Low temperature chemical strengthening process for glass

A glass and chemical technology, applied in the field of low-temperature technology, can solve the problems of glass visual properties, corrosiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Example

[0044] Embodiments are further illustrated using the following examples, which are illustrative only and do not limit the scope of the present disclosure.

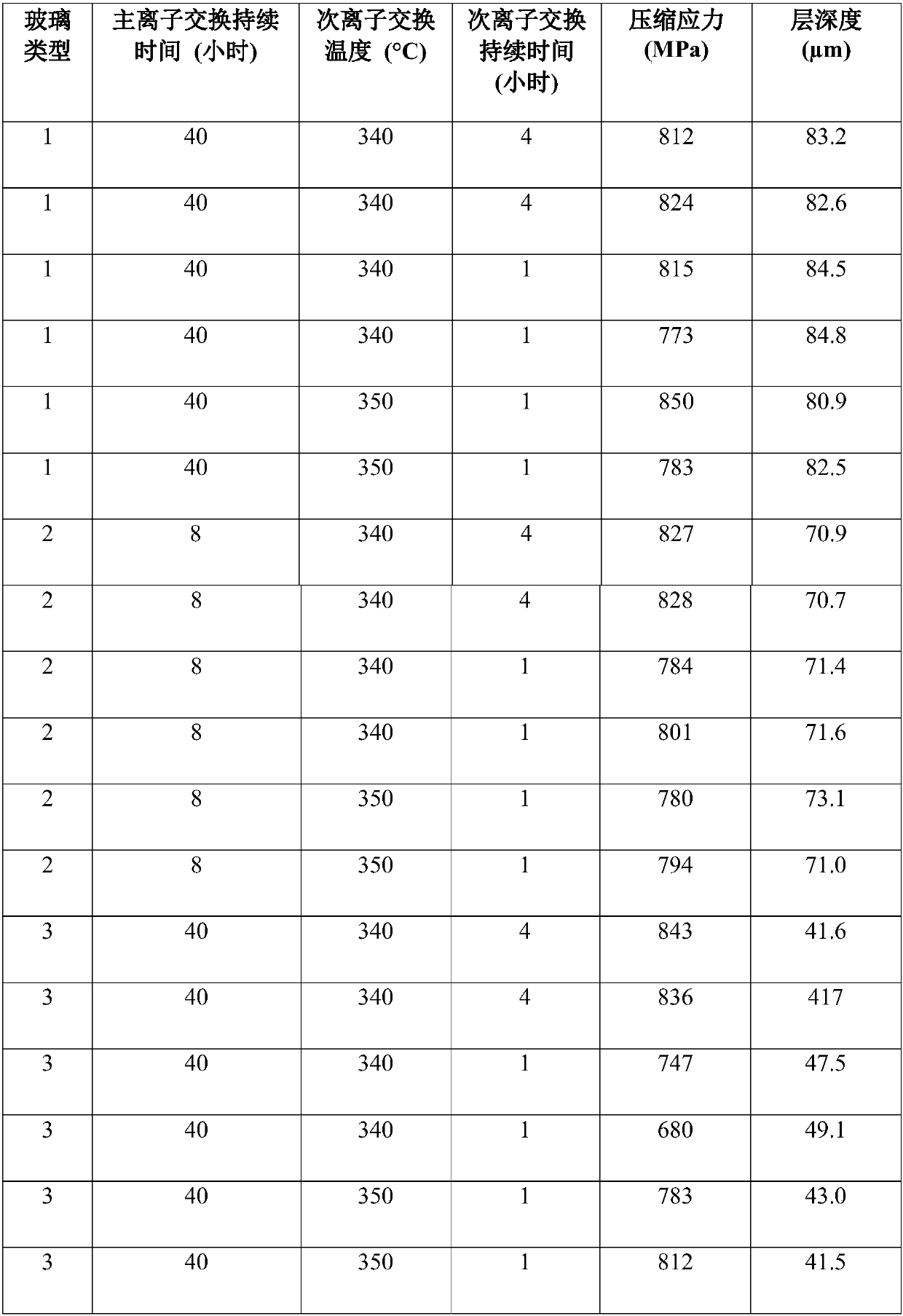

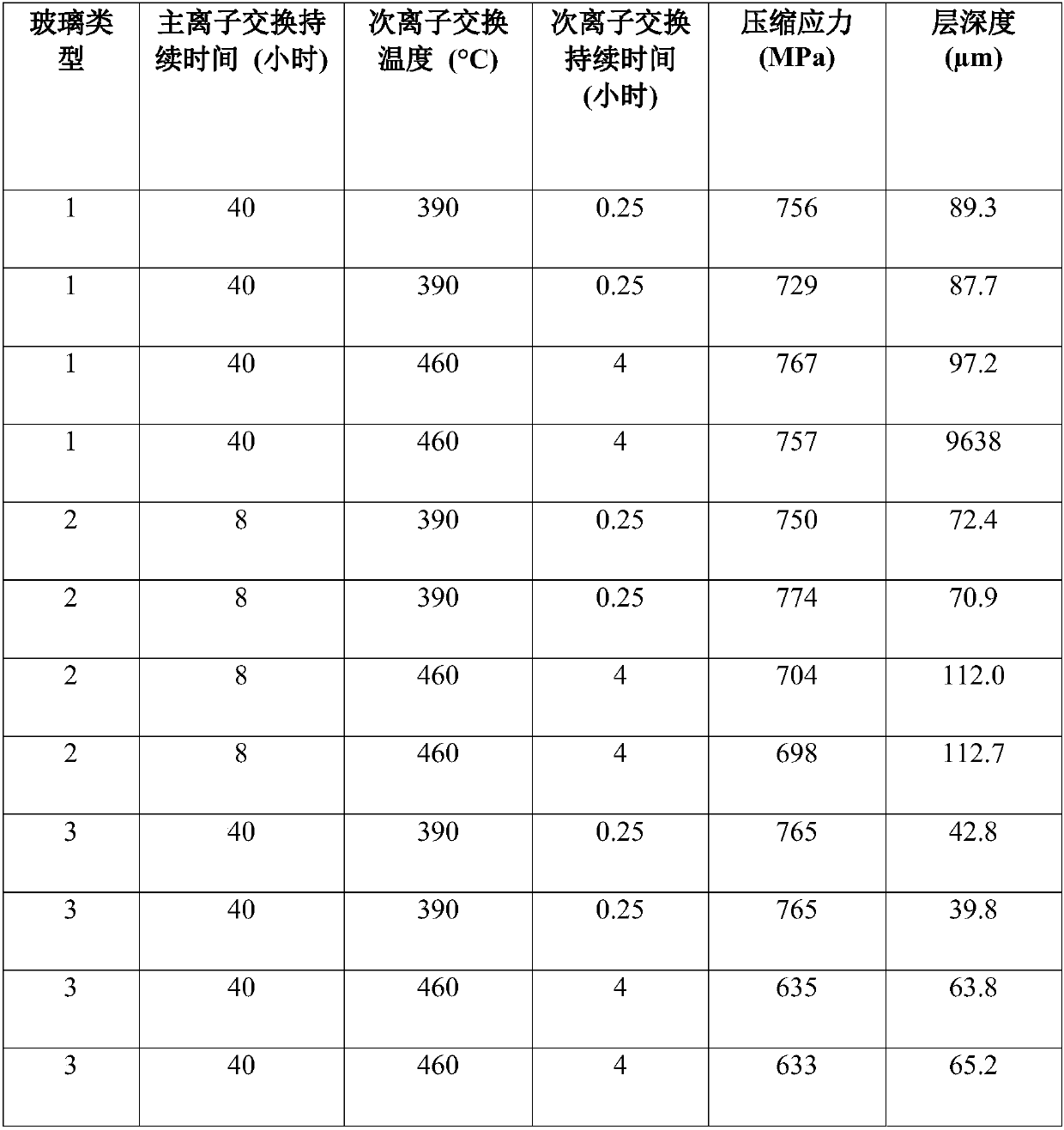

[0045] Eighteen glass sheets were formed according to conventional methods. Form 6 panes of glass from each of the following three glass types: glass 3, Glass 4 and alkali aluminosilicate glass (both manufactured by Corning).

[0046] By mixing 55% by weight of KNO 3 and 45% by weight NaNO 3 To prepare the main ion exchange solution. The mixture was heated to 450°C and 18 glass plates were individually immersed in the primary ion exchange solution for the durations shown in Table 1 below. Subsequently, the glass plate was removed from the primary ion exchange solution and rinsed with water to remove any residual ion exchange solution.

