Clamping device for machining of four-axis turbocharging casing

A turbocharging and clamping device technology, which is applied in the direction of clamping devices, positioning devices, metal processing equipment, etc., can solve the problems of high processing cost, complex blade profiling cavity structure, and complex structure, so as to reduce processing costs , light weight, easy clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described now in conjunction with accompanying drawing.

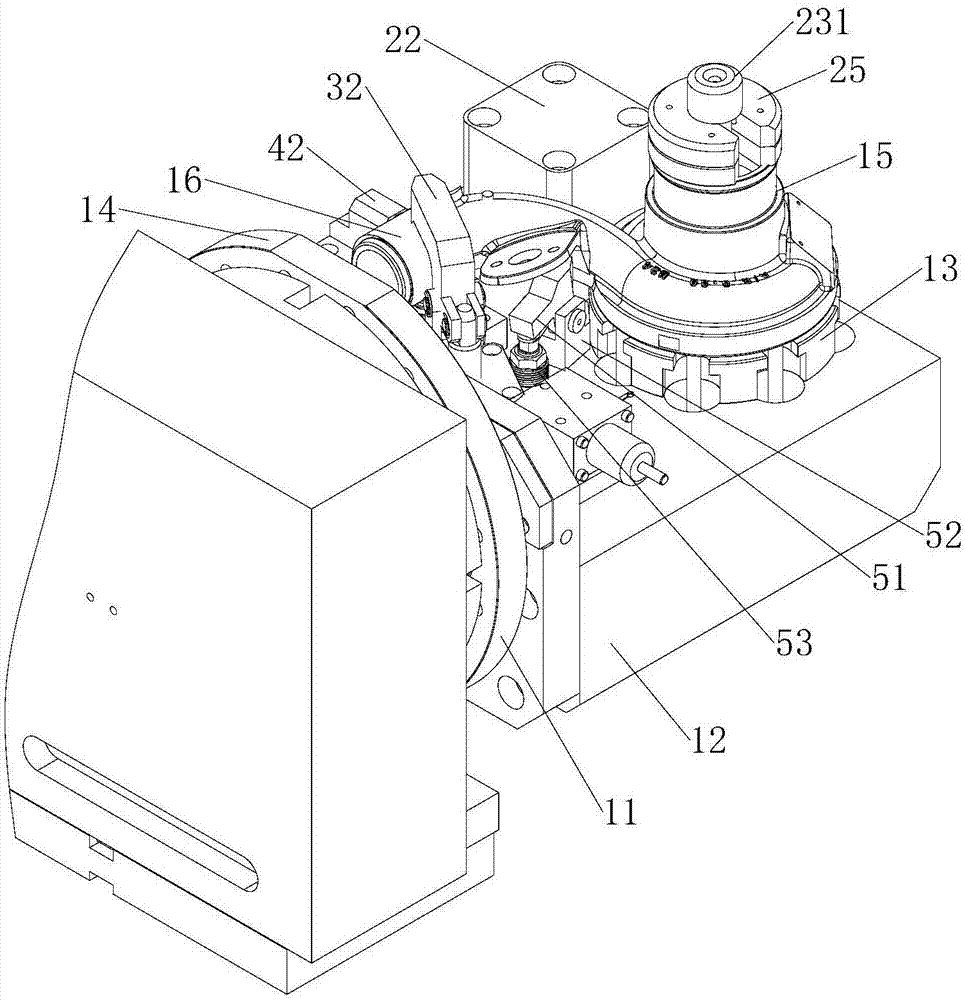

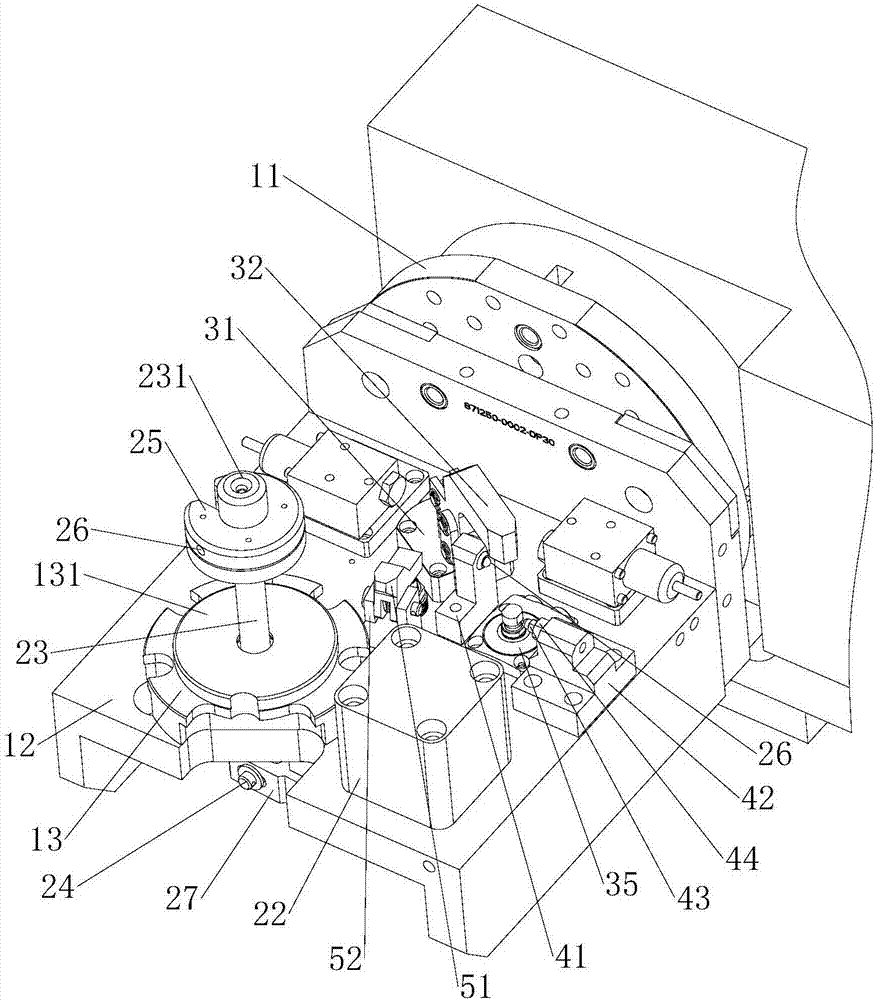

[0035] Such as figure 1 and figure 2As shown, a clamping device for four-axis turbocharging shell processing includes a connecting plate 11, a base 12, a positioning seat 13, a housing clamping