Power facility test system based on breakdown measurement device

A technology of power facilities and testing systems, which is applied in the field of testing systems, can solve problems such as huge workload, and achieve the effect of rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

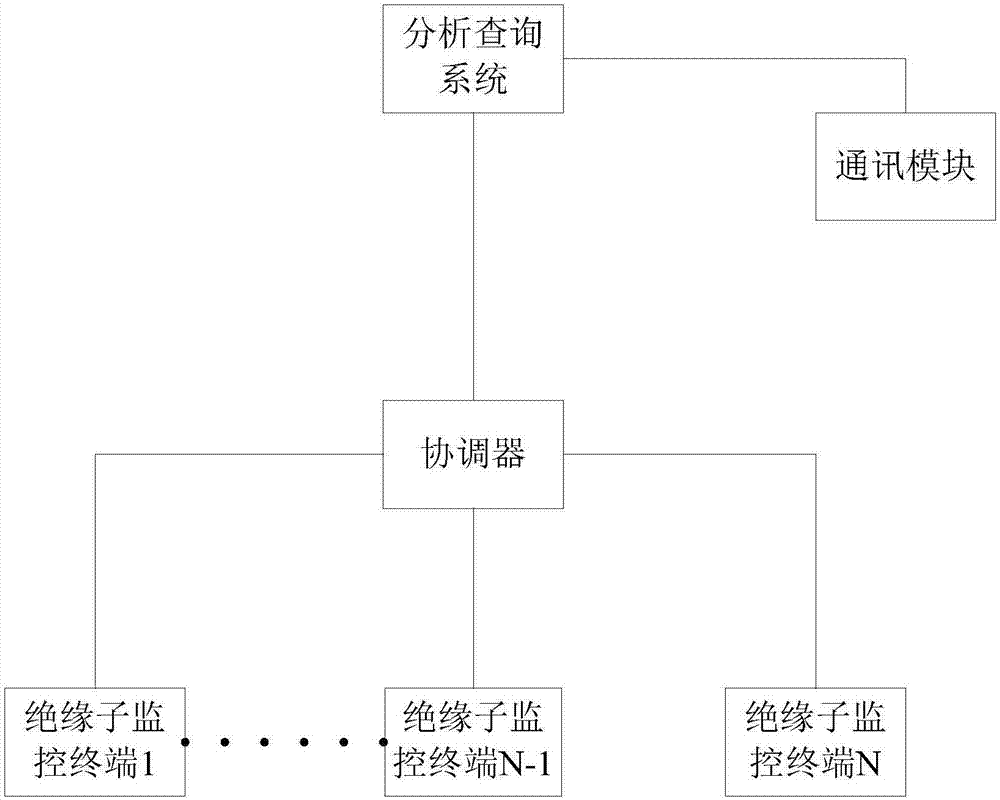

[0015] like figure 1 As shown, the present invention is based on a breakdown measurement device-based power installation test system, and the breakdown measurement device-based power installation test system includes a leakage current sensor installed in each insulator base, and the secondary side current of the leakage current sensor passes through The current loop is led out to each insulator monitoring terminal, and each insulator monitoring terminal is connected to the coordinator through a wireless transmission module, and the data output part of the coordinator is connected to an analysis and query system. GSM for network transmission. The secondary side current of the sensor can be drawn to the insulator monitoring terminal through the current loop, and then transmitted to the coordinator. After the coordinator finds a fault, it enters the analysis and query system, and the leakage current is measured through the leakage current transformer and related circuits to deter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap