Serration spindle driving system for electric saw

A technology of spindle drive and sawtooth, which is applied in the direction of metal sawing equipment, tool manufacturing of sawing machine devices, metal processing equipment, etc., can solve the problems of not meeting the precision requirements, not very high precision, and inconvenient, etc., to achieve protection in and out The effect of oil circuit, clear organization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

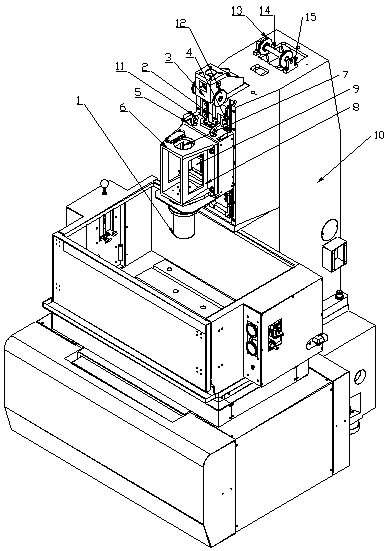

[0031] Such as figure 1 From the schematic diagram shown, it can be seen that the saw tooth for the electric saw of the present invention includes a main shaft, a driving slider, a driving guide rail, a proximity switch and a gantry frame.

[0032] Drive guide rail 4 has a pair, is symmetrically installed on the side wall of gantry 10, and the two ends of drive slide block 5 are respectively installed on two drive guide rails 4, and can be driven by drive unit and move up and down.

[0033] In the present invention, the driving device has two types of driving. The first driving device is a linear motor, which is installed on the gantry 10 and whose lower end is connected with the driving slider 5 .

[0034] The second kind of driving device is a driving screw 2, the upper end of the driving screw 2 is connected with the driving motor, and can be driven by the driving motor to rotate, the driving motor is installed on the upper end of the gantry 10 through the mounting base 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com