device and an air outlet pipe clamping device; the connecting plate 11 is fixed on the clamp of the indexing plate On the plate 14, the connecting plate 11 is connected with the base 12, the base 12 is equipped with a positioning seat 13, the top of the positioning seat 13 is provided with a boss 131, the boss 131 is stuck on the intake pipe 15 of the turbocharger shell, and the shell is clamped The device compresses the air intake pipe 15 of the turbocharger shell on the positioning seat 13, and the air outlet pipe clamping device fixes the air outlet pipe 16 of the turbocharger shell on the base 12.

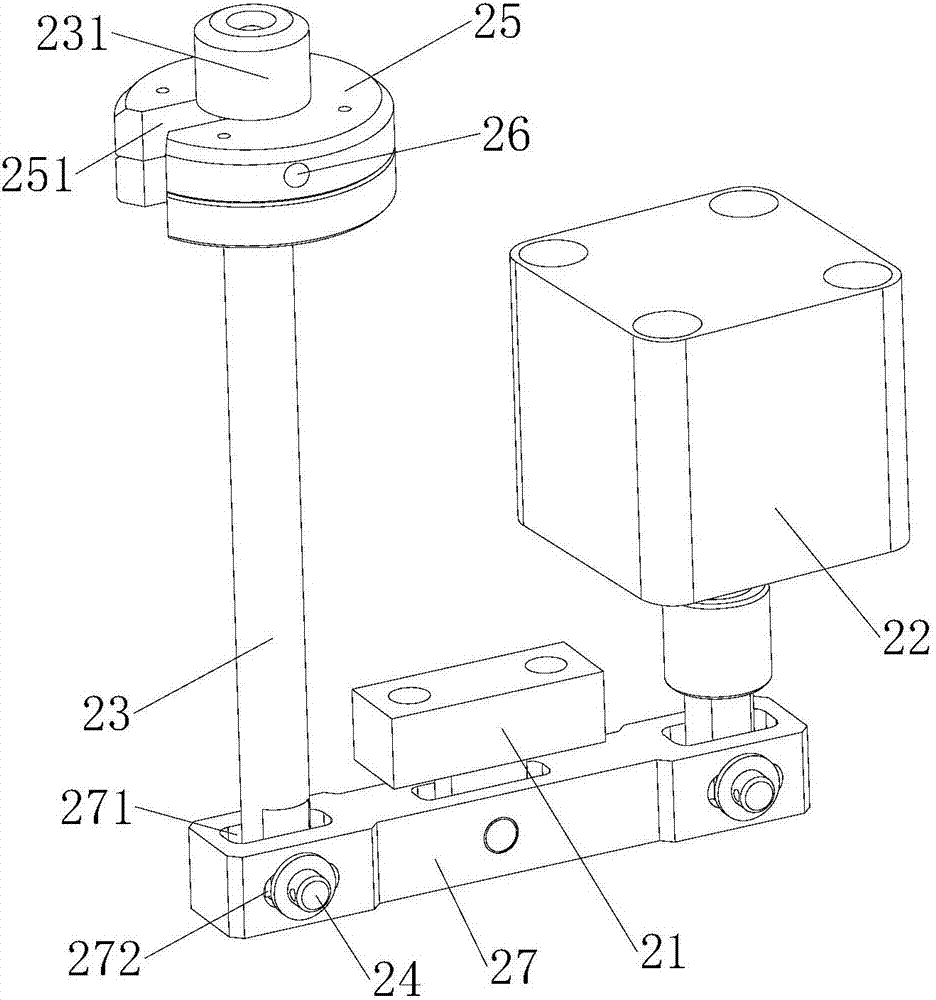

[0036] Such as image 3 As shown, the housing clamping device includes a lever ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap