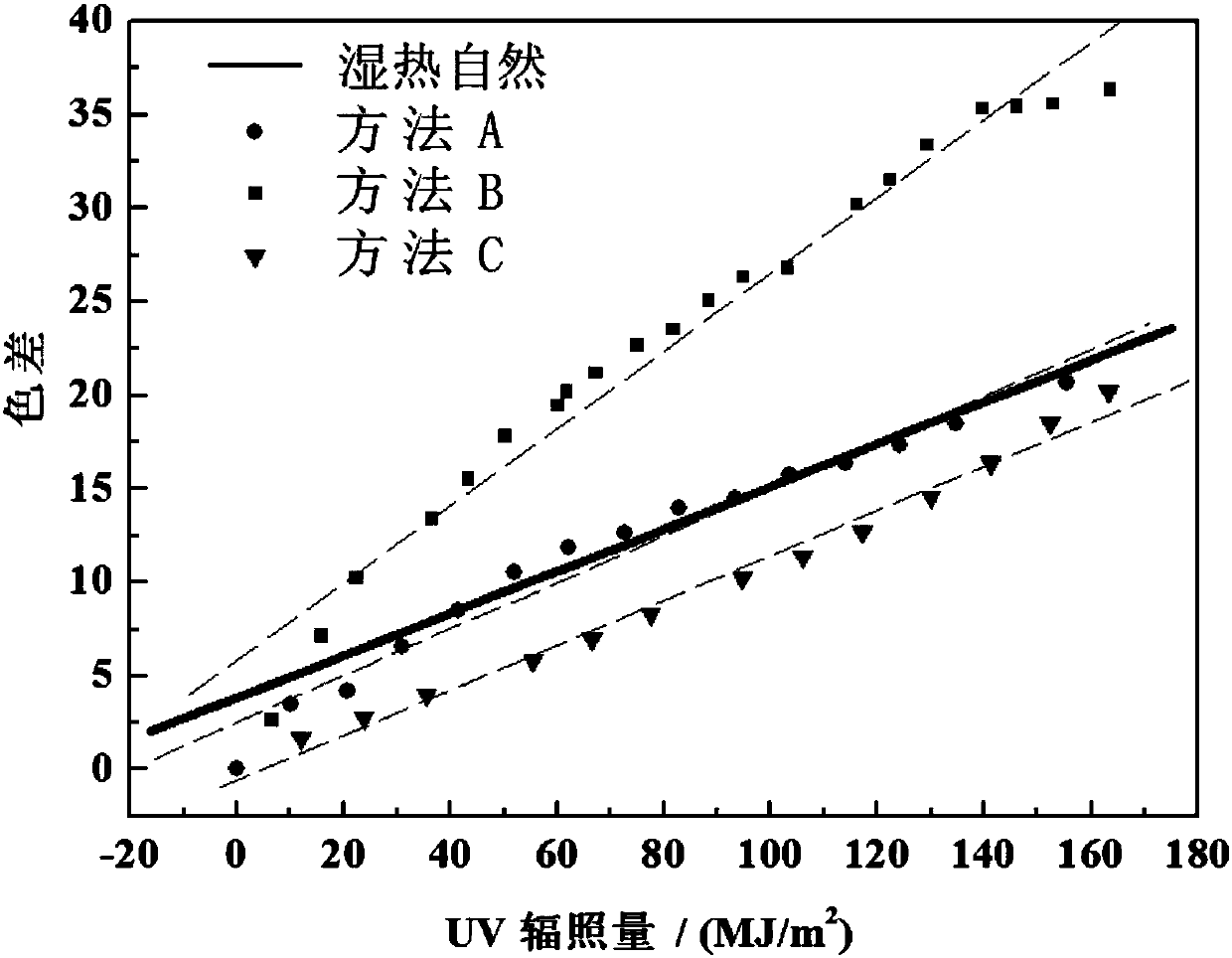

[0033] (2) According to the above environmental parameters, three xenon lamp accelerated aging tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com