A composite modification method of high-entropy alloy extruded pier

A high-entropy alloy and modification technology, applied in the field of plastic modification, can solve the problems of high-entropy alloy lattice distortion, easy formation of cracks, hindering the application of plastic processing forging modification process, etc. The effect of promoting mass use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

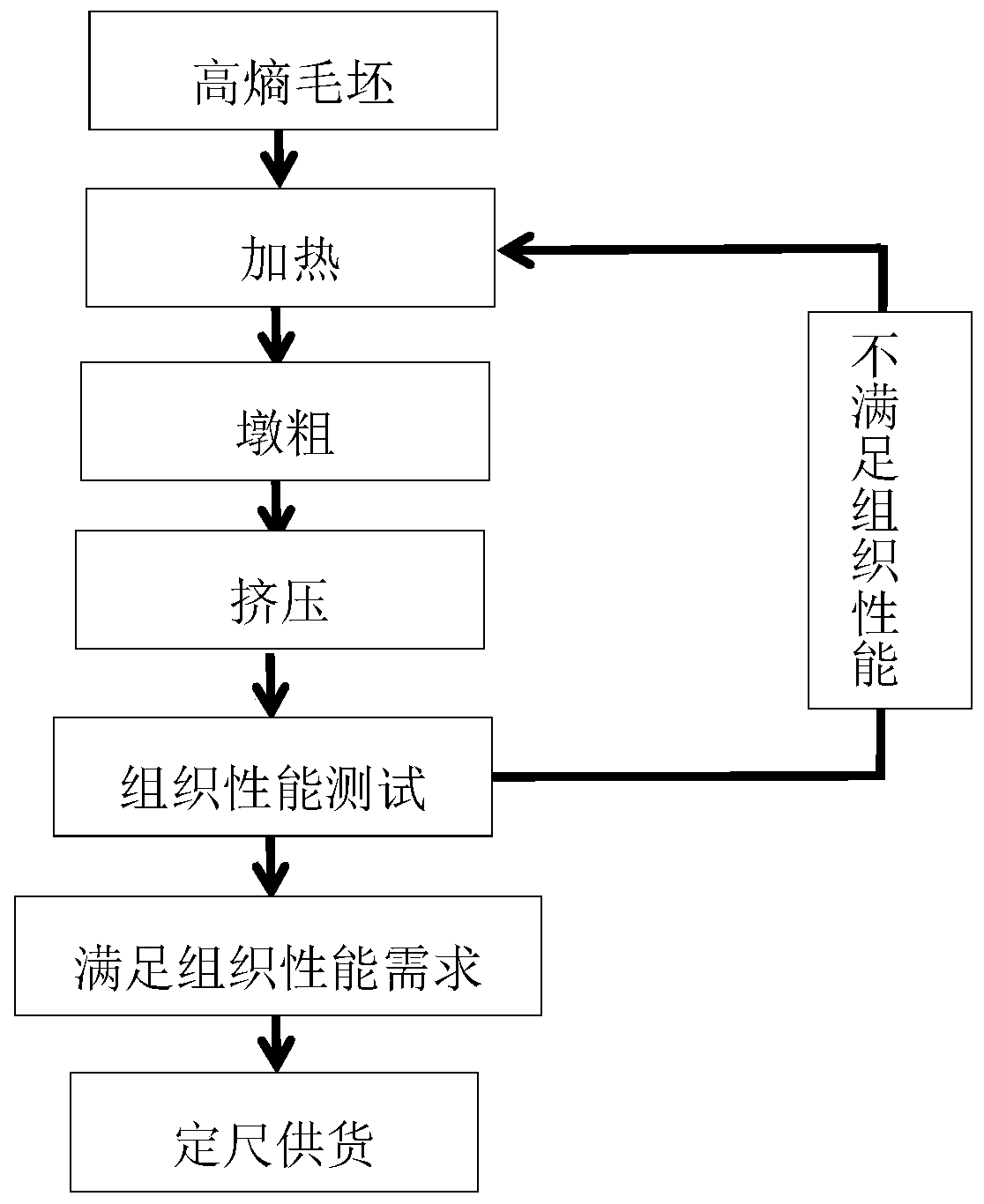

Method used

Image

Examples

Embodiment Construction

[0019] Taking AlCrFeNiCuMu as an example, this embodiment is an AlCrFeNiCuMu with uniform structure and significantly improved mechanical properties prepared by pier extrusion composite technology. 0.5 The method for the high-entropy alloy ingot billet is specifically completed according to the following steps:

[0020] (1) Prepare high entropy alloy: AlCrFeNiCuMu 0.5 Ingot: the selected composition is AlCrFeNiCuMu 0.5 In the ingot of the high-entropy alloy, the molar ratios of the five elements are Al:Cr:Fe:Ni:Cu:Mu=1:1:1:1:1:0.5.

[0021] (2) Homogenization heat treatment: AlCrFeNiCuMu selected in step (1) 0.5 The high-entropy alloy ingot is subjected to homogenization heat treatment. The temperature of the homogenization heat treatment is 1000°C-1100°C, and then the heat preservation treatment is carried out according to the thickness of the ingot 0.8-1min / mm. The heat preservation time of the homogenization heat treatment is 12h-100h, and the internal structure is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com