Actuator assembly for electronic parking brake

An electronic parking brake and actuator technology, applied in the direction of brakes, brake components, brake transmissions, etc., can solve the problems of power transmission loss and noise, output shaft power loss, and overall alignment instability. Achieve the effect of improving durability and manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

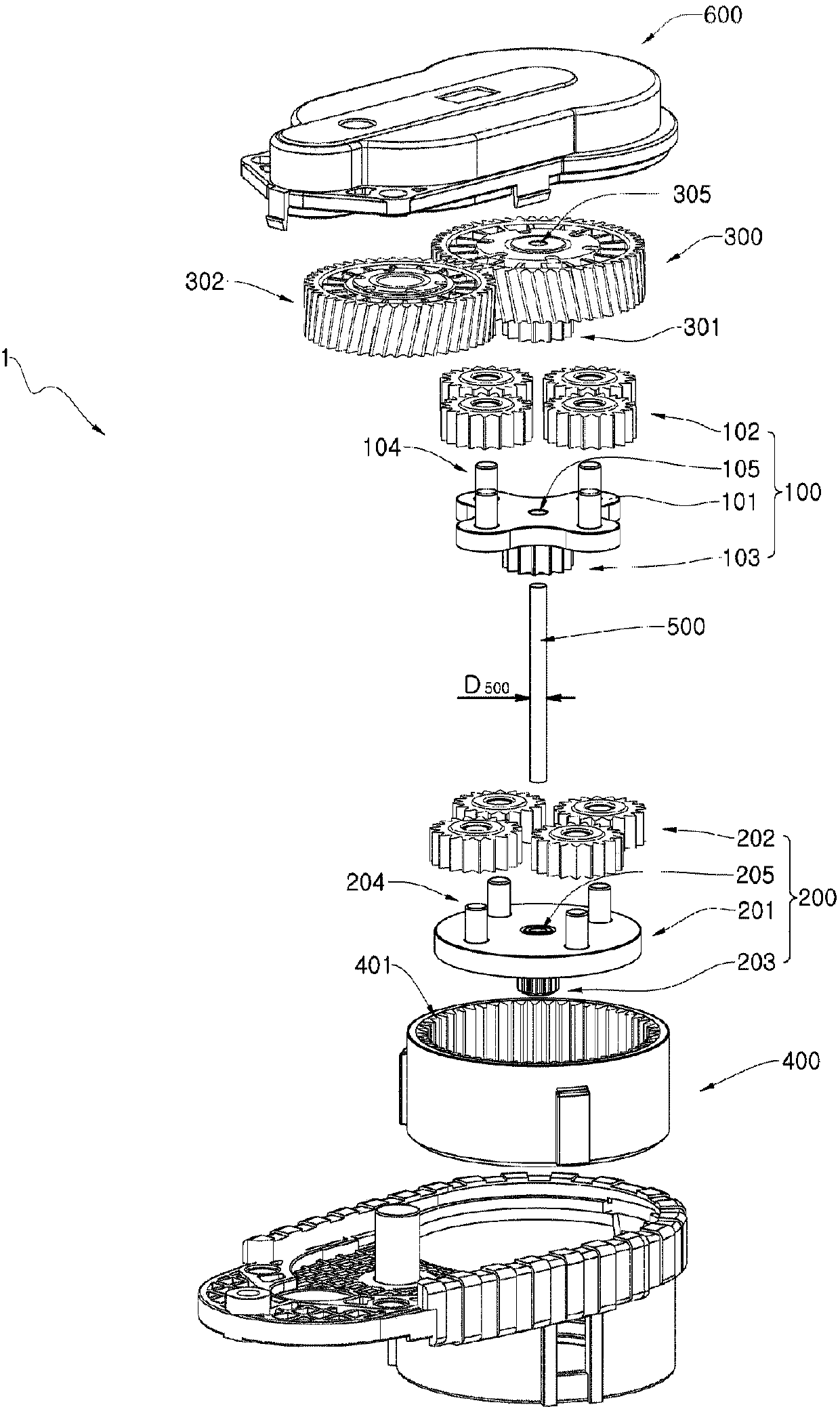

[0040] Hereinafter, an actuator assembly for an electric parking brake and an operation process thereof according to the present disclosure will be described through preferred embodiments of the present disclosure based on the accompanying drawings.

