Submergible carrier

A vehicle and platform technology, applied in special-purpose ships, ships, motor vehicles, etc., can solve the problems of being attacked, equipment loss, etc., and achieve the effect of easy management, reducing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

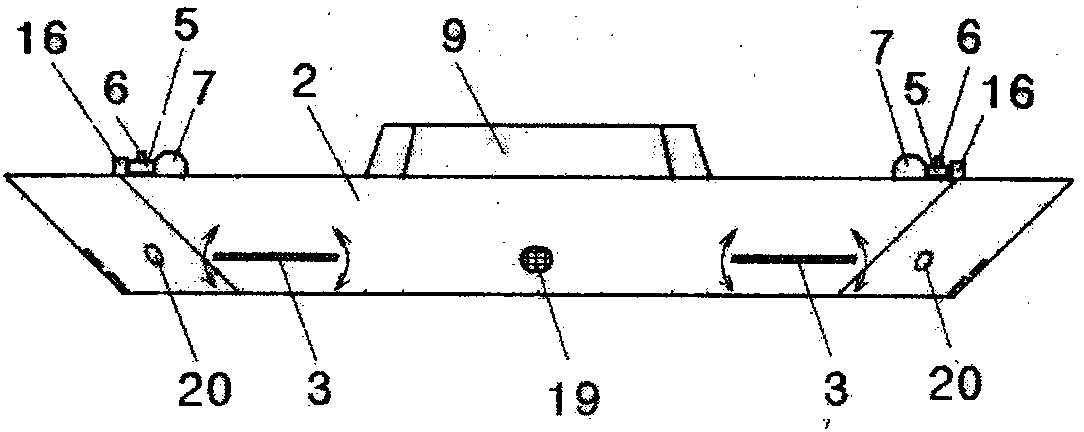

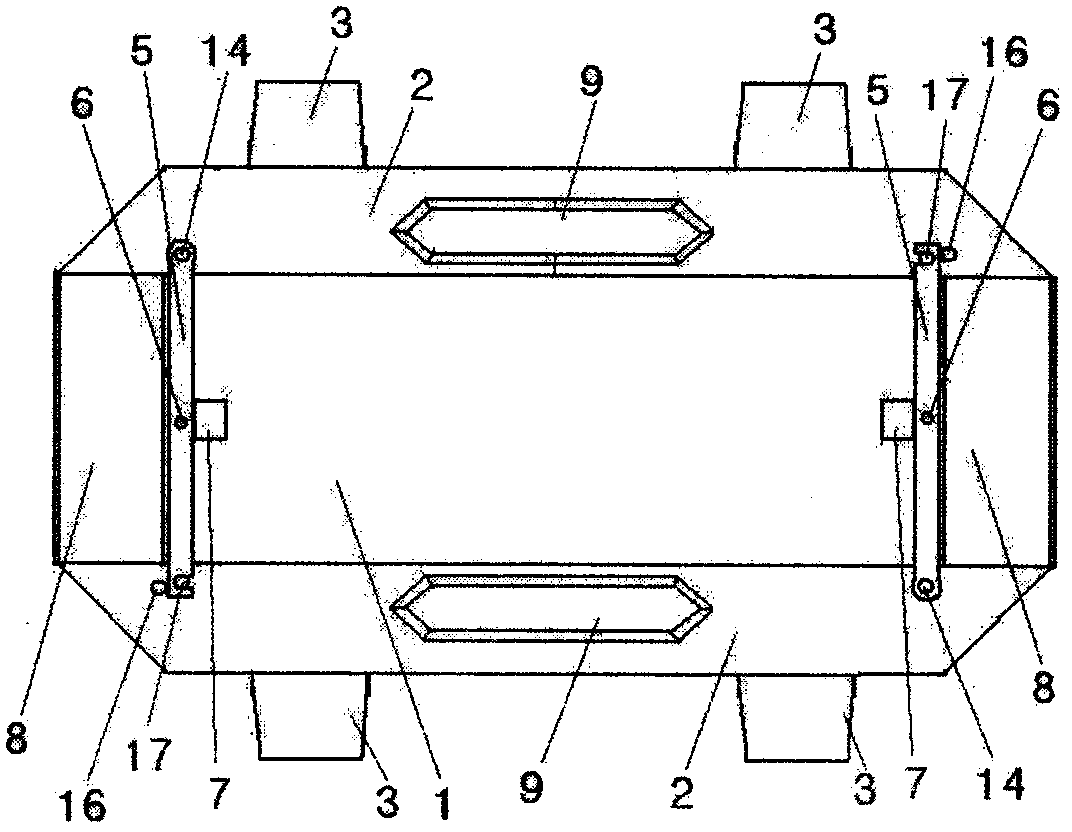

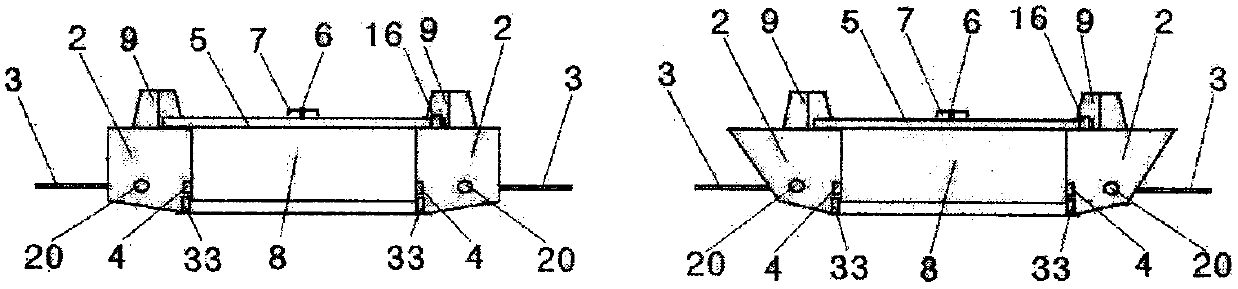

[0075] Embodiment 1: The submersible vehicle is characterized in that the cabin body 2 is on both sides of the bearing platform 1, the cabin body 2 is connected through the bearing platform 1 at the lower part or bottom, and the airfoil 3 is on the outside of the cabin body 2 , a general structure of which is Figure 1A to Figure 1D As shown, the cabins 2 on both sides of the vehicle and the bearing platform 1 in the middle are both front and rear symmetrical structures so that they have the same navigation capability. The shell of the cabin 2 and the surface of the bearing platform are made of steel or aluminum alloy materials, and the truss keel is Made of high-strength steel or aluminum alloy, the front and rear ends of the cabin are wedge-shaped or streamlined to reduce navigation resistance, but the top and the inner bulkhead are kept straight to ensure that the water flowing into the inner side and above the bearing platform is not loaded. When not being squeezed, only t...

Embodiment 2

[0099] Embodiment 2, the overall structure is the same as above, but a large-capacity battery pack is installed in the power cabin and a pure electric drive is used to drive the water pump. It is simple, but basically the distance from the towing ship to the towing ship after loading on the beach, and then from the