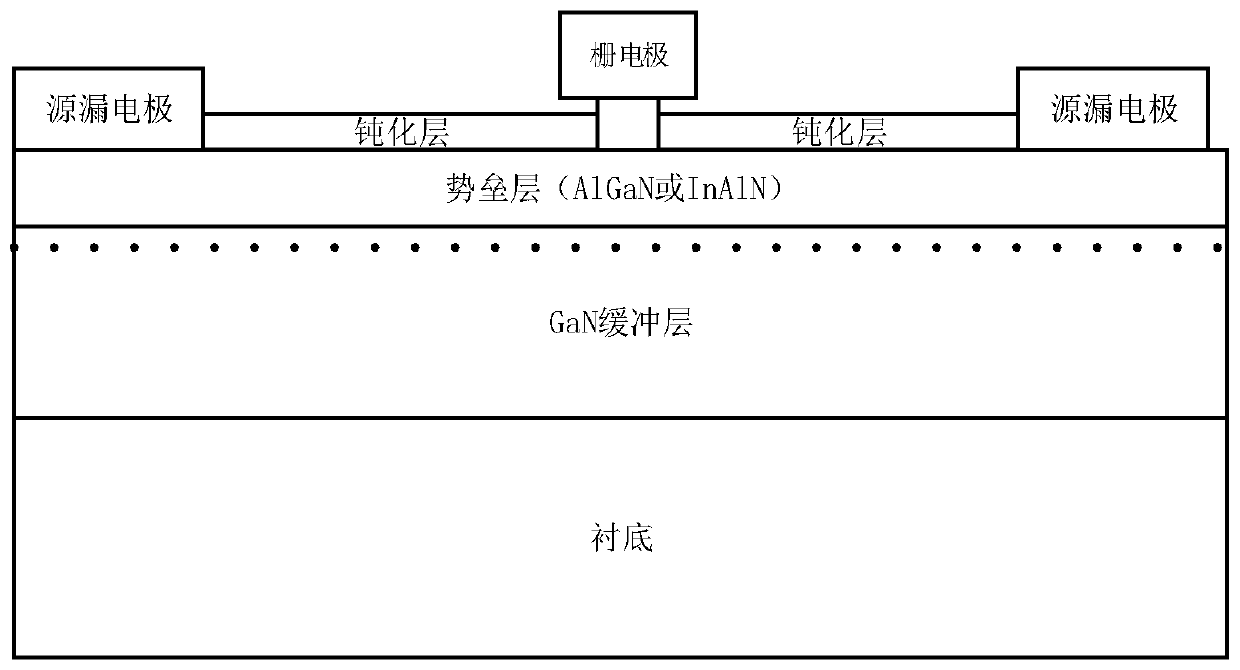

An electron beam lithography method for fabricating a T-type grid structure

A technology of electron beam lithography and grid structure, which is applied in the field of microwave communication, can solve problems such as process failure, and achieve the effects of avoiding developer incompatibility, avoiding peeling failure, convenient and reliable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

