Quantum dot polaroid assembly of quantum dot liquid crystal display device

A liquid crystal display device and quantum dot technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of low color gamut level and poor viewing effect of liquid crystal displays, achieve better optical performance, optimize display effect, use Life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

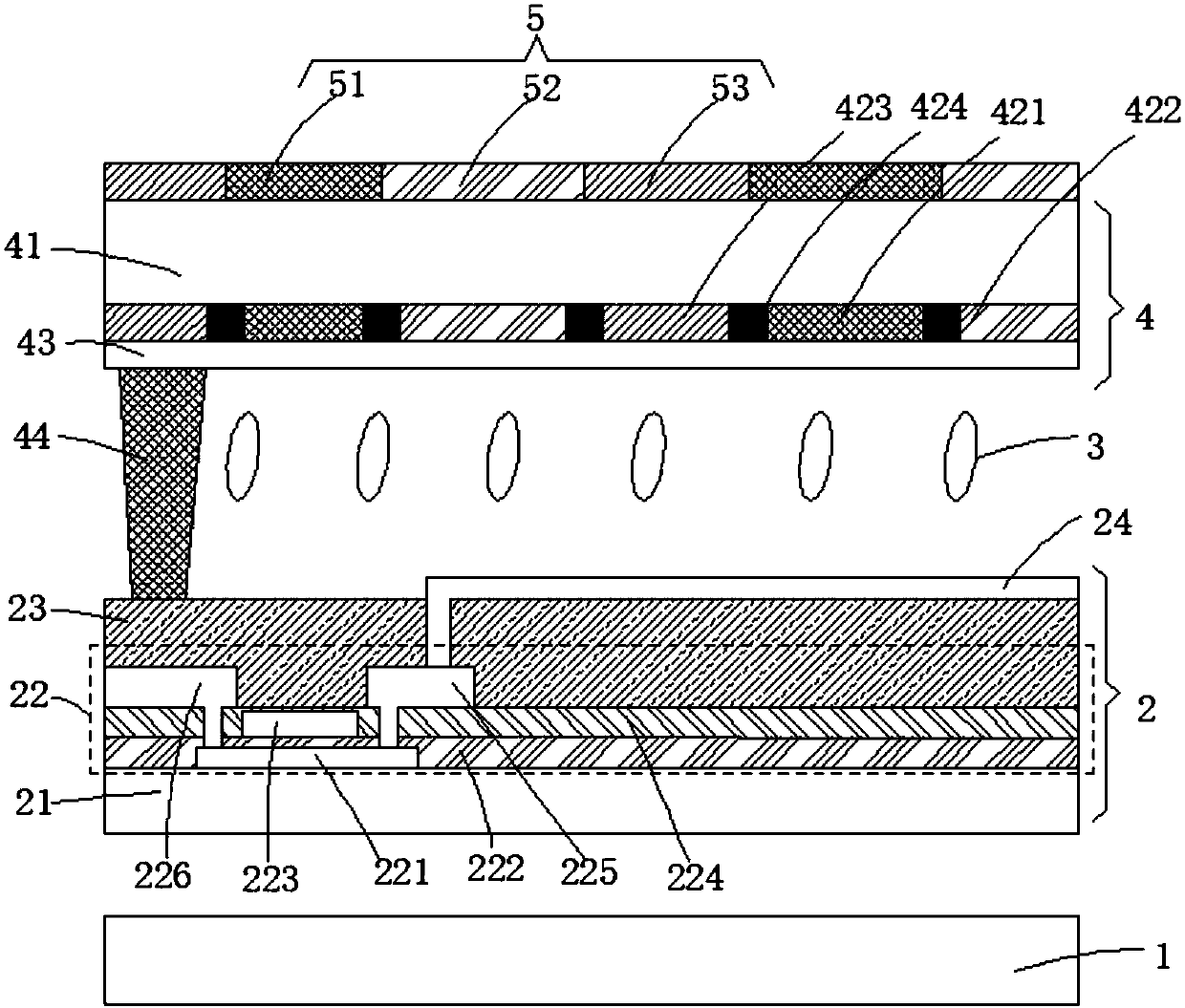

[0028] see figure 1 , the present invention provides a quantum dot liquid crystal display device, comprising: a liquid crystal display panel, and a backlight module 1 arranged under the liquid crystal display panel;

[0029] The liquid crystal display panel includes: an array substrate 2 and a color filter substrate 4 oppositely arranged, a liquid crystal layer 3 arranged between the array substrate 2 and the color filter substrate 4, and a liquid crystal layer 3 arranged on the color filter substrate 4 away from the The quantum dot polarizer 5 on one side of the array substrate 2; the color filter substrate 4 includes: a first base substrate 41, a plurality of The color resistance block, the black matrix 424 separating the color resistance blocks, the common electrode 43 arranged on the side of the color resistance block and the black matrix 424 close to the array substrate 2, and supporting the color filter substrate 4 and the array The gap spacer 44 of the substrate 2; the...

Embodiment 2

[0036] A processing technology of a quantum dot polarizer assembly of a quantum dot liquid crystal display device, the steps are as follows:

[0037] 1), structure and separate processing

[0038] The quantum dot polarizer assembly is located on the side of the color filter substrate away from the array substrate, including a first quantum dot area corresponding to the red color resistance block, a second quantum dot area corresponding to the green color resistance block, and a blue color resistance block. The third quantum dot area corresponding to the block;

[0039] The processing of quantum dot polarizer components is carried out according to the existing technology;

[0040] 2), pretreatment

[0041] Using electrostatic spraying method, spray the pretreatment liquid on the outer surface of the quantum dot polarizer assembly, after the spraying is completed, leave it at room temperature for more than 48 hours;

[0042] The components of the pretreatment solution are: 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com