Cutting method of long straight and narrow metal parts

A technology for metal parts and narrow strips is applied in the field of solving the blanking of long, straight and narrow strips of metal parts, which can solve the problems of difficult blanking of long, straight and narrow strips of metal parts, so as to solve the difficulty of blanking and improve blanking and size control. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but it should not be understood that the scope of the subject of the present invention is limited to the following examples. Without departing from the above-mentioned technical ideas of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the protection scope of the present invention.

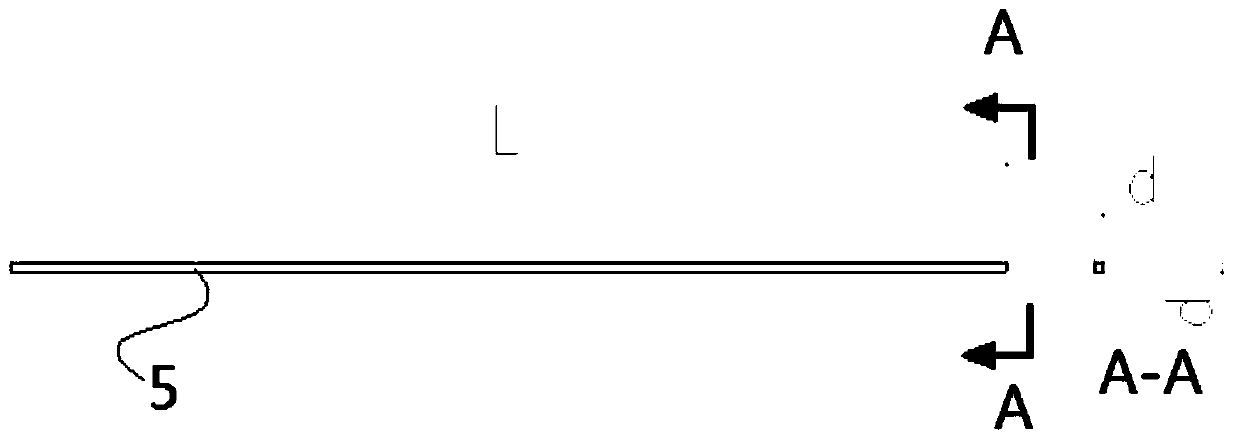

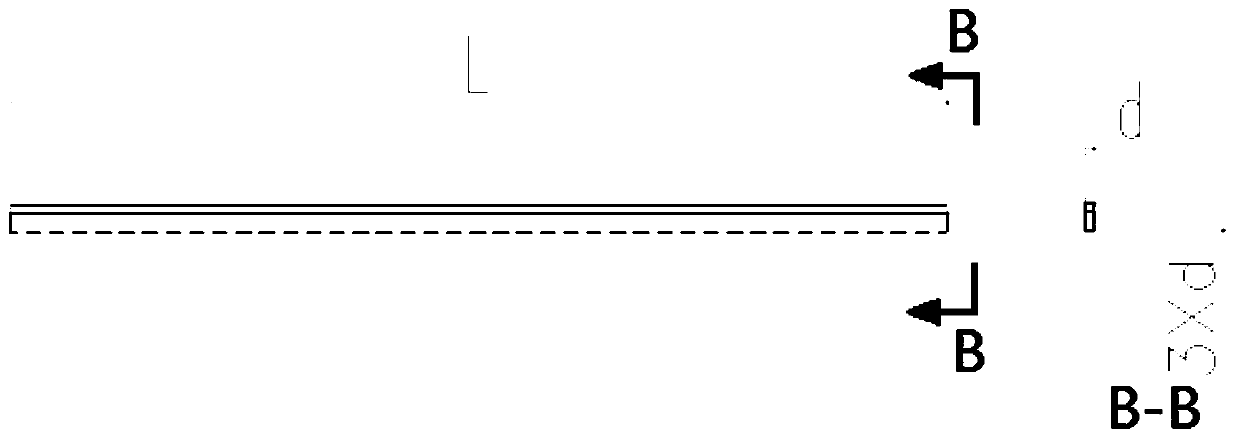

[0020] A blanking method for long straight and narrow metal parts is characterized in that: the length, width and height of the long straight and narrow metal parts are L, d and d respectively, and L is far greater than d.

[0021] When blanking

[0022] 1) Select a metal plate, cut out a part blank I1 whose length and width are L and d respectively, and the height is at least 3d.

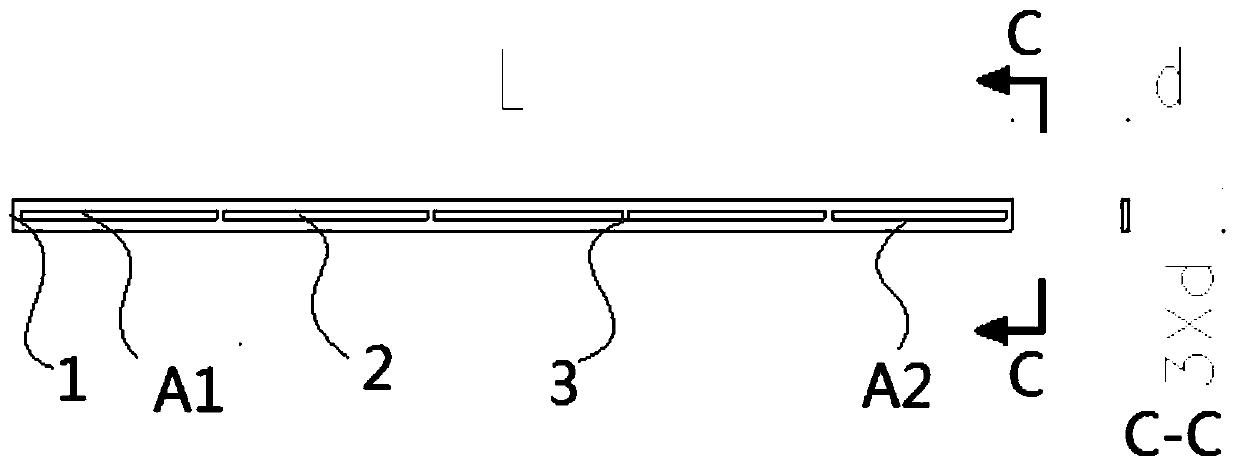

[0023] 2) such as image 3 As shown, several strip-shaped holes 2 are cut on the surface of the part blank I1 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com