Electromagnetic valve combination-based cooling wind tunnel temperature control method

A temperature control method and solenoid valve technology, which is applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, testing of machine/structural components, etc., can solve the problem of combining the number of solenoid valves in cooling wind tunnels Waiting for questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

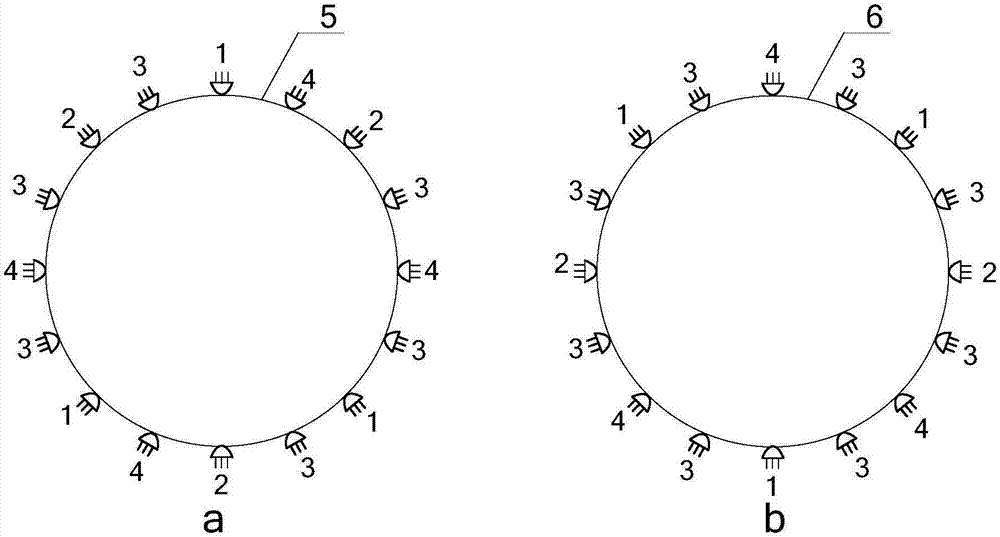

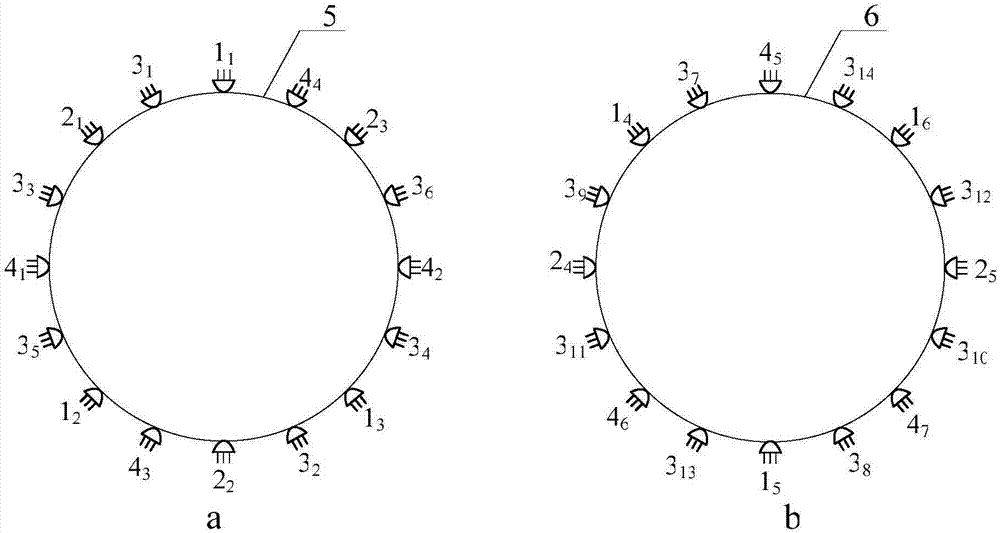

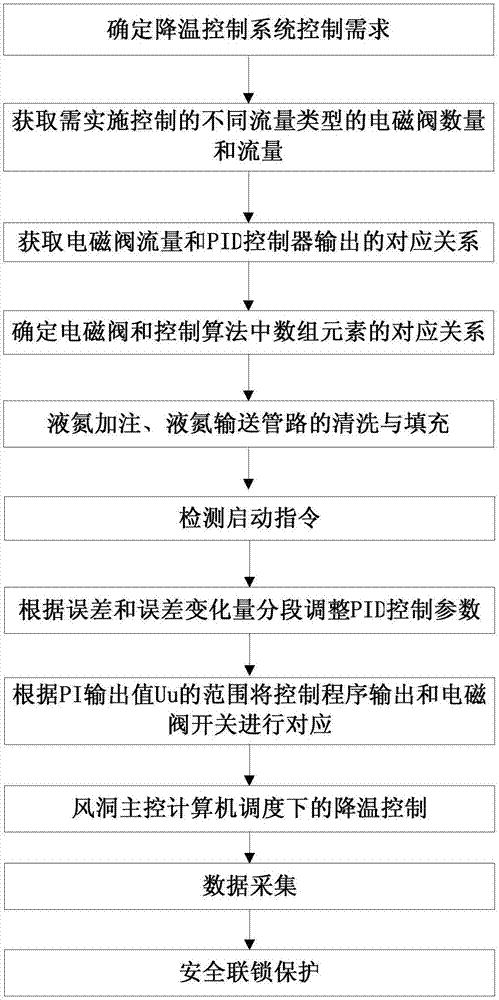

[0052] This embodiment is a cooling wind tunnel temperature control method based on a combination of solenoid valves. The cooling control system implements cooling by pushing and injecting liquid nitrogen, mainly based on control figure 1 The switch combination of the solenoid valve on the center liquid ring realizes the control of the injection flow, and then realizes the precise control of the temperature. figure 1 It is a side view of the wind tunnel along the air flow direction. The liquid nitrogen injection solenoid valve and nozzle are installed on the liquid collection ring, which is also used for liquid nitrogen filling. The solenoid valve group on the liquid collection ring includes two parts, which are divided into the upstream solenoid valve group and the downstream solenoid valve group. Solenoid valve group. figure 1 The upstream solenoid valve group in a is located between the compressor and the heat exchanger, and is specifically installed near the compressor sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com