Waste beer recovery

A beer and alcohol technology, applied in beer brewing, beer fermentation methods, preparation of alcoholic beverages, etc., can solve problems such as influence, unfavorable flavor, beer microbial contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

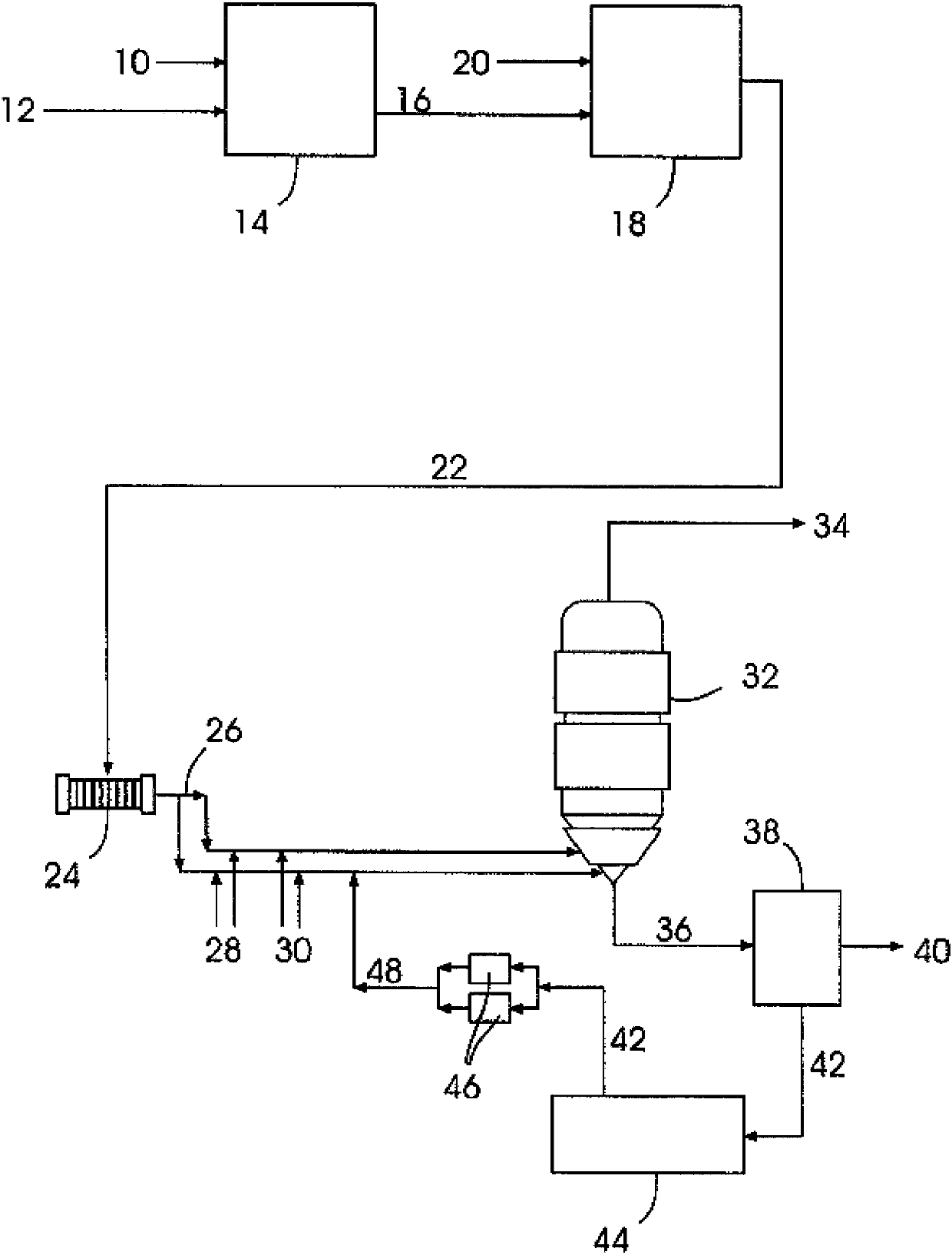

Method used

Image

Examples

example

[0041] 200 liters of conventionally hopped ale were brewed and fermented via standard brewing practices. The resulting beer exhibits a hoppy and slightly bitter character (from the hops) with notes of caramel from the particular malt used. Once the fermentation was complete, the contents of the fermentation vessel (FV) were cooled to 8°C to allow some flocculation of the yeast. Spent yeast was removed via the bottom FV outlet valve. The recovered beer separated from the spent yeast was then sterilized with UV light in a light sterilization unit as described in US 6,916,452. Dosing of UV light was achieved by connecting the supply and return hoses from the FV to the light sterilization unit, delivering 100 Joules / liter / product through. These hoses and units were CIPed prior to testing to prevent any microbial contamination. The beer was circulated through the unit at 2000 L / hr for 2 hours without measuring total UV exposure (this was calculated as 120 000 J / L exposure). Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com