Flat car for pipe piece prefabricated plant

A technology of prefabrication plant and flatbed truck, which is applied in the direction of freight vehicles, motor vehicles, goods transport vehicles, etc., can solve the extrusion deformation of the segment, the segment is easy to slip off the flatbed, and the clamping and fixing effect of the segment is not ideal. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

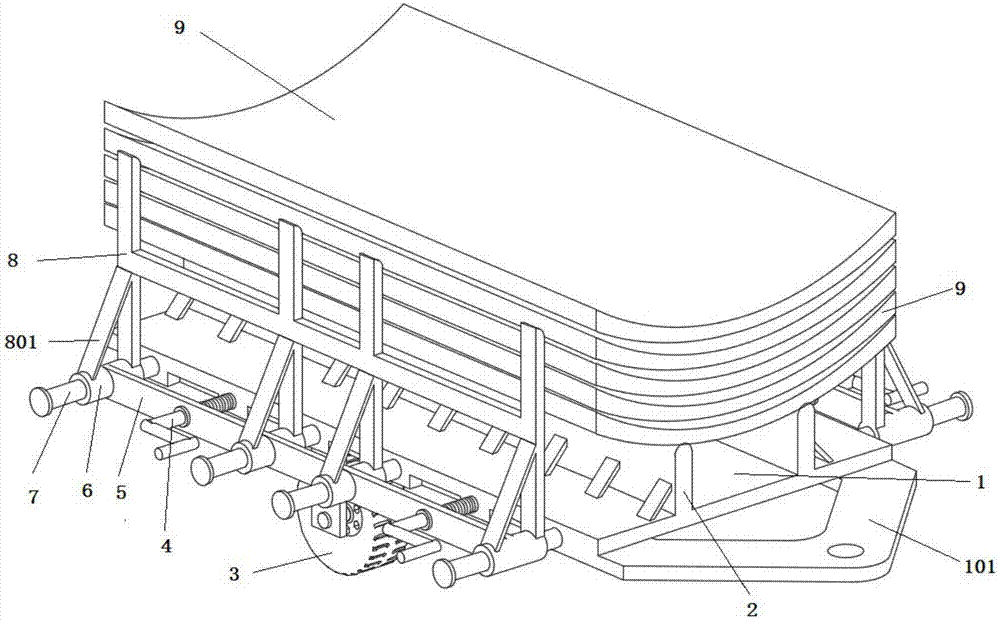

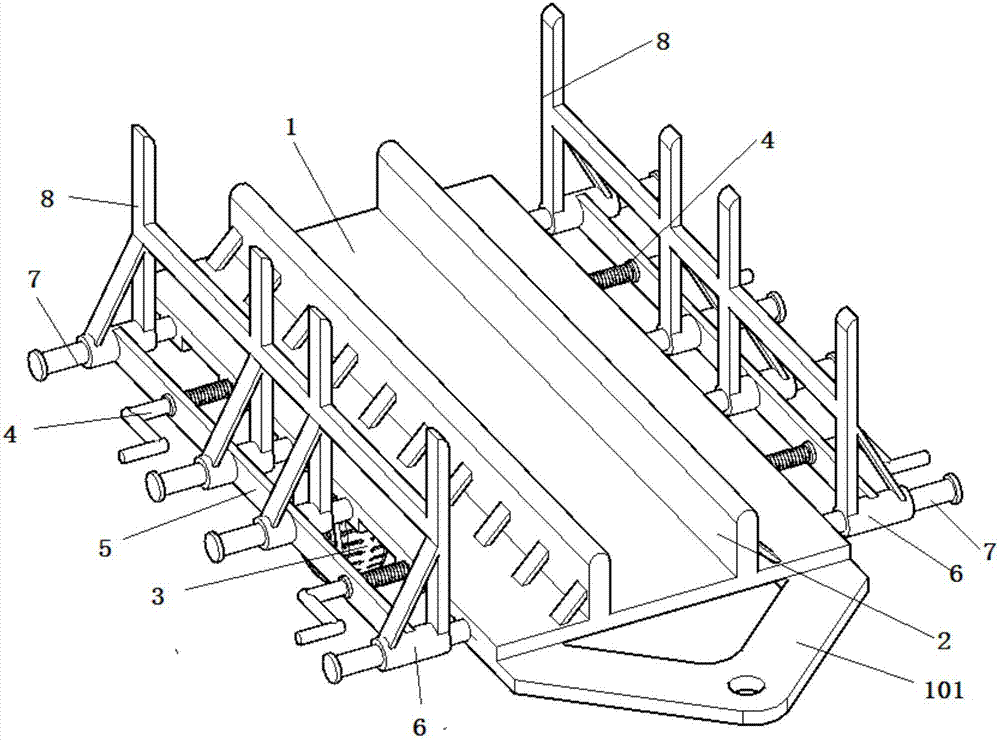

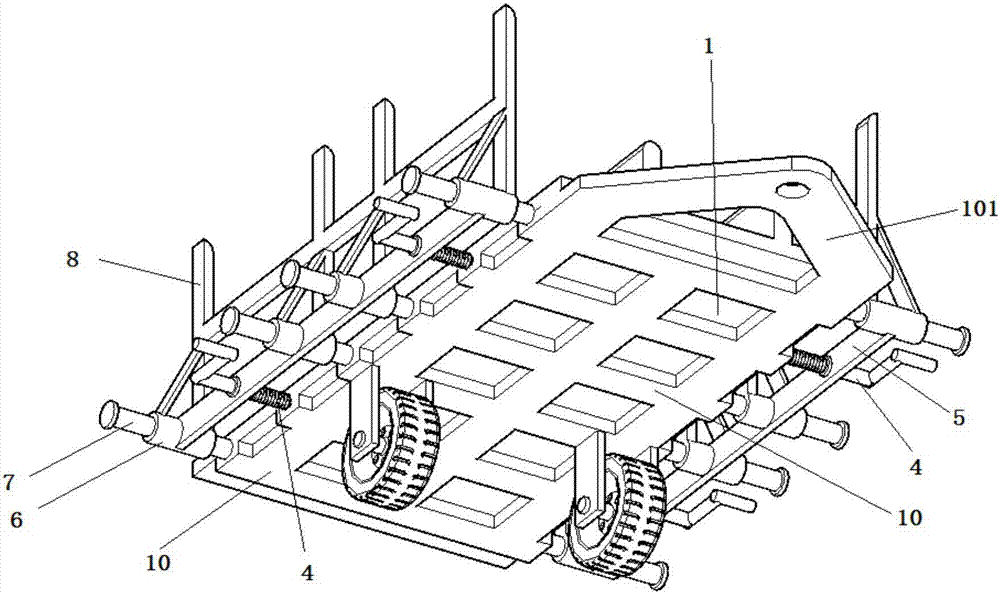

[0024] as attached figure 1 to attach Figure 5 Shown:

[0025] The present invention provides a flatbed car for segment prefabrication factory, which includes a base plate 1, a traction plate 101, a support plate 2, wheels 3, a handle rotation screw 4, a connecting horizontal plate 5, a sliding sleeve 6, and a supporting sliding shaft 7. The support slant plate 801, the segment 9, the reinforcement frame 10, the middle part of the top end surface of the base plate 1 is symmetrically welded and supported by two support plates 2, and the bottom end surface of the base plate 1 is welded and fixed with a reinforcement frame 10, here The reinforced frame 10 is formed by welding six horizontal braces and three vertical braces perpendicular to each other; the bottom of the reinforced frame 10 is symmetrically hung and welded with two sets of roller support plates, and the two wheels 3 are respectively rotated and installed on two sides. In the middle of the group roller support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com