[0041] Before proceeding to the description, in many embodiments, the same elements having the same configuration are generally described using the same reference numerals in the embodiments, and in other embodiments only different elements are described.

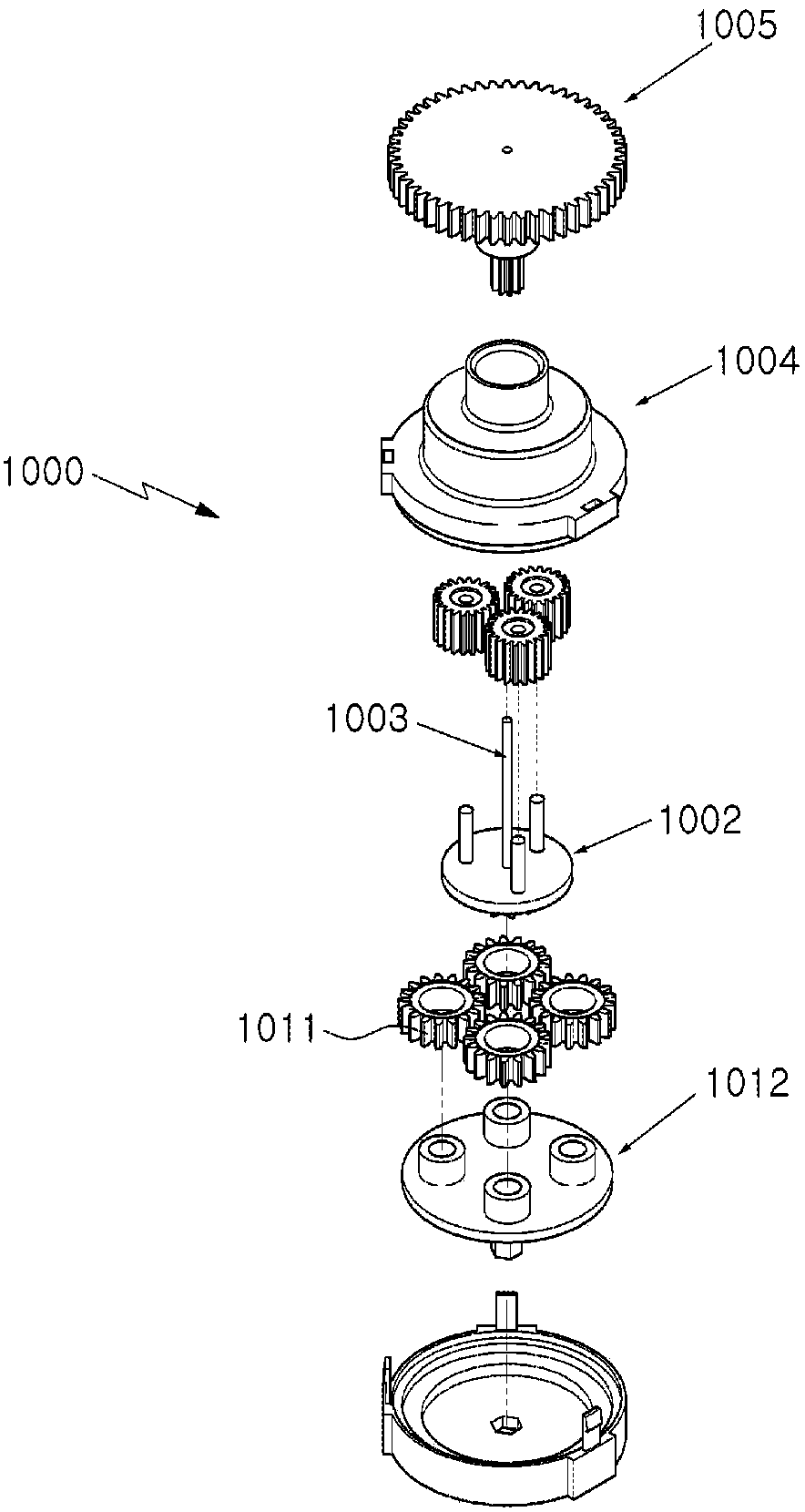

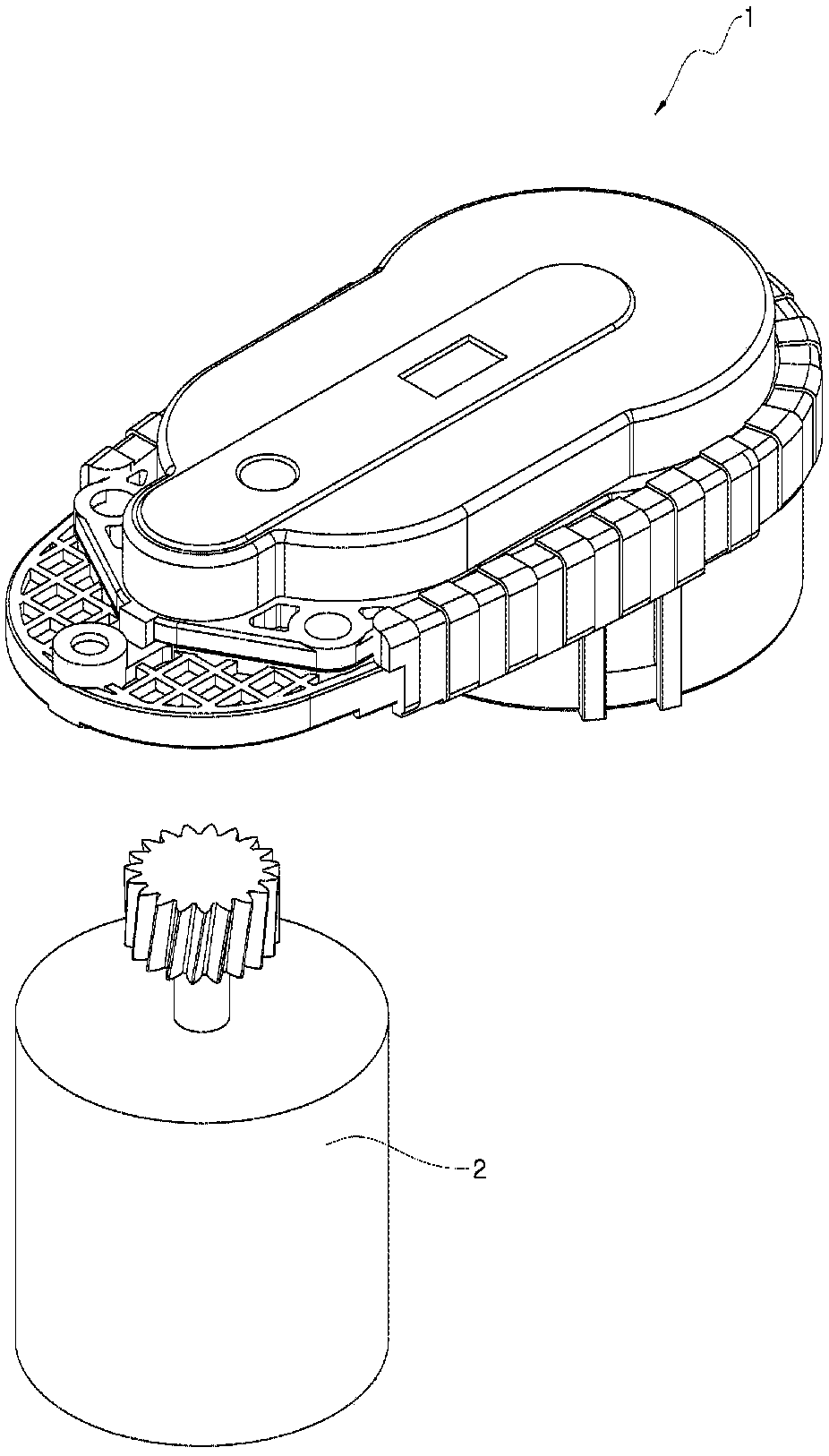

[0042] figure 2 is a perspective view schematically showing the appearance of the actuator according to the first embodiment of the present disclosure. Such as figure 2 As shown, according to the embodiment of the present disclosure, the driving device 2 for transmitting power is connected under one side of the actuator assembly 1 to supply power to the actuator assembly 1 .

[0043] The driving device 2 may include a rotary electric motor, and is electrically connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com