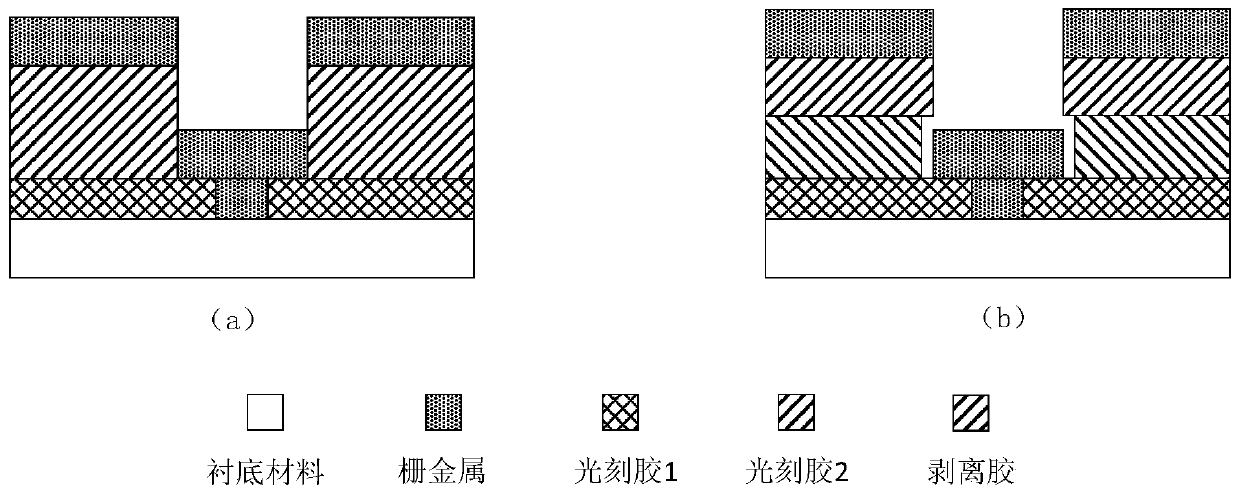

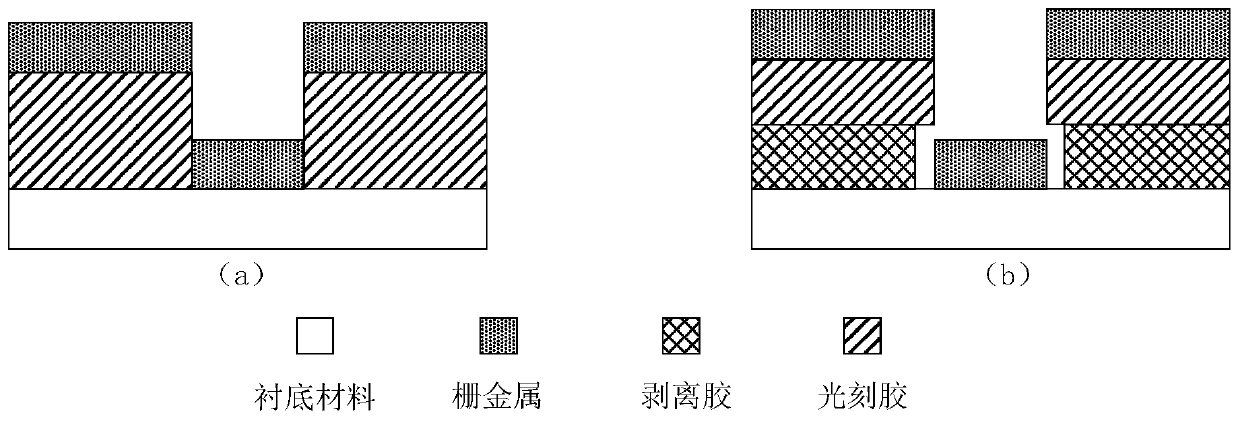

[0033] see Figure 4 , the present invention makes the electron beam lithography method of T-shaped grid structure and comprises the following steps:

[0034] 1. On the substrate material, coat No. 1 photoresist and bake at 180°C for 2 minutes. The photoresist uses PMMA glue, which has the characteristics of low sensitivity and high photoresist dose; the substrate material adopts GaN-based heterojunction planar materials;

[0035] 2. Coating No. 2 photoresist, the photoresist is PMMA-MAA glue, and baked at 200°C for 5 minutes. The sensitivity of PMMA-MAA glue is higher than that of PMAA glue, and the photoresist dose is lower than that of PMMA glue;

[0036] 3. Coating No. 3 photoresist, this photoresist still adopts PMMA-MAA glue and bakes, and this baking temperature will be lower than No. 2 photoresist above 20 ℃, in the embodiment, bake 5 at 160 ℃ minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com