Rapid brake device for three-phase asynchronous motor

A three-phase asynchronous and braking device technology, applied in the direction of motor generator control, motor/generator/inverter limiter, electrical components, etc., can solve the problem of untimely brake braking, troublesome use, troublesome users, etc. problems, achieve the effect of easy replacement and installation, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following specific descriptions of the present invention are given by the examples, which are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

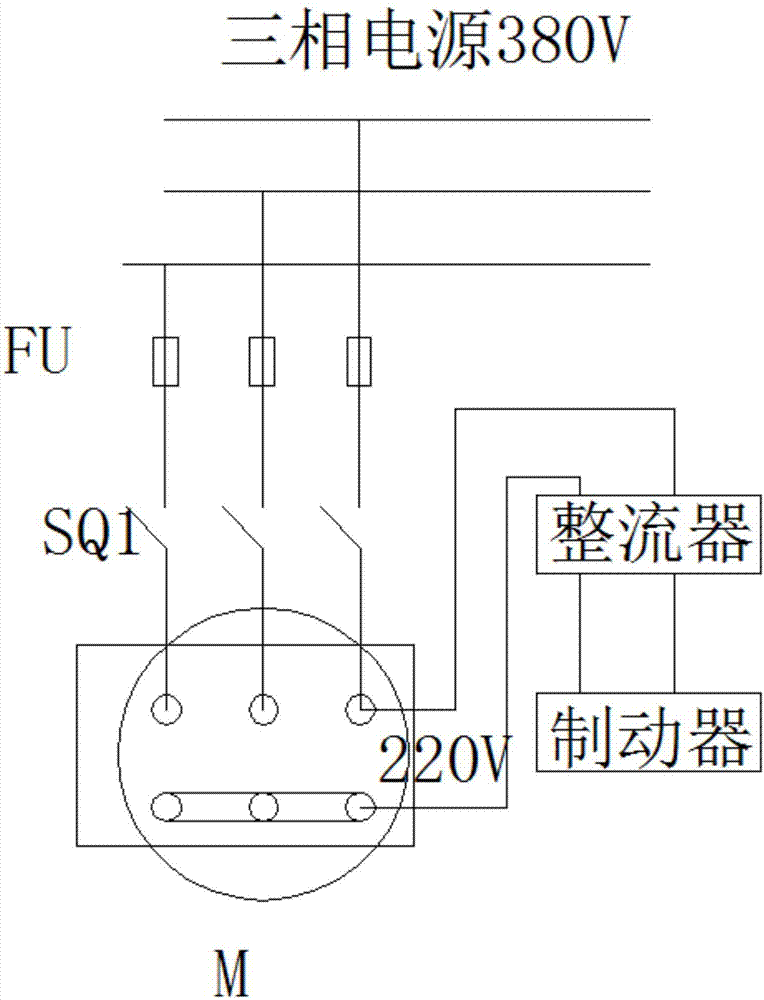

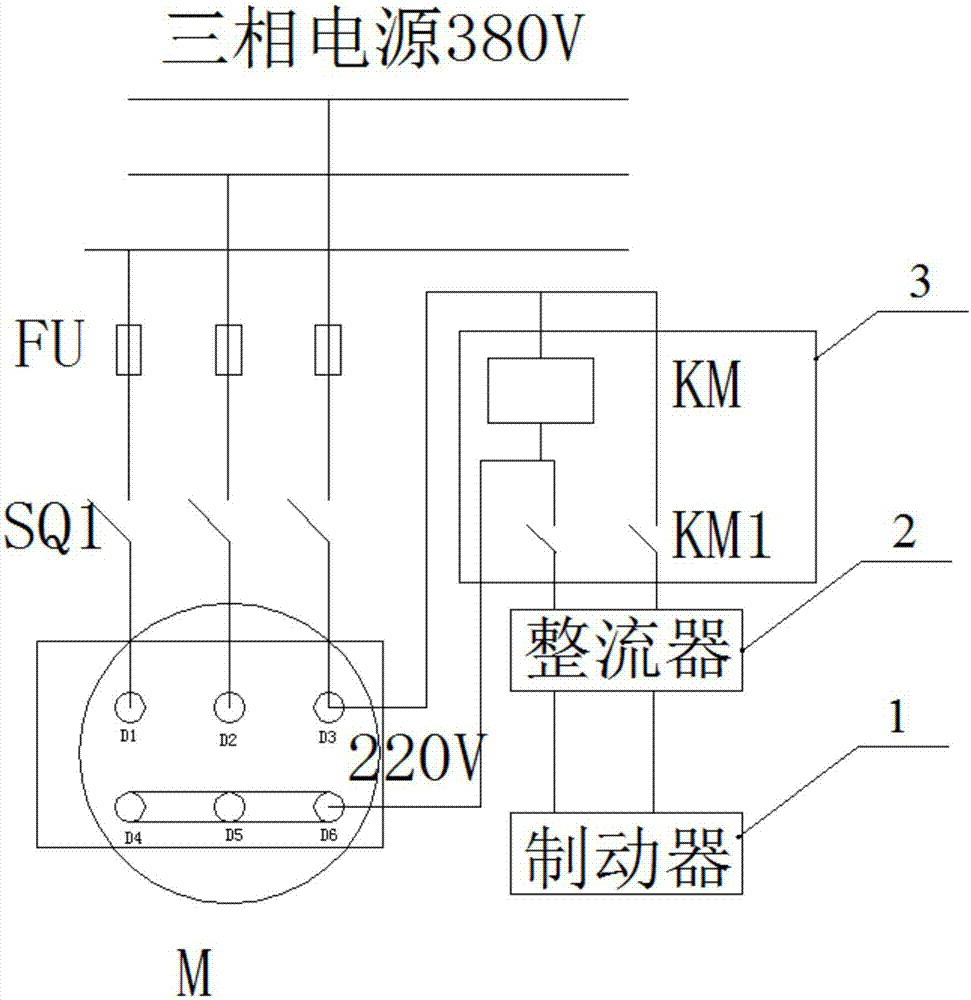

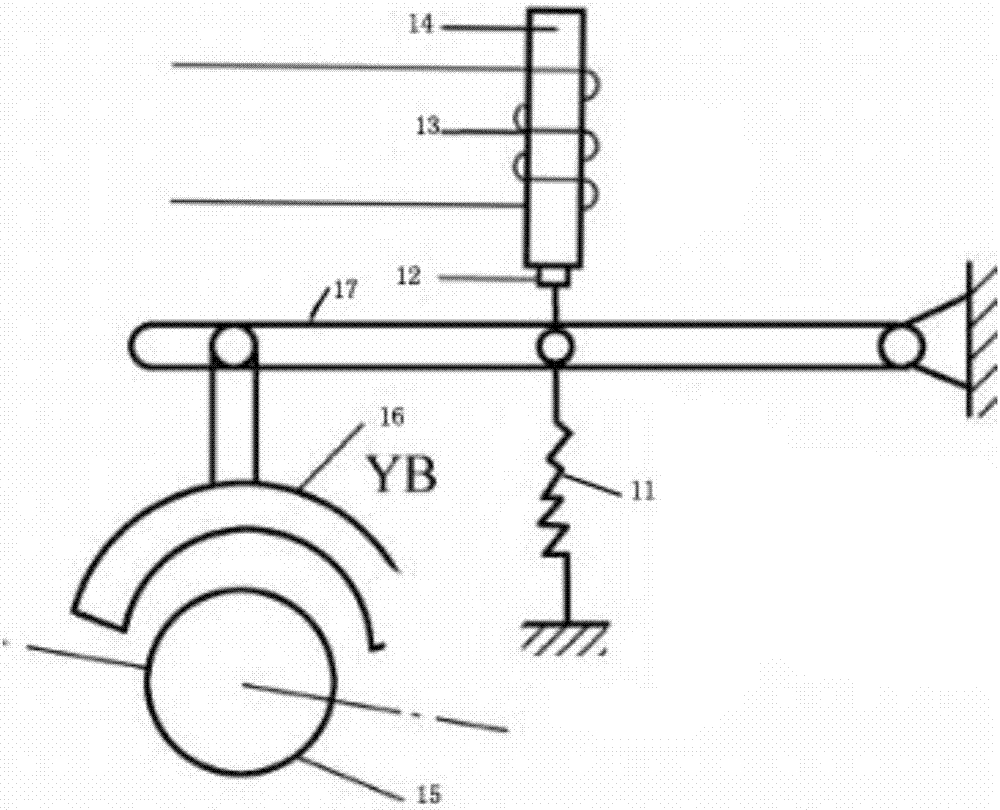

[0018] like Figure 2-3 The specific embodiment of the present invention shown includes a power-off braking type electromagnetic brake brake 1, and a rectifier 2 for converting alternating current into direct current, and the output end of the rectifier 2 is connected to a power-off braking type electromagnetic holding brake The brake 1 is provided with a DC working voltage, and also includes an AC electromagnetic contactor 3 . The three-phase stator windings of the three-phase asynchronous motor have two lead wire ends for each phase winding. One end is called the head end and the other end is called the end end. It is stipulated that the head end of the first phase winding is represented by D1, and the end is represented by D4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com