Device for on-line detection of particle properties in fluidized bed granulation process

A technology of fluidized bed granulation and detection equipment, which is applied in the direction of measuring equipment, particle and sedimentation analysis, specific gravity measurement, etc. It can solve the problems of inability to meet the requirements of industrial production on-line monitoring, affect measurement results, and cumbersome operations, etc., and achieve reduction The detection speed and the requirements for additional cleaning accessories, the effect of improving the detection environment and avoiding human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

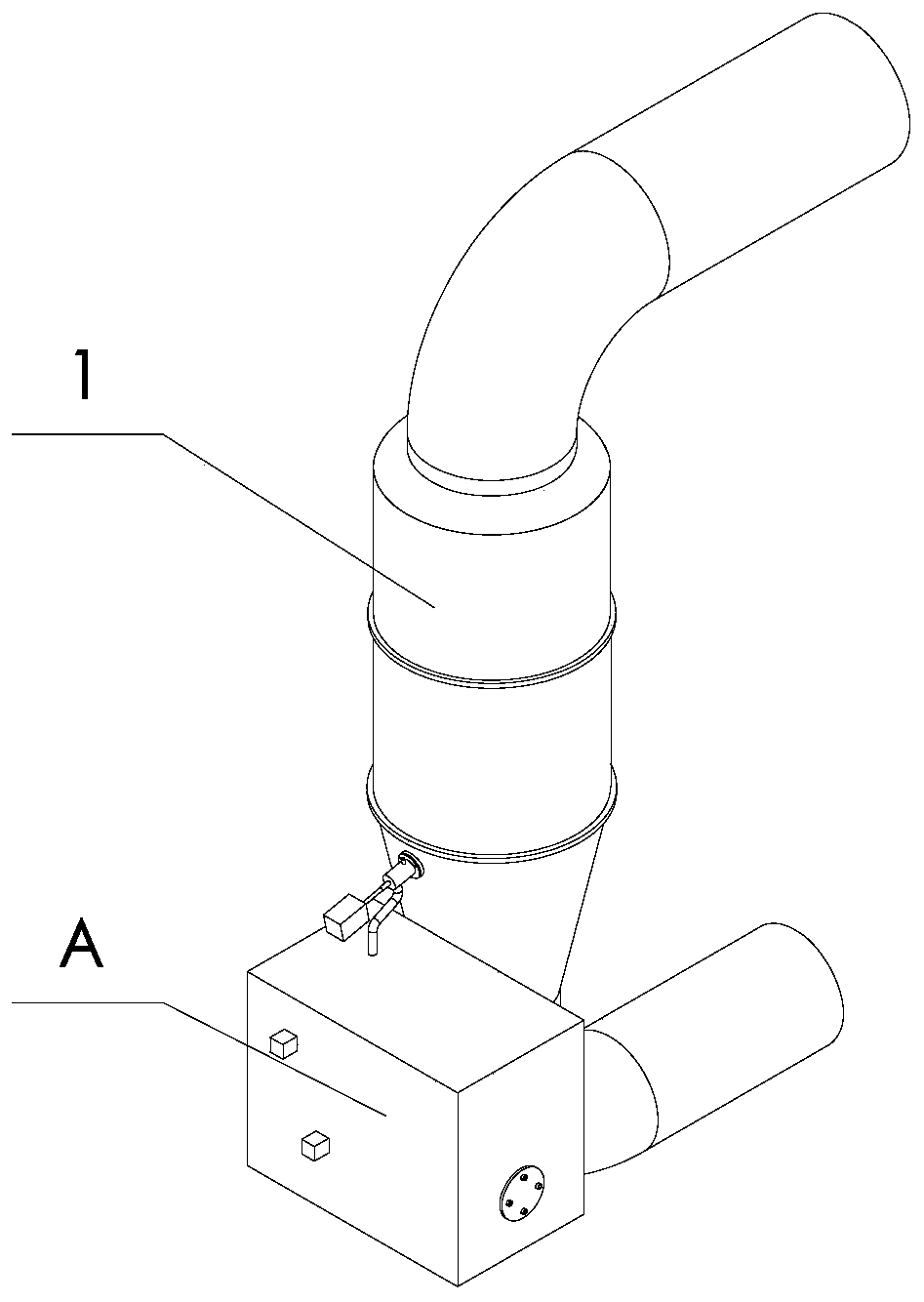

[0036] Such as figure 1 As shown, the on-line detection device used to test the particle properties in the fluidized bed granulation process, the detection device A is installed outside the fluidized bed reaction chamber 1; the detection device A has a sealed shell and can take out samples from the reaction chamber 1 sample collection agency.

