Machine tool observation window with smoke alarming function

A smoke alarm and observation window technology, which is applied in manufacturing tools, safety devices, metal processing equipment, etc., can solve the problems of high processing cost, long water spray pulverization time, poor pulverization effect, etc., and achieve high safety and maintenance Visible clarity, the effect of preventing the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

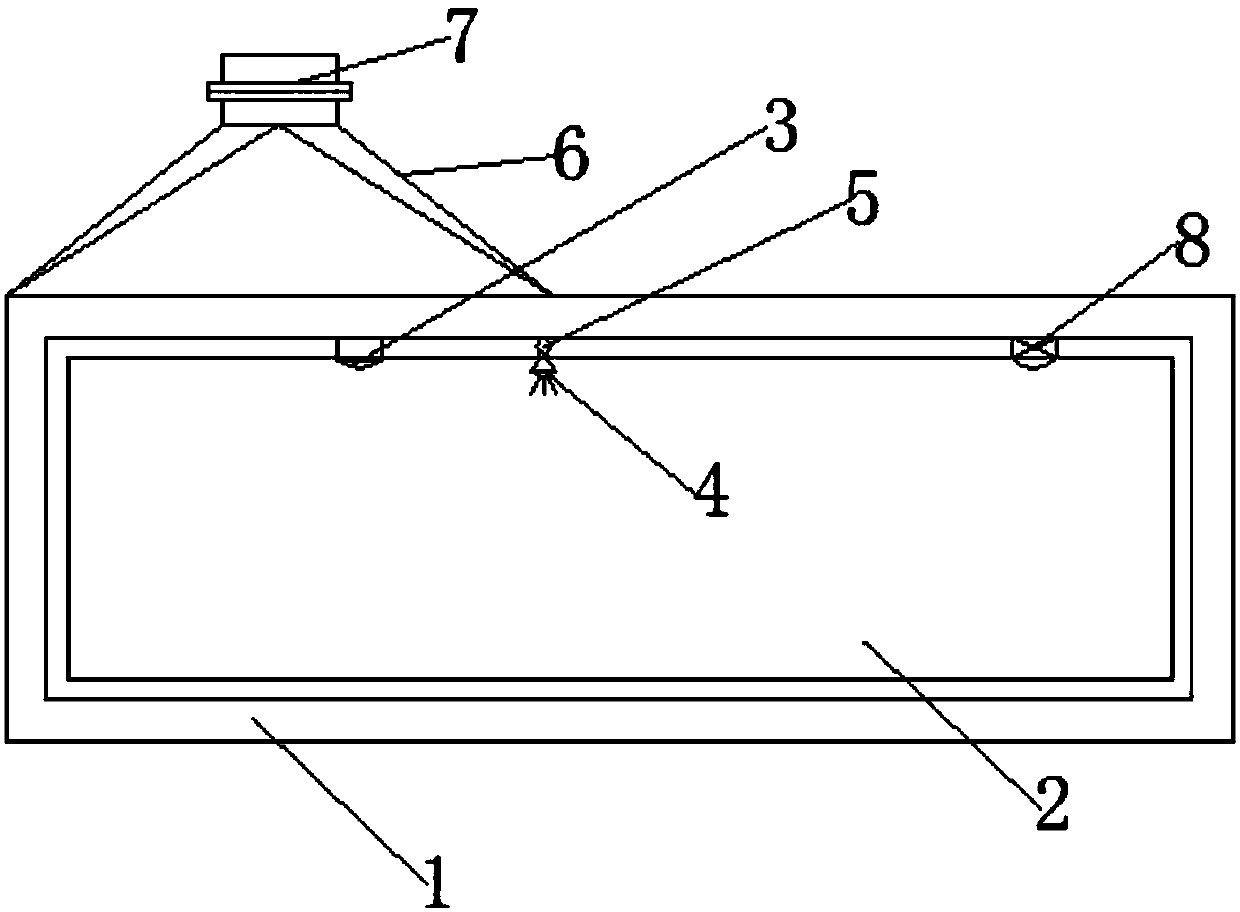

[0019] Such as figure 1 As shown, a machine tool observation window with smoke alarm function includes a groove-shaped aluminum alloy bracket 1 for covering the machine tool, and a transparent observation plate 2 is embedded on the side and top of the aluminum alloy bracket 1, and the observation plate 2 is provided with the smoke alarm device 3 that is positioned at aluminum alloy bracket 1 groove.

Embodiment 2

[0021] This embodiment is further defined on the basis of the above embodiments, the top of the observation plate 2 is provided with a fire extinguishing sprinkler 4 located in the groove of the aluminum alloy bracket 1, and the fire extinguishing sprinkler 4 is connected to the external input The water pipes are connected, and the fire extinguishing sprinkler head 4 is provided with a fire extinguishing controller 5 controlled by a smoke alarm device 3 .

[0022] Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0024] This embodiment is further defined on the basis of the above embodiments, the top of the observation board 2 is provided with a smoke extraction device 6 , and the smoke extraction device 6 is provided with a smoke extraction controller 7 controlled by the smoke alarm device 3 .

[0025] Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com