towing ship to seizing the enemy's beach is not too far, so the capacity of the battery pack is sufficient to support the required power. One advantage of this solution is that it is pure Electric propulsion does not need to provide air to the engine and set up a snorkel, so it is more suitable to use a higher-power electric main engine to achieve a speed sufficient to rely on hydrofoil to maintain a submersible under the condition of sacrificing some of the voyage performance of the vehicle's autonomous power, so that the vehicle After leaving the towing ship, it can still submerge underwater at a suitable depth to improve concealment safety; for the pure electric p...

Embodiment 3

[0100] Embodiment 3, when the designed load-bearing structure is strong enough, the vehicle does not use the movable reinforcement beam and the traction anchor point and traction machine on it, and the traction anchorage point 6 of the vehicle and the drawbar or tow cable is arranged on the side of the cabin body 2 Therefore, the towing rod or the tow cable 40 is divided into two lanes in a Y shape in front of the vehicle, and is respectively connected to the tow hook points on the two cabins. See the appendix of the manual. Figure 8B One more operation is required for hooking and disengaging, but when the tank is loaded and unloaded on the vehicle, there is no barrier of the movable beam. The traction steel cable 30 is fixed on the symmetrical position of the inner wall of the cabin on one side, and the steel cable 30 is articulated with the tank through the hook 38 with a pulley and the fixed pulley 39 fixed on the inner wall of the carrier cabin body 2 to make the traction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com