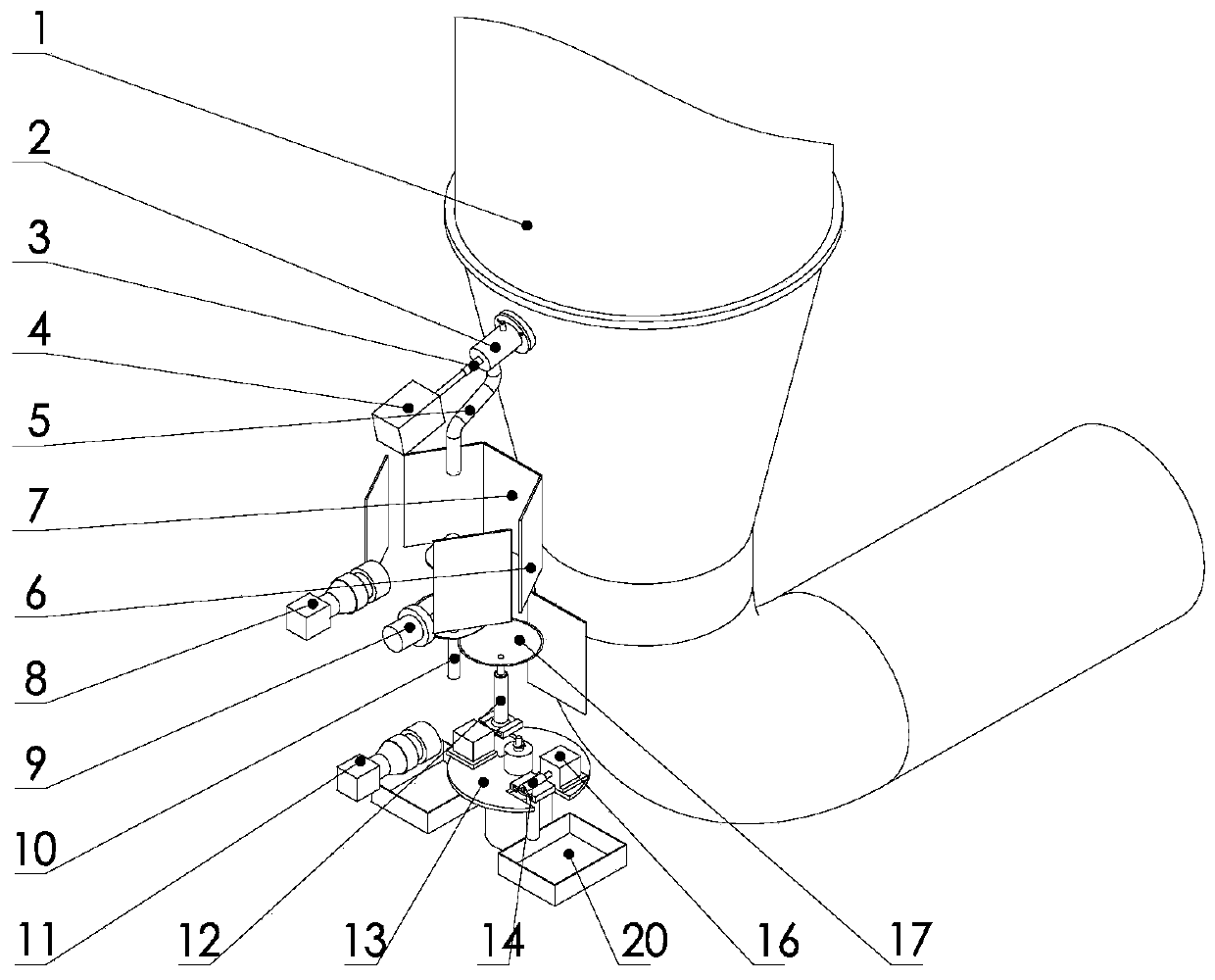

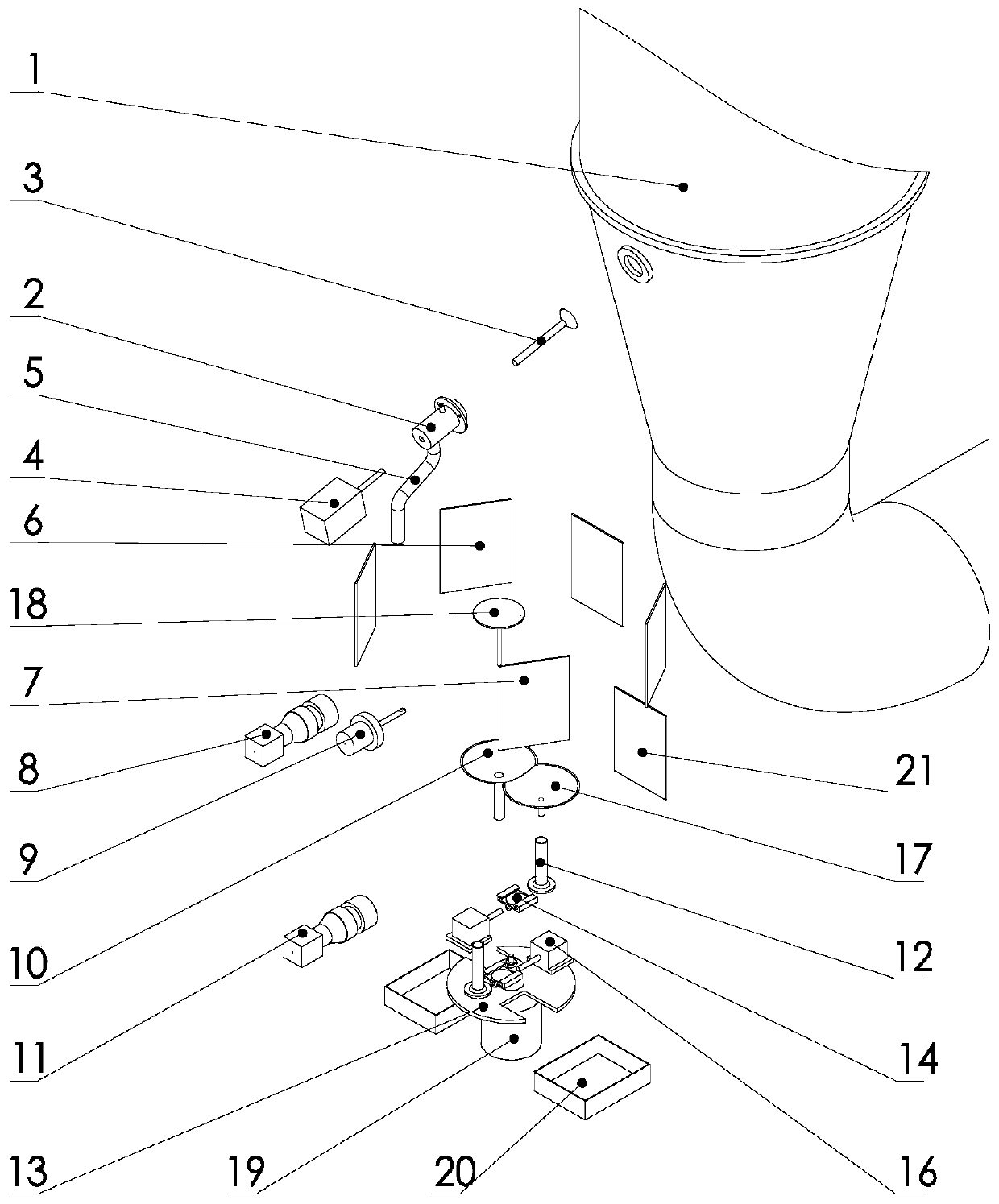

[0037] Such as figure 2 As shown, the casing is provided with a first visual detection unit that photographs the falling process of the sample taken out in the casing; the casing is equipped with a second visual detection unit that detects the bulk density and tapped density of the sample, and the sample is transferred from the sample The mechanism is transferred from the first visual detection unit to the second visual detection unit, and the image information obtained by the first visual detection unit and the second visual detection unit is input into the image processing system.

[0038] Such as figure 2 As shown, the sample co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com