A nitrogen-doped carbon material prepared from a porous nitrogen-containing polymer as a precursor and its application

A nitrogen-doped carbon and polymer technology, applied in gas treatment, other chemical processes, separation methods, etc., can solve the problems of high cost and cumbersome preparation process, and achieve the advantages of reducing preparation cost, saving reaction time, and high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

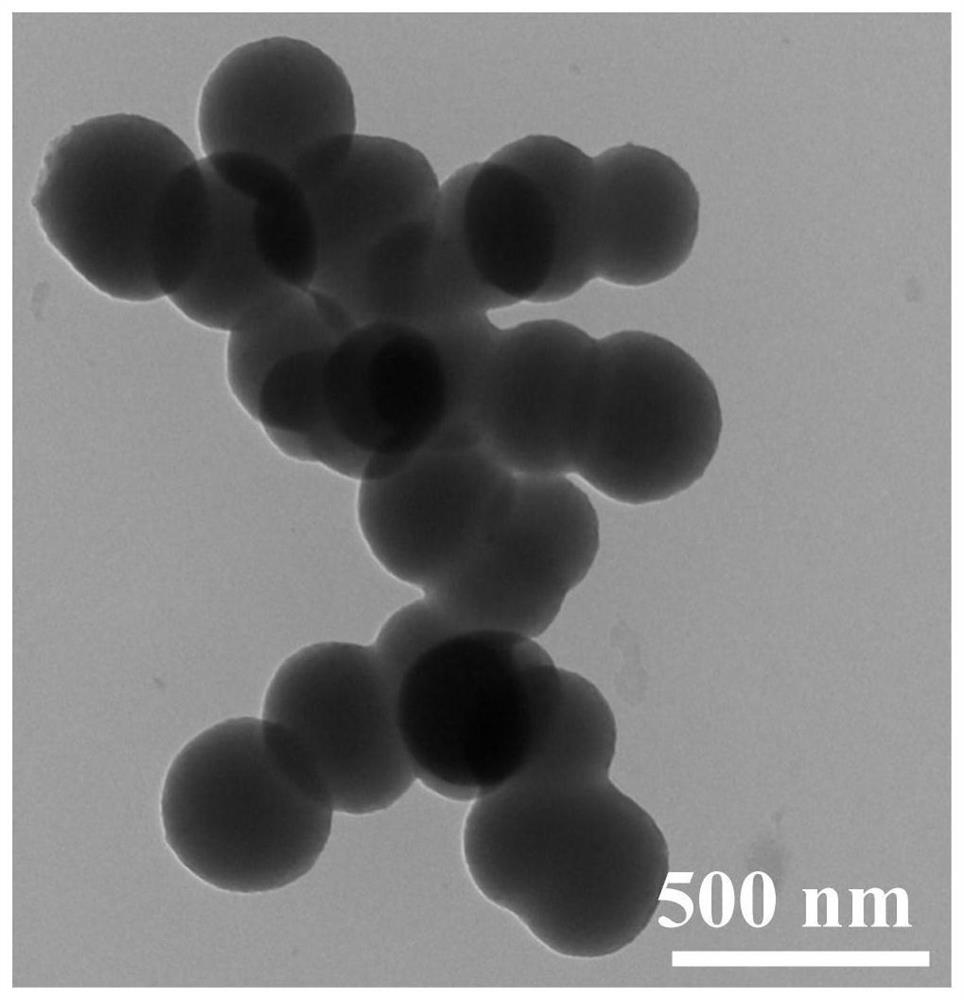

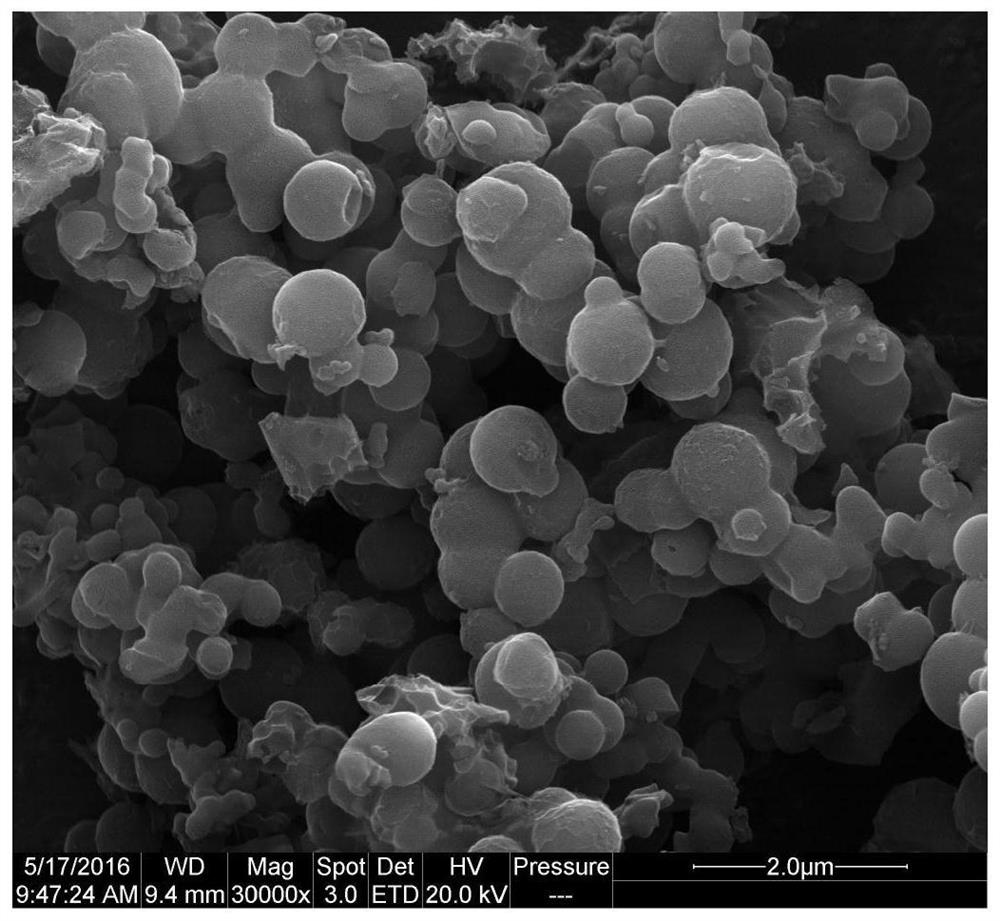

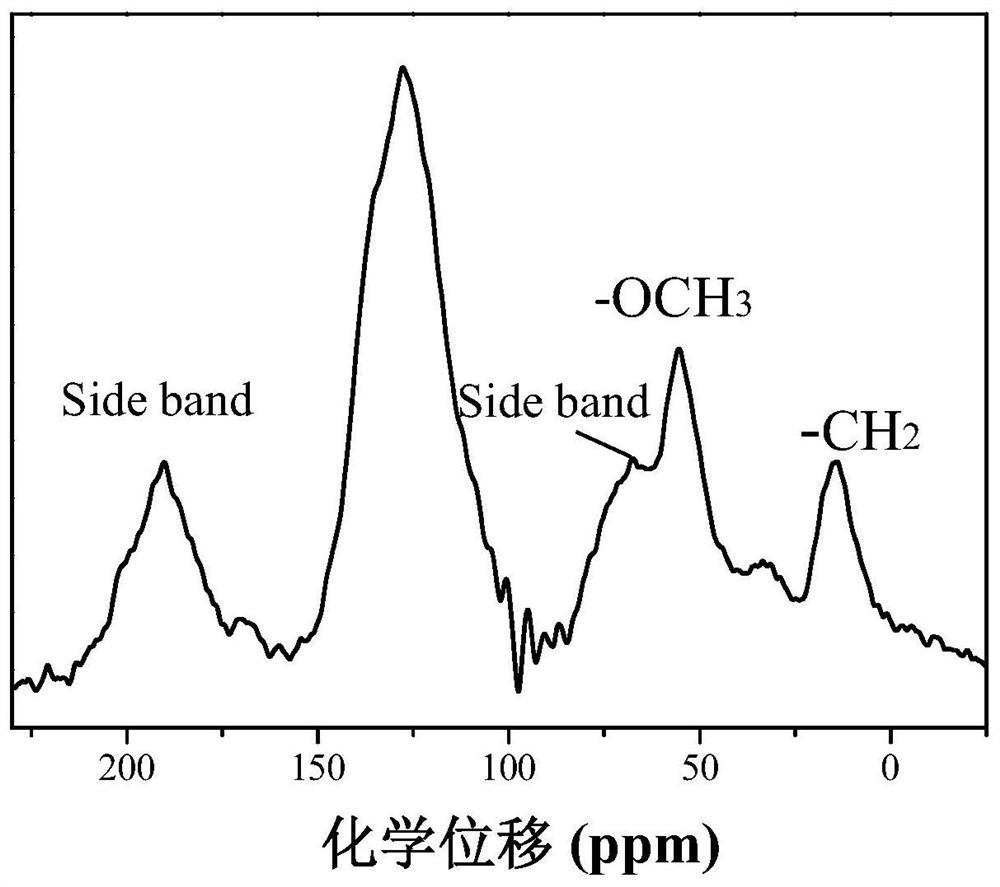

[0036] Example 1: Preparation of nitrogen-doped carbon material NC-1

[0037] Add 20mL 1,2-dichloroethane, 0.391g (3.33mmol) indole monomer into the reaction kettle, stir until the indole is completely dissolved, add about 1.77mL (20mmol) dimethyl formal, stir for 5min, then add 3.25g (20mmol) FeCl 3 , stirred for 5 minutes, put the reaction kettle into a microwave synthesizer for reaction, set the temperature rise program, raised the temperature from room temperature to 45°C, kept it for 20min, and then raised the temperature to 80°C for 1 hour. After the reaction, cool to room temperature, take out the reaction kettle, add a small amount of methanol in the reaction kettle, stir until the polymer solid is uniformly dispersed, filter with