Clamping device of Leeb hardness tester for detecting hardness of pipeline

A Leeb hardness and clamping device technology, which is applied in the field of Leeb hardness tester clamping devices for pipe hardness testing, can solve problems such as consumption of elastic potential energy, overall elastic deformation, and low measurement results, so as to increase rigidity and prevent inaccurate Adherence, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

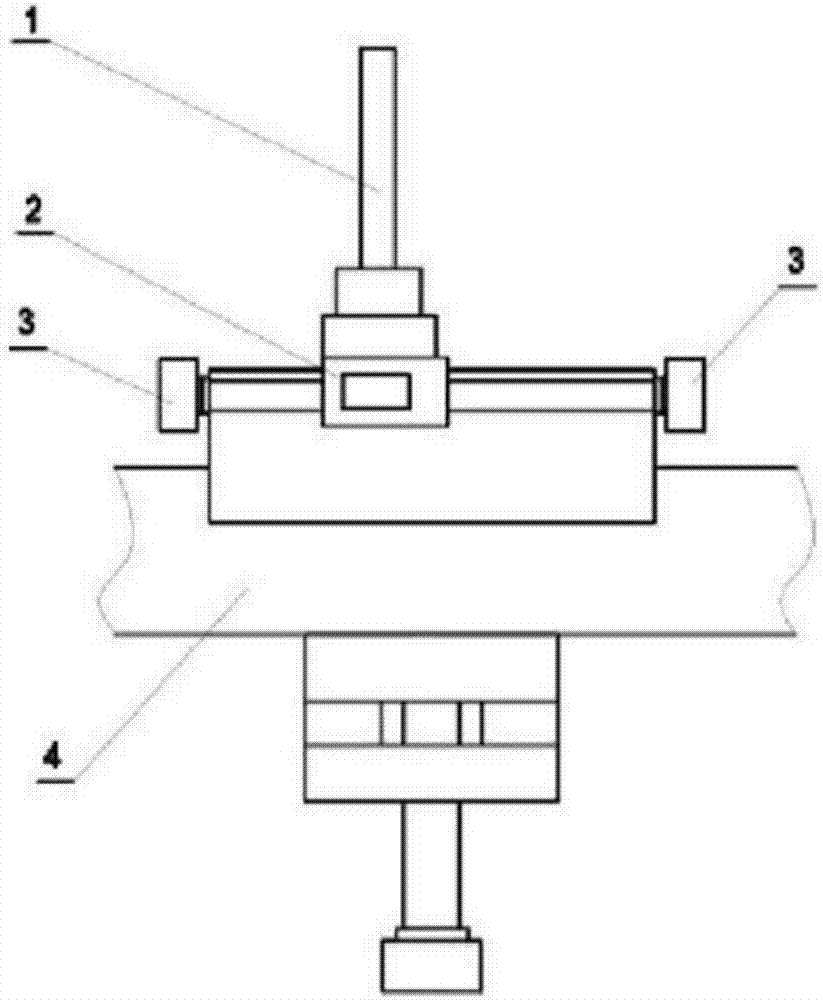

[0021] A Leeb hardness tester clamping device for pipe hardness testing, comprising a pipe clamping and fixing part, a Leeb hardness tester fixing base, and a hardness tester sliding track block along the pipeline axis;

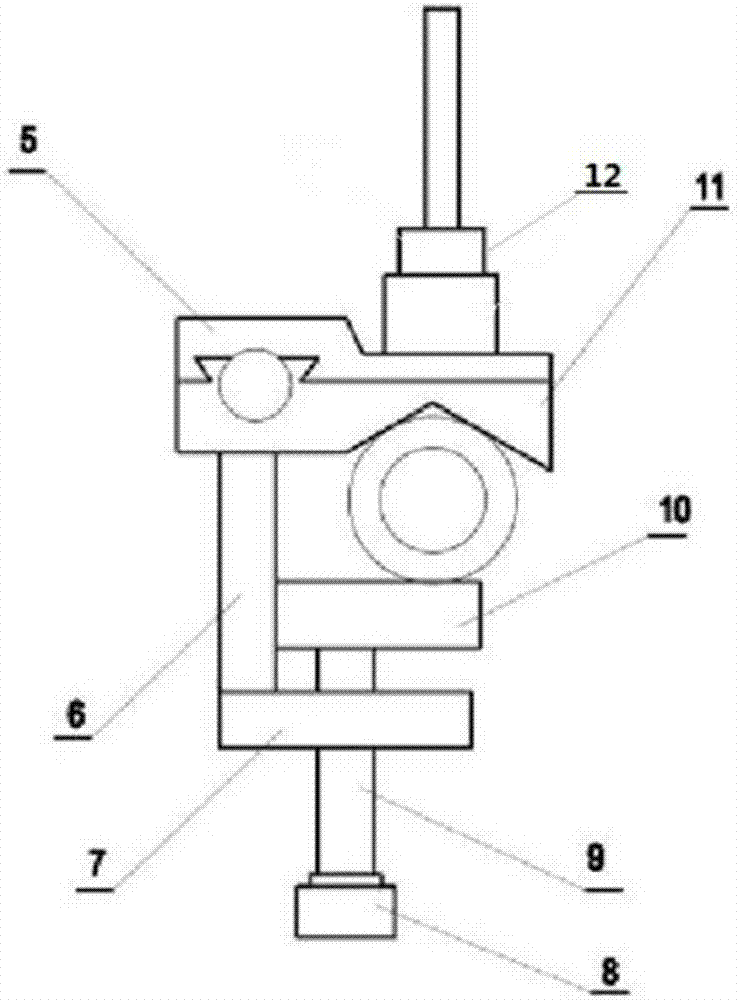

[0022] The clamping and fixing part of the pipeline includes a clamp body 6, a fixed baffle 7 on the lower side, a screw 9 passing through the fixed baffle 7, and a fixed V-shaped jaw 11 on the upper side, and the outer end of the screw 9 is a clip. Tightening wheel 8, the inner end is a movable clamping block 10, the position of the movable clamping block 10 is adjusted by rotating the clamping wheel 8, so as to tightly clamp the pipe;

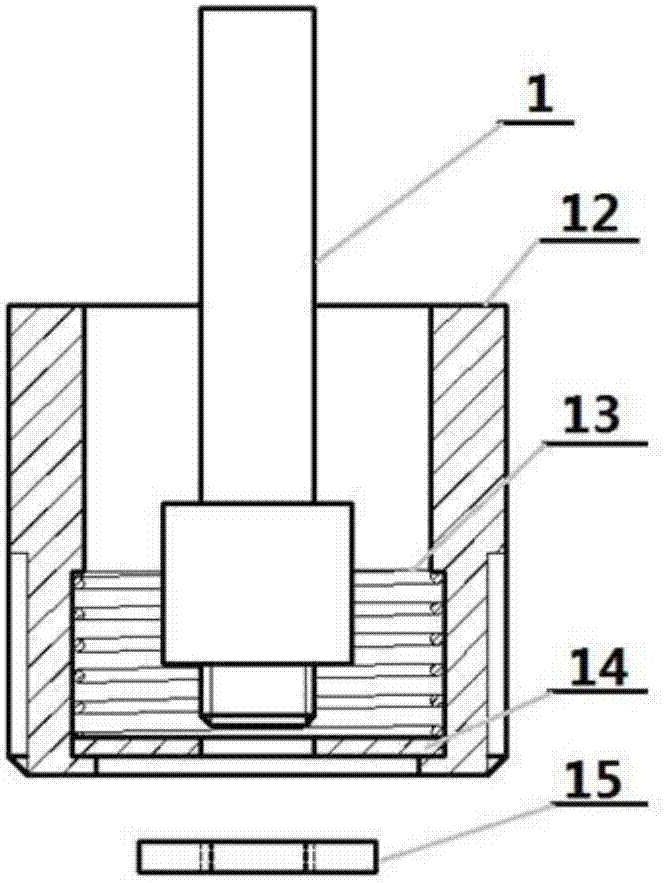

[0023] The fixed base 12 of the Leeb hardness tester is tubular, and a gasket 14 is provided at the bottom thereof. The hole diameter of the spacer 14 is larger than the outer diameter of the conduit thread of the impact bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com