3D printing device

A 3D printing and printing mechanism technology, applied in the field of 3D printing, can solve the problems of single product color, single function, low printing efficiency, etc., to achieve the effect of ensuring diversification, ensuring functions, and improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

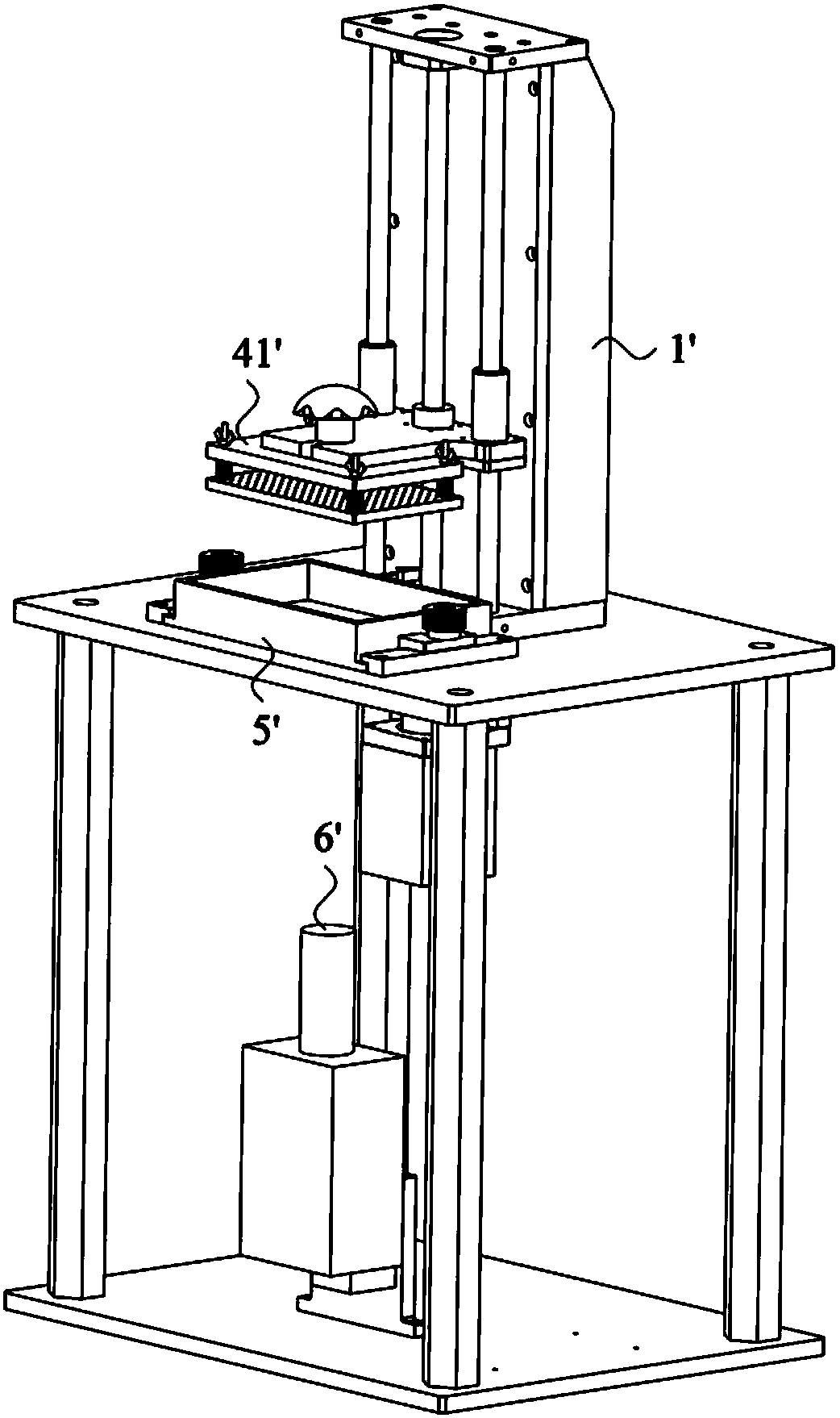

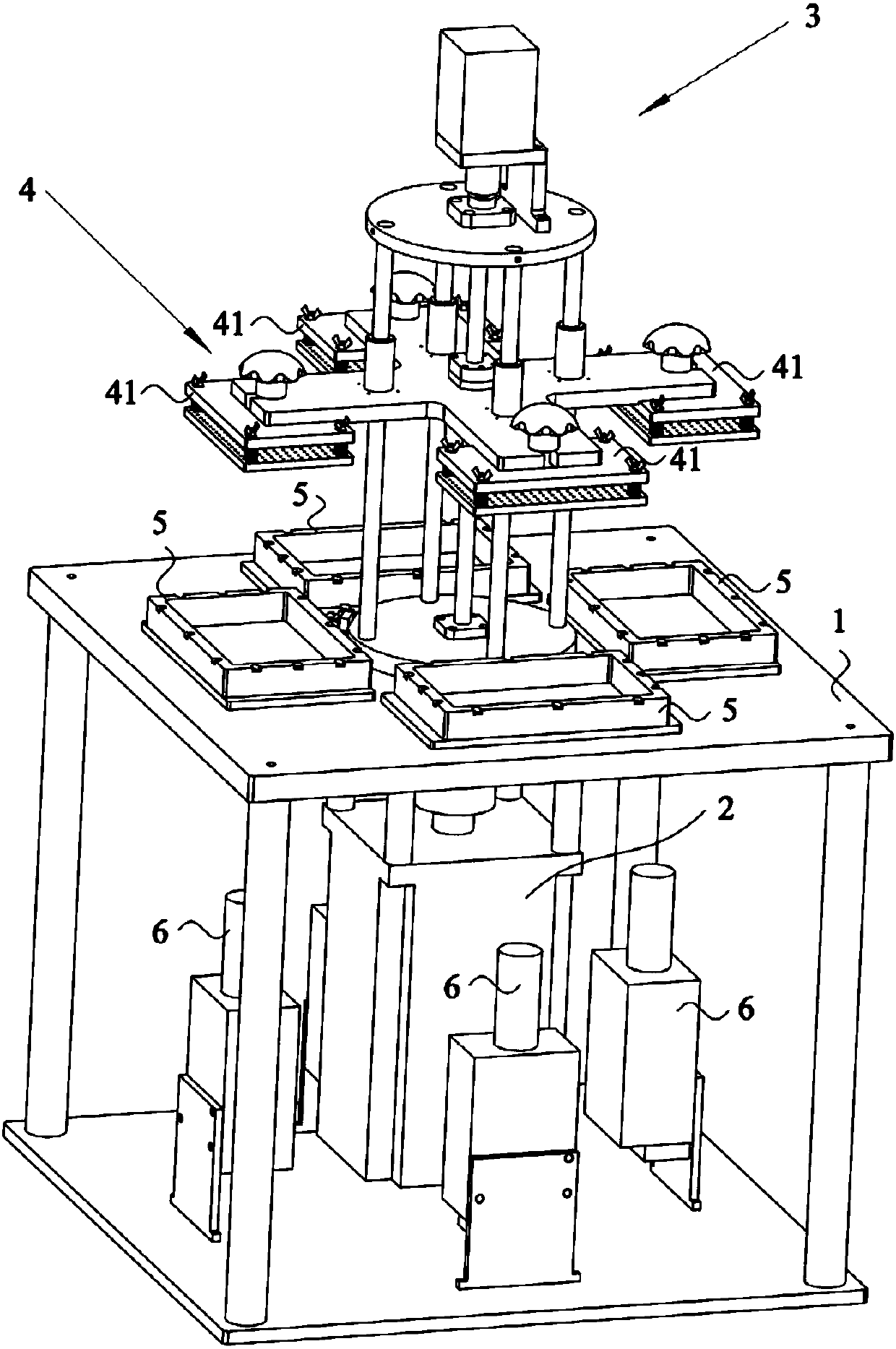

