Grinding mechanism of abrasive belt grinder

A belt grinder and grinding technology, which is applied in the direction of belt grinder, grinding machine, grinding/polishing equipment, etc., can solve the problems of poor grinding effect, short service life, fixed, etc., and achieve the goal of processing Good effect, prolong service life, uniform grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

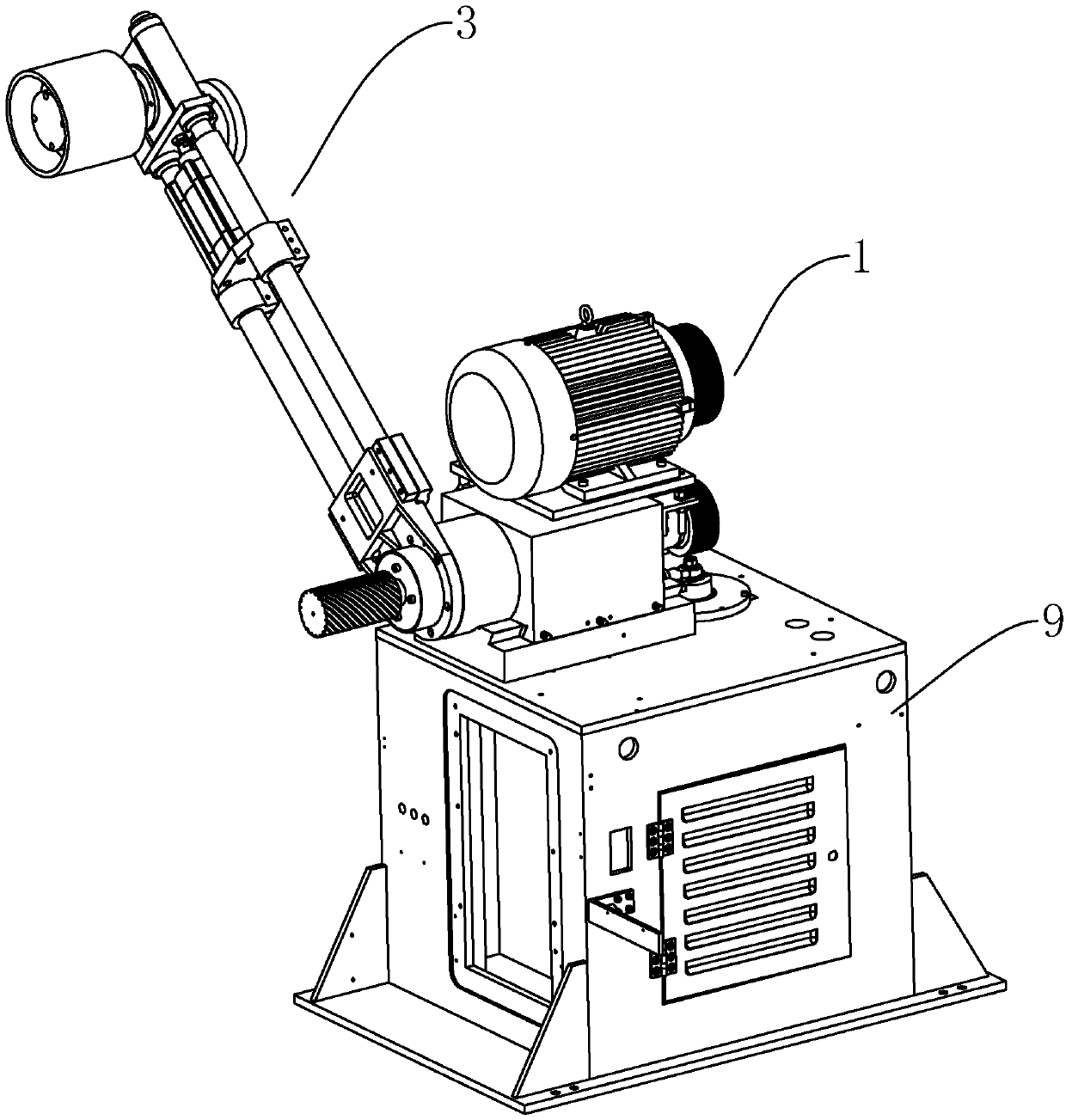

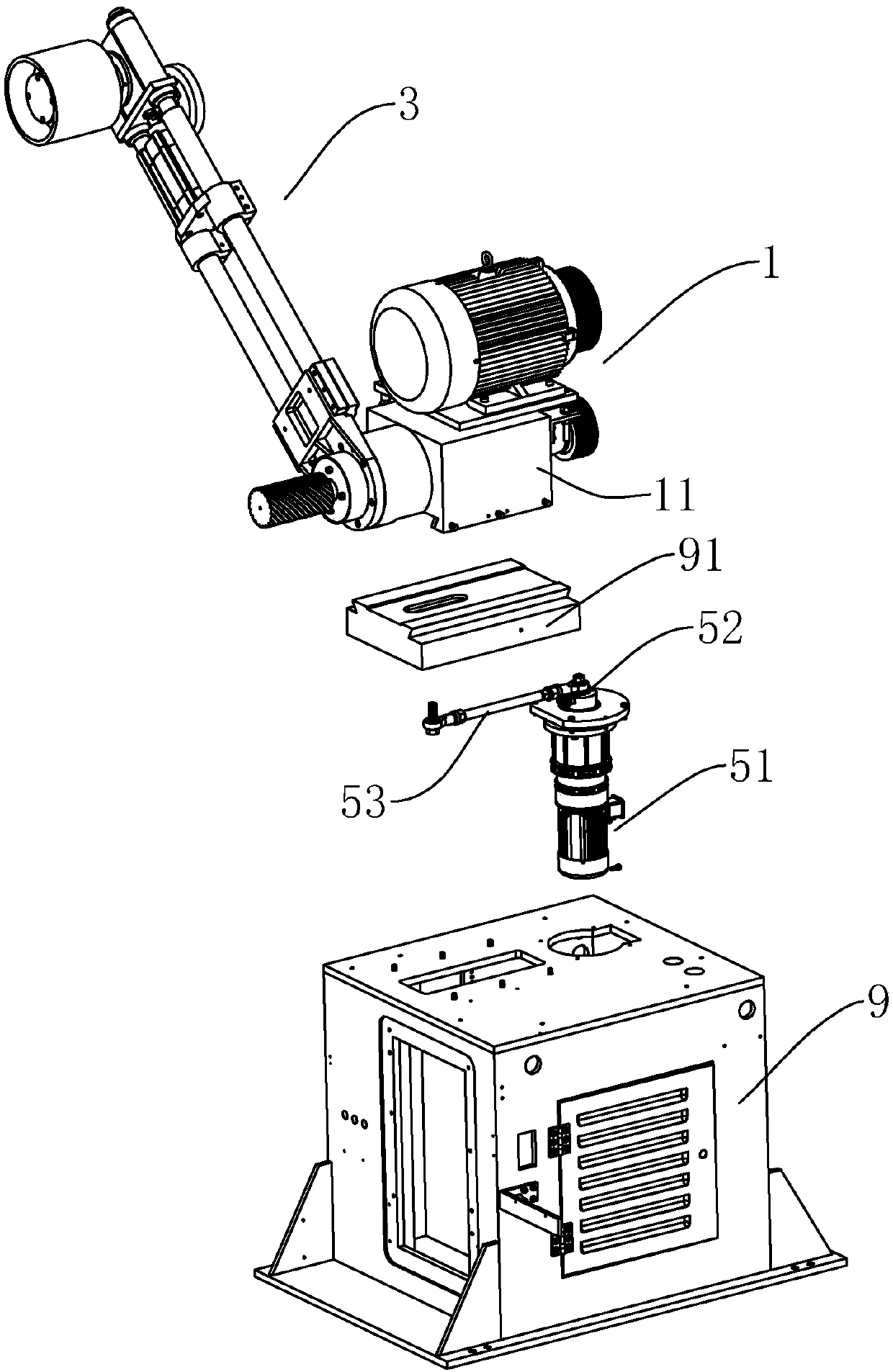