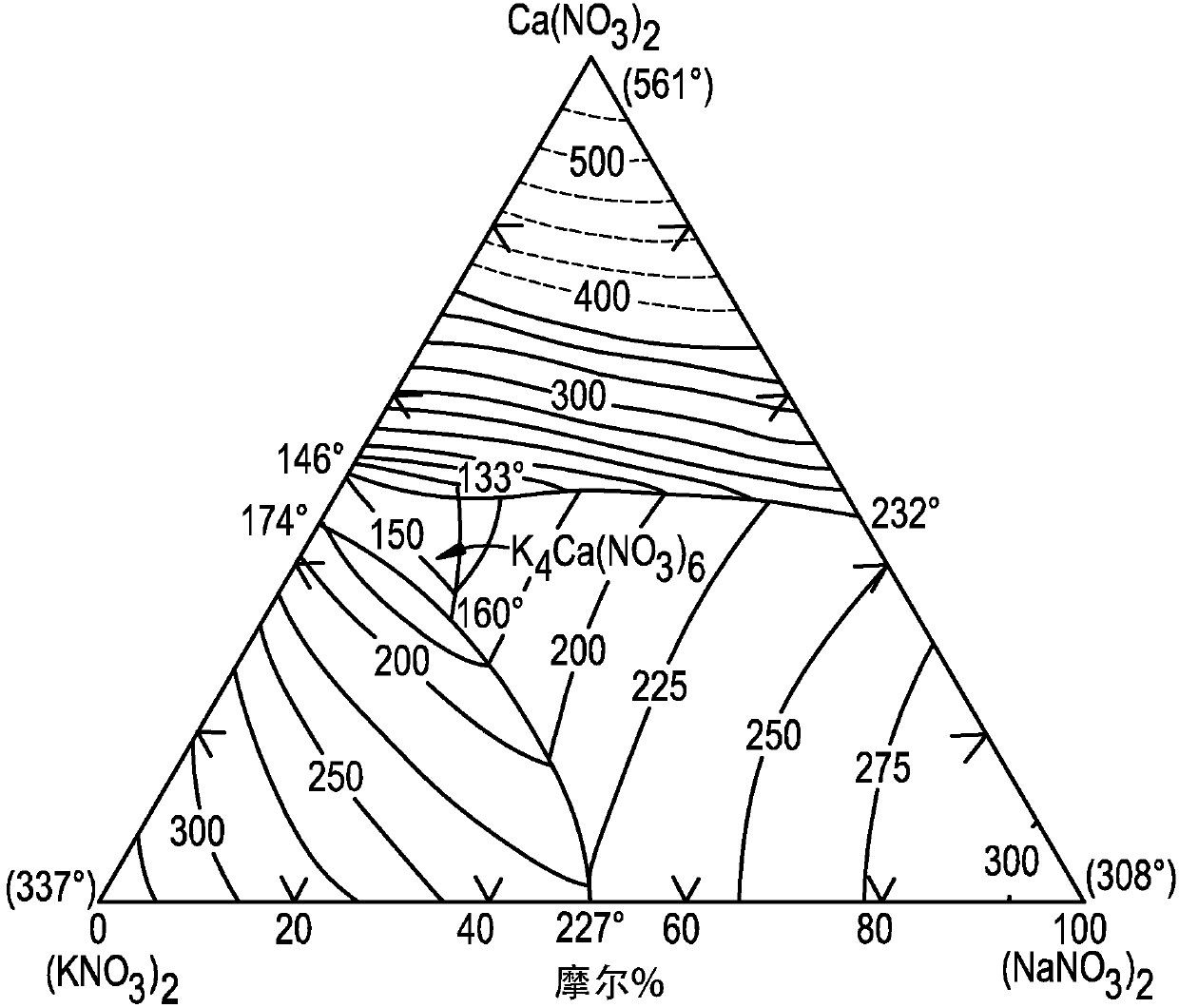

[0047] By mixing 95% by weight of KNO 3 and 5% by weight Ca(NO 3 ) 2 To prepare the secondary ion exchange solution. The mixture was then heated to the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com