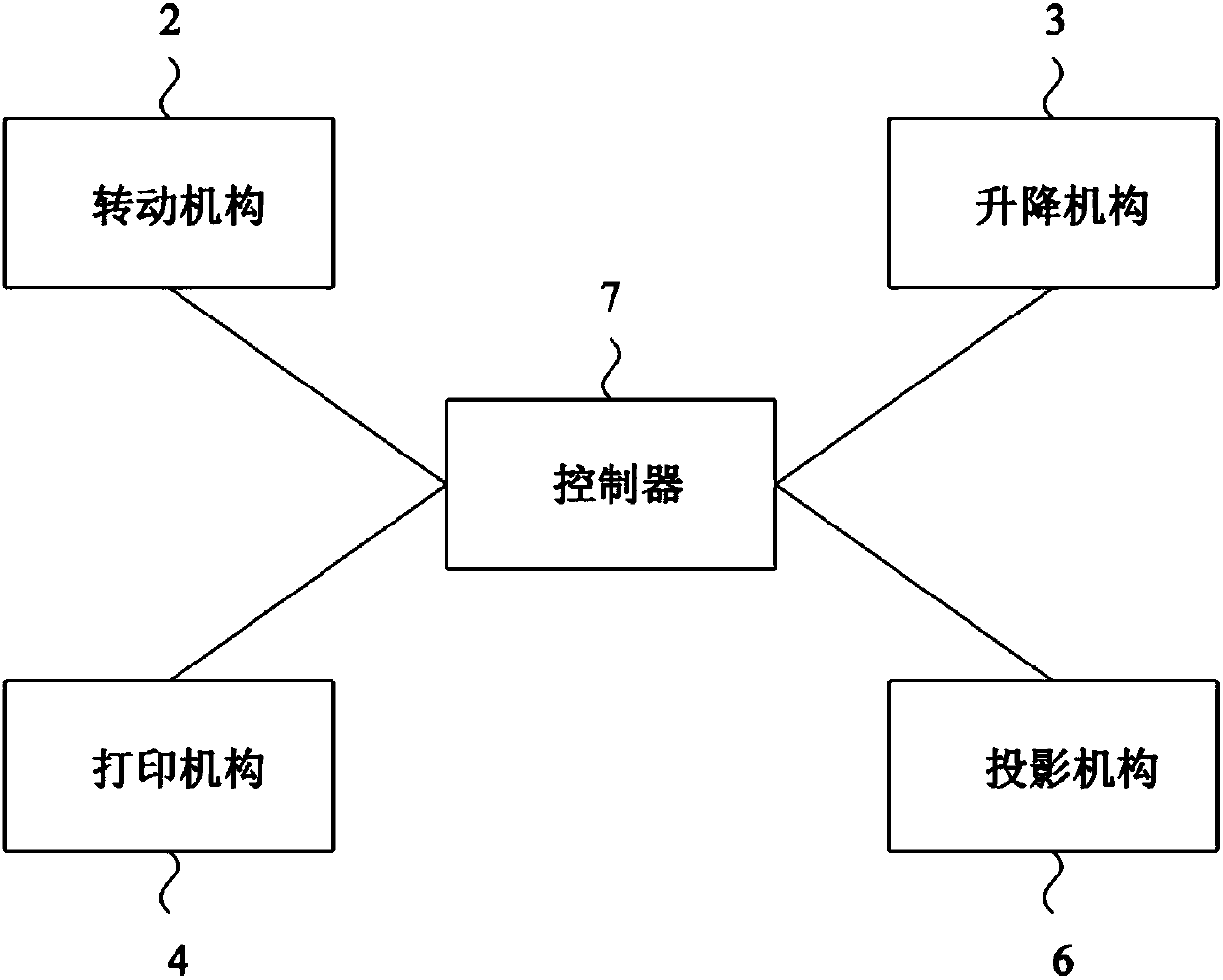

[0044] In this example, if figure 2 As shown, the 3D printing device includes a frame 1 , a rotating mechanism 2 , a lifting mechanism 3 , a printing mechanism 4 , a plurality of trays 5 and a projection mechanism 6 . Wherein, the rotating mechanism 2, a plurality of trays 5, and the projection mechanism 6 are all arranged on the frame 1, the lifting mechanism 3 is arranged on the rotating mechanism 2, and the printing mechanism 4 is slidably arranged along the lifting mechanism 3, and includes a plurality of printing platforms 41 A plurality of trays 5 are correspondingly arranged under the plurality of printing platforms 41 , and each projection mechanism 6 is arranged under the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com