Carton continuous conveying adjustment device for multiple length specifications

A technology of adjusting device and carton, applied in packaging and other directions, can solve the problems of affecting work efficiency, cumbersomeness, and high requirements for operators, and achieve the effects of reducing time and labor intensity, simplifying the adjustment process, and improving the adaptability range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solutions and beneficial effects of the present invention will be further described and illustrated below in conjunction with the above drawings.

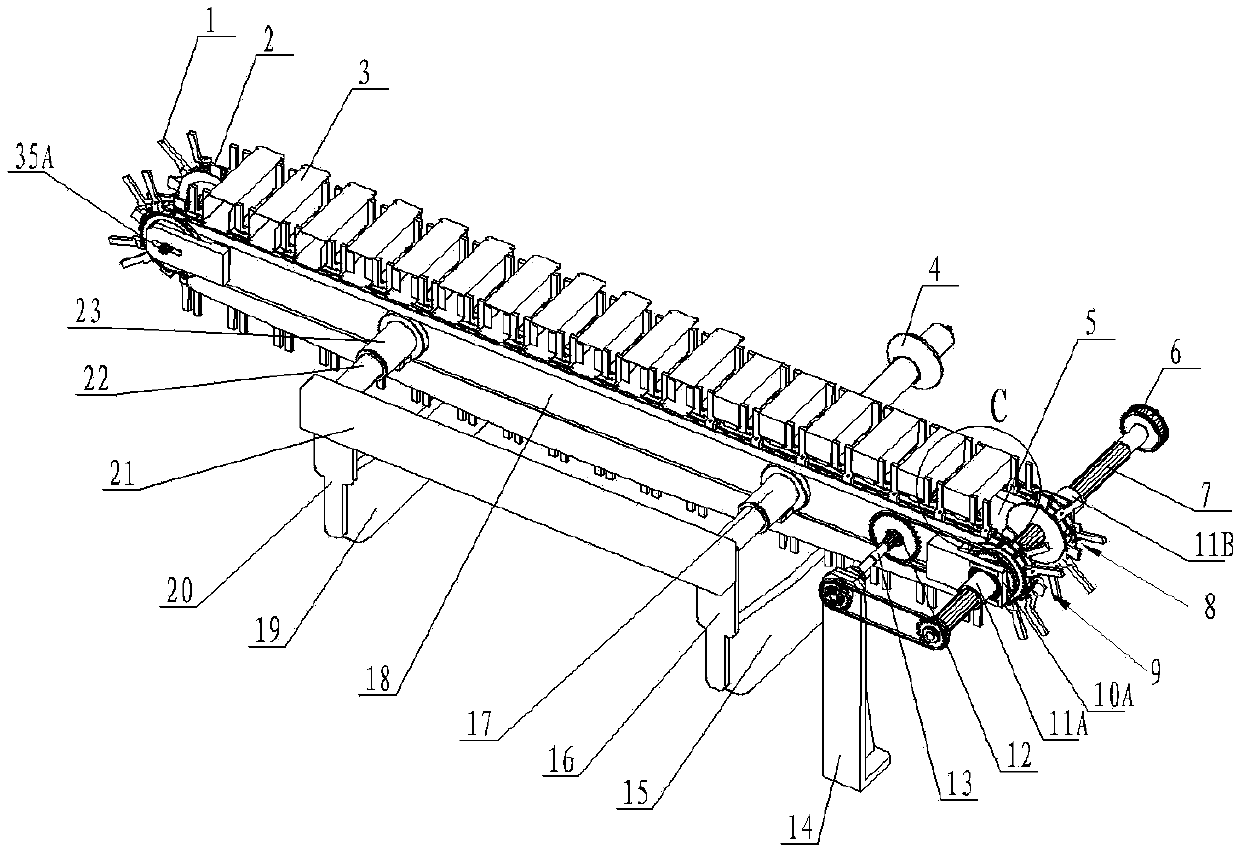

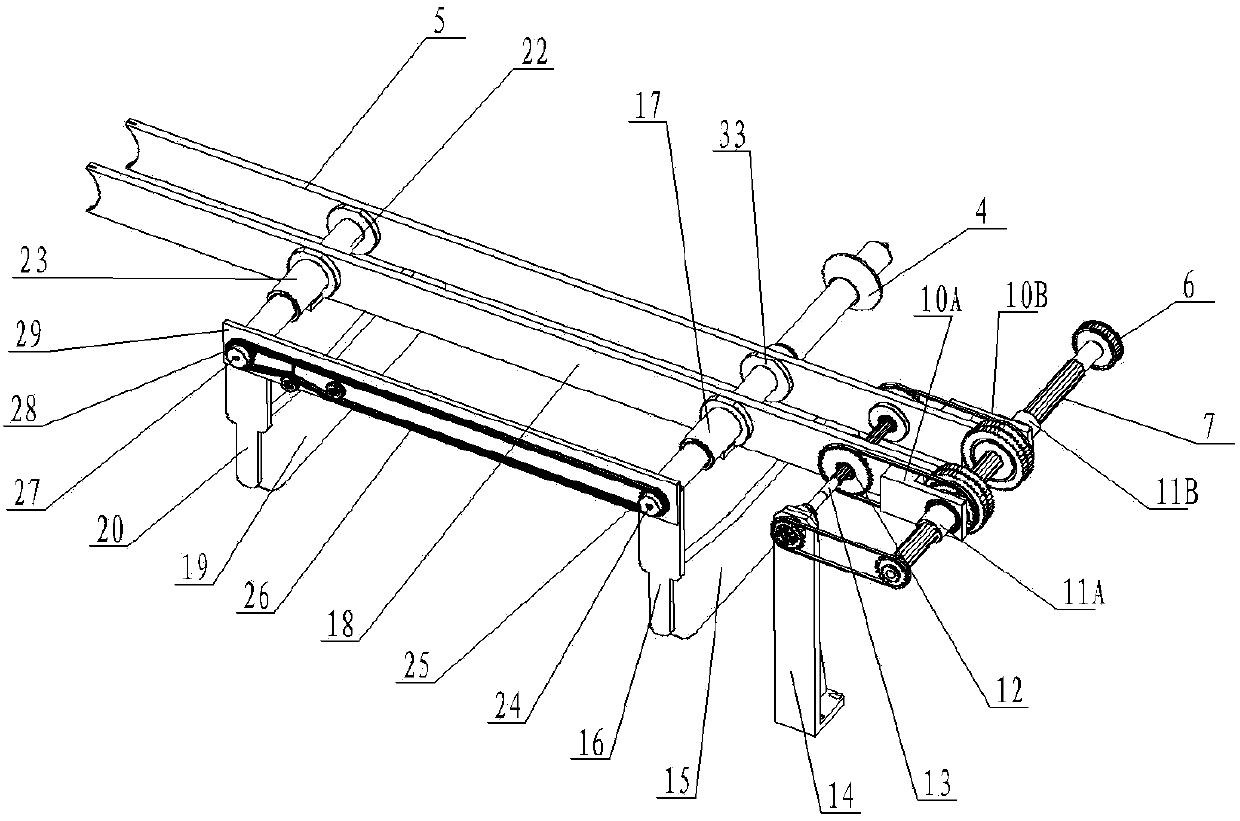

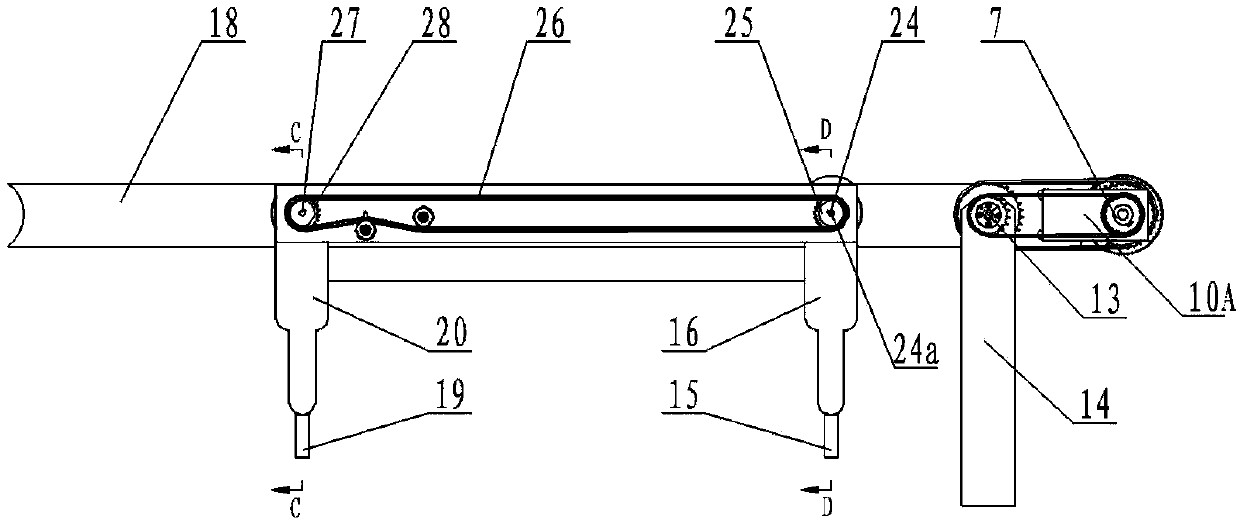

[0066] see figure 1 , 2 , refer to Figure 3-22 , the figure shows a carton continuous conveying adjustment device adapted to various length specifications related to the present invention, the key technical solution of which is:

[0067] The carton continuous conveying adjustment device adapting to various length specifications includes an inner conveying assembly 8 and an outer conveying assembly 9, and the inner conveying assembly 8 and the outer conveying assembly 9 are respectively fixed on the inner mounting plate 5 connected with the cartoning machine host and the outer On the mounting plate 18; the right end of the inner conveying assembly 8 and the outer conveying assembly 9 is provided with a shared spline main shaft 7; the spline main shaft 7 is driven by the drive wheel 6 and provides power for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com