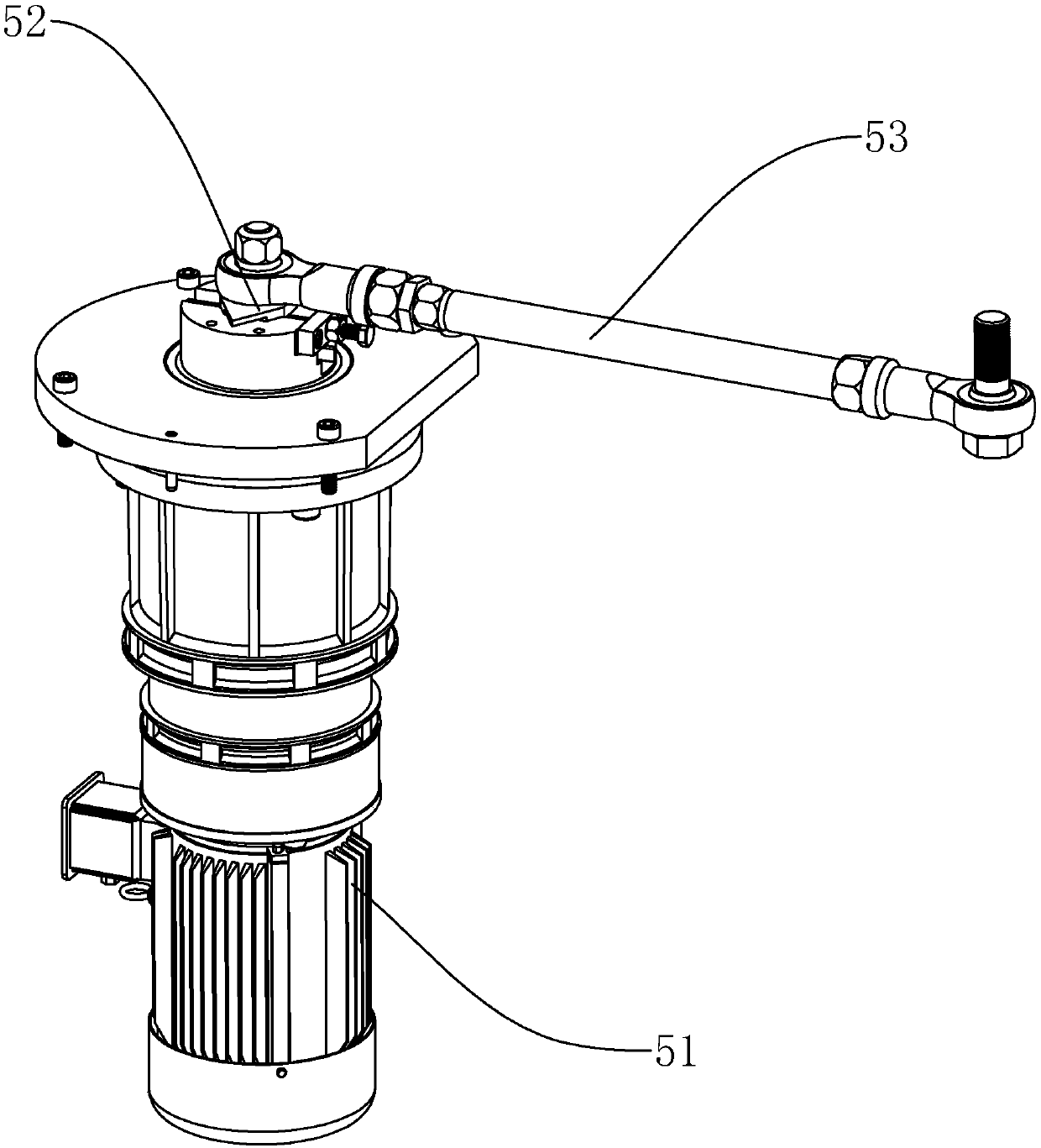

[0018] refer to Figure 1 to Figure 4 , Figure 1 to Figure 4 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, the grinding mechanism of the abrasive belt grinder includes a frame 9, a spindle mechanism 1 arranged on the frame 9, and an abrasive belt assembly 3 arranged on the spindle mechanism The main shaft mechanism 1 is slidingly arranged on the frame 9, and the frame 9 is equipped with a reciprocating drive mechanism capable of driving the main shaft mechanism 1 to reciprocate in the axial direction. When working, the abrasive belt assembly can be rotated for grinding , It can also move axially, so that the grinding is more uniform, the processing effect is good, and the wear position of the abrasive belt is dispersed, prolonging the service life of the abrasive belt.

[0019] Preferably, in this embodiment, the reciprocating drive mechanism is a slider crank structure, of course, in the specific implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com