suction, and pass the solid through a mixed solution of tetrahydrofuran, methanol, methanol and hydrochloric acid (the volume ratio of methanol and hydrochloric acid 0.5, the concentration of hydrochloric acid is 2mol / L) Soxhlet extraction for...

Embodiment 2

[0040] Example 2: Preparation of nitrogen-doped carbon material NC-2

[0041] This embodiment is basically the same as Embodiment 1, except that the potassium hydroxide that adds 1 / 2th of the porous nitrogen-containing polymer quality, i.e. M 多孔含氮聚合物 :M KOH =2:1. The measured specific surface area is 636m 2 / g, the carbon dioxide adsorption capacity at 25°C and 1 atmospheric pressure is 3.57mmol / g, CO 2 / N 2 Selectivity is 75.

Embodiment 3

[0042] Example 3: Preparation of nitrogen-doped carbon material NC-3

[0043] This embodiment is basically the same as Example 1, except that the potassium hydroxide that adds a quarter of the porous nitrogen-containing polymer quality, i.e. M 多孔含氮聚合物 :M KOH =4:1. The measured specific surface area is 326m 2 / g, the carbon dioxide adsorption capacity at 25°C and 1 atmospheric pressure is 2.58mmol / g, CO 2 / N 2 Selectivity is 101.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| carbon dioxide adsorption capacity | aaaaa | aaaaa |

| carbon dioxide adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com