A kind of reversible swellable starch prepared by first high crosslinking and then high temperature water bath treatment and method

A high-temperature water, high-crosslinking technology, applied in the field of expanded starch, can solve the problems of high viscosity, unfavorable industrial production, large amount of ethanol and alkali, etc., and achieve the effect of excellent product quality, good product quality and zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) In 1000 g of corn starch milk with a mass concentration of 45%, adjust the pH value of the starch milk to 12 with 1M sodium hydroxide solution at 30°C, and then add anhydrous sodium sulfate accounting for 1% of the dry weight of the starch , keep stirring for 30min for pre-expansion;

[0044] (2) Add STMP / STPP (sodium trimetaphosphate / sodium tripolyphosphate, the mass ratio of STMP to STPP is 99:1) with 1% starch mass in step (1) and keep for 180min;

[0045] (3) Add 1M HCl (hydrochloric acid) to step (2) to adjust the pH of the starch milk to 6.5, and add water (tap water is enough) to adjust the mass concentration of the starch milk to 20%;

[0046] (4) Treat the starch milk after step (3) in a boiling water bath for 15 minutes;

[0047] (5) Wash the sample twice by centrifugation with water and ethanol respectively, and dry at 45°C until the water content is less than 10%;

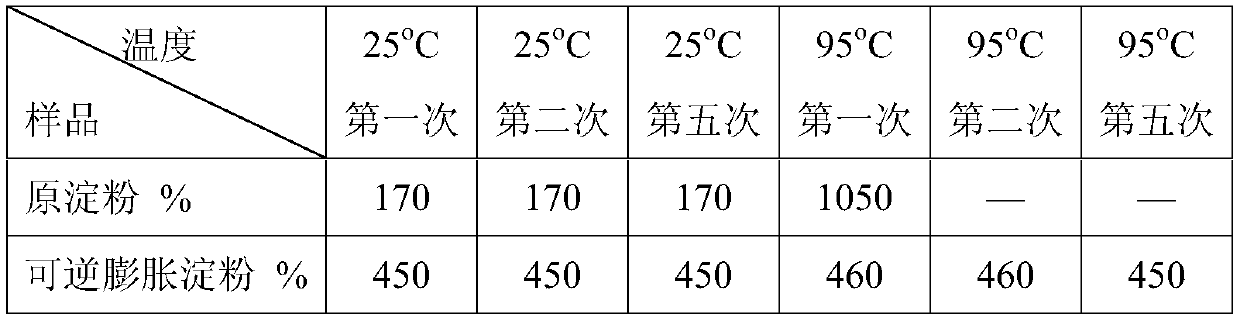

[0048] (6) Pulverize to uniform white particles and pass through a 100-mesh sieve to ob...

Embodiment 2

[0059] (1) In the pea starch milk with a mass concentration of 30%, adjust the pH value of the starch milk to 11 with 1M sodium hydroxide solution at 60°C, and then add anhydrous sodium sulfate accounting for 10% of the dry weight of the starch, Pre-expansion was maintained for 180 minutes under constant stirring;

[0060] (2) STMP / STPP (sodium trimetaphosphate / sodium tripolyphosphate, 99:1) with 12% starch mass was added to step (1) and kept for 120 min;

[0061] (3) Add 1M HCl (hydrochloric acid) to step (2) to adjust the pH of the starch milk to 6.5, and add water (tap water is sufficient) to adjust the mass concentration of the starch milk to 10%;

[0062] (4) Treat the starch milk after step (3) in a boiling water bath for 60 minutes;

[0063] (5) Wash the sample twice by centrifugation with water and ethanol respectively, and dry at 45°C until the water content is less than 10%;

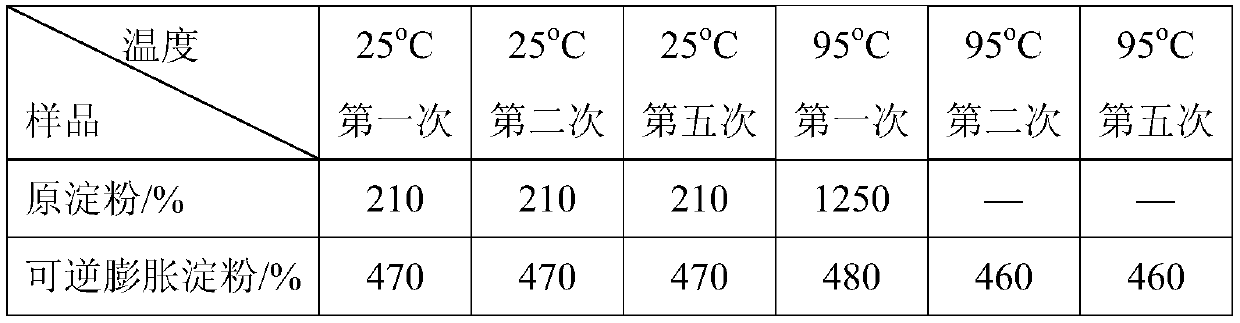

[0064] (6) Pulverize to uniform white particles and pass through a 100-mesh sieve to obta...

Embodiment 3

[0072] (1) In the waxy cornstarch milk with a mass concentration of 35%, adjust the pH value of the starch milk to 11.5 with 1M sodium hydroxide solution at 40°C, and then add anhydrous sulfuric acid accounting for 5% of the dry weight of the starch Sodium, keep stirring for 120min for pre-expansion;

[0073] (2) Add STMP / STPP (sodium trimetaphosphate / sodium tripolyphosphate, 99:1) with 4% starch quality to step (1) and keep for 120min;

[0074] (3) Add 1M HCl (hydrochloric acid) to the step (2) to adjust the pH of the starch milk to 6.5, and add water (just tap water) to adjust the concentration of the starch milk to 15%;

[0075] (4) Treat the starch milk after step (3) in a boiling water bath for 30 minutes;

[0076] (5) Wash the sample twice by centrifugation with water and ethanol respectively, and dry at 45°C until the water content is less than 10%;

[0077] (6) Pulverize to uniform white particles and pass through a 100-mesh sieve to obtain a sample.

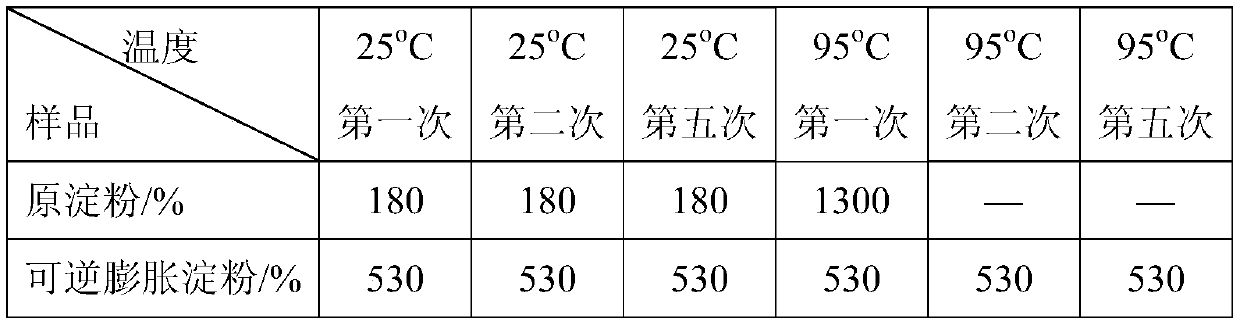

[0078] The reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com