Grass cutting hob blade grinding device and grinding method thereof

A hob and grinding technology, which is applied in the field of cutting hob blade grinding devices, can solve the problems of narrow welding space, low welding efficiency, poor welding seam quality, etc., and achieves simple operation, improved welding efficiency and good quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

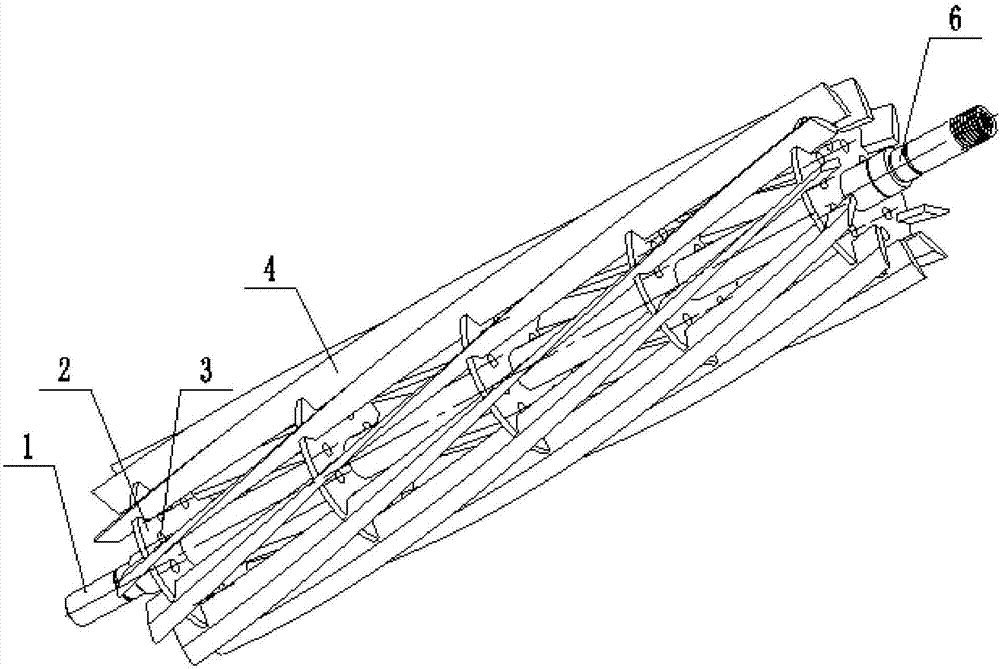

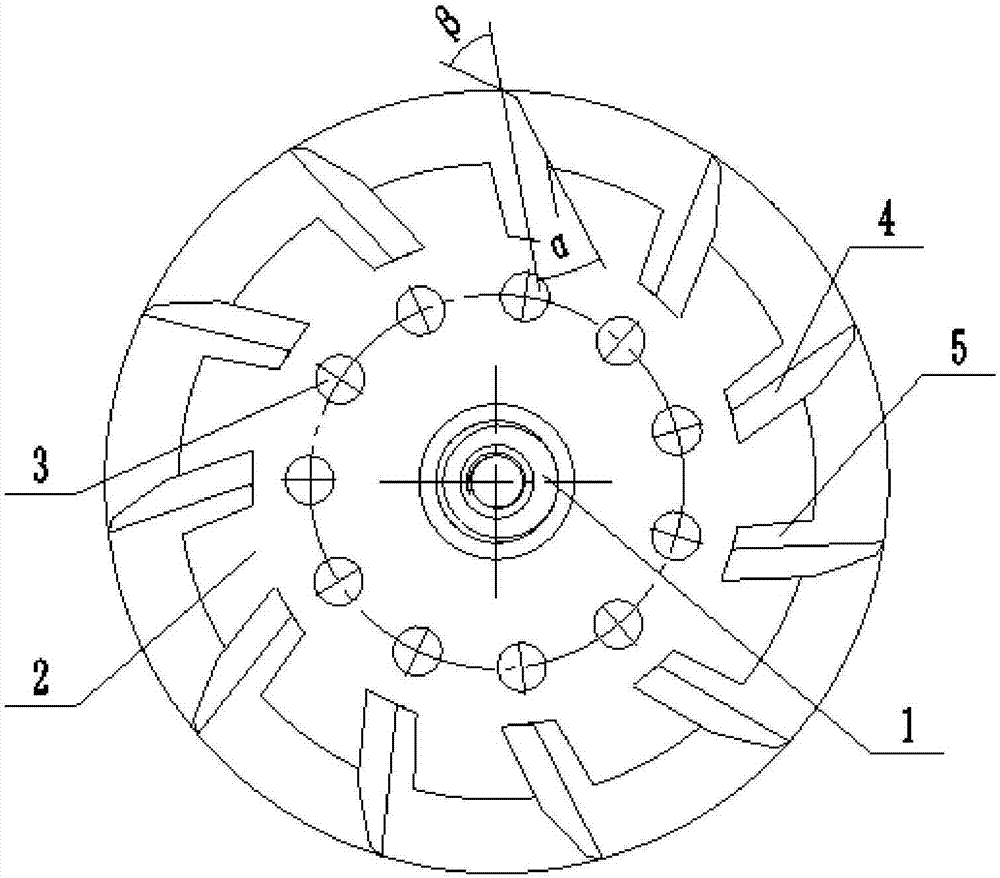

[0053] like figure 1 and figure 2 Shown is the structure of the mowing hob, which mainly includes a hob shaft 1, a cutter head 2 and a hob blade 4; among them, there are multiple cutter heads 2 welded at equal intervals along the axial direction of the hob shaft 1, and the cutter head There are slots 5 along the circumferential direction on the 2, and the spiral hob blades 4 are inserted into these slots 5 in sequence for positioning, and then welded and fixed, and corresponding to the number of slots 5, generally a circle of uniform slots in the circumferential direction is set on the cutter head 2. The positioning hole 3 of the cloth is used for adjusting the dynamic balance of its rotation after hob processing. In addition, there is a bearing segment 6 at both ends of the hob shaft 1, which is used to install the bearings, so that the hob is installed on the lawn machine when in use. In addition, the outer surface of the hob blade 4 has a blade, and the blade is two slop...

Embodiment 2

[0060] This embodiment provides a welding method for a grass mowing hob. The robot welding device for the grass mowing hob in Embodiment 1 is used in cooperation with a welding robot to weld the hob blade 4 to the cutter head 2 . In this embodiment, there are 5 cutterheads 2 and 10 hob blades 4. Generally, the back angle α=16° and the edge angle β=53°. The specific operation steps of welding are as follows:

[0061] ①Install the hob 4 into the slot 5 on the cutter head 2 in sequence, and fix it from both ends and / or the middle of the hob 4 through a packing steel belt or hoop. Here, the hoop is selected from the hob 4 Fixed at both ends;

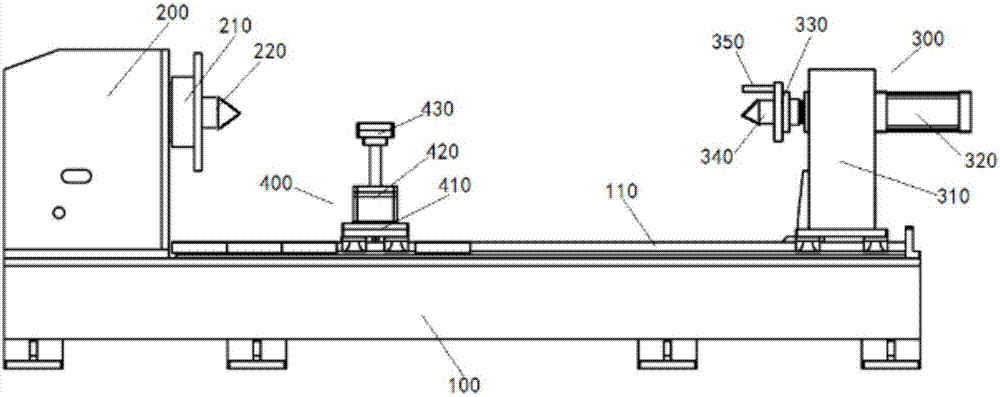

[0062] ②Place the hob on the supporting plate 430 of the material supporting mechanism 400, and the supporting cylinder 420 works to adjust the height of the supporting plate 430, so that the hob shaft 1 of the hob is coaxial with the first thimble 220, and the first thimble 220 pushes into the thimble hole at one end of the hob shaft 1;

...

Embodiment 3

[0068] This embodiment provides a grinding method of a grass mowing hob. The hob welded in Embodiment 1 is ground to grind the cutting edge of the hob blade 4 . And the hob blade 4 itself is helical, and its blade is also helical, and the grinding along the helical line cannot be accomplished by present common grinders, and is also the difficult point of hob grinding. The utility model relates to a blade grinding device of a mowing hob, which is used to grind the blade of a hob 4.

[0069] like Image 6 and Figure 7As shown, the blade grinding device of the mowing hob in this embodiment includes a grinding wheel mechanism, and the grinding wheel mechanism includes a fixed support assembly 500 , a movable support assembly 600 and a grinding wheel assembly 700 . Wherein, the fixed support assembly 500 includes a fixed support 510 and a first support plate 520 installed on the fixed support 510, the first support plate 520 has a first bearing hole; Support 610, second support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap