Touch type baffling feeding door device for combustion boiler

A technology of feeding door and boiler, which is applied in the special configuration of fuel supply, door of combustion chamber, combustion chamber, etc., can solve the problems of increasing the nitrogen oxide content of the boiler, outward burning of the boiler flame, and long feeding time. , to achieve the effect of simple structure, reducing the probability of burning, and high degree of automation of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described.

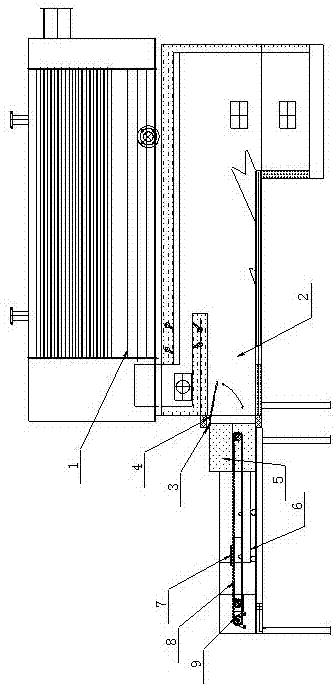

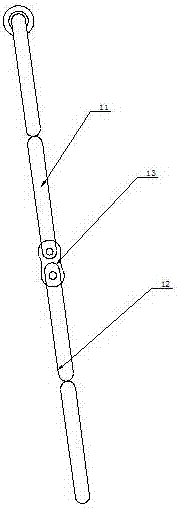

[0016] see as figure 1 , figure 2 As shown, this specific embodiment adopts the following technical scheme: it includes a combustion boiler 1, a furnace preheating bin 2, a revolving door shaft 3, a barrier door 4, a straw fuel block 5, a pushing trolley 6, a connecting clamp 7, a transmission Chain 8, pusher reducer 9; the lower end of the combustion boiler 1 is provided with a furnace preheating bin 2, and the left upper end of the furnace preheating bin 2 is connected with a partition door 4 through a rotating door shaft 3, and the partition The left side of the gate 4 is provided with a straw fuel block 5, and the left side of the straw fuel block 5 is connected with a pushing trolley 6, and the pushing trolley 6 is connected with a transmission chain 8 on one side through a connecting clamp 7, and the transmission The chain 8 forms a circle of rotating orbit throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com