An improved structure for preventing the entry of foreign objects between the inner and outer walls of the train

A technology for preventing foreign objects and walls, applied in railway car body, railway car body components, climate sustainability and other directions, can solve the problems of non-uniform size, inappropriate thickness of skids, hidden dangers, etc., to avoid fire hazards, Easy clean up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

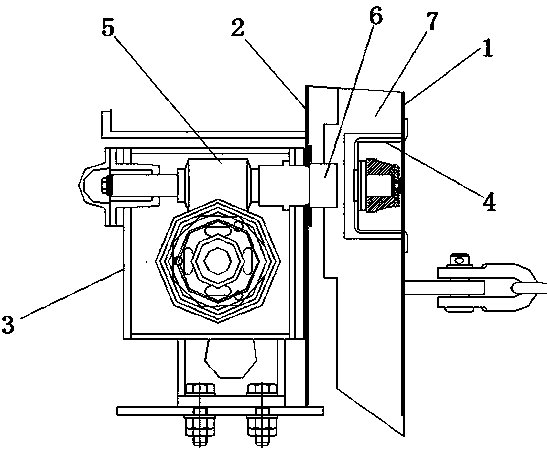

Image

Examples

Embodiment Construction

[0014] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] The invention relates to the field of railway vehicle brake system design, in particular to an improved structure suitable for preventing foreign matter from entering the connection between a railway vehicle hand brake device and an inner end wall, which can effectively prevent fire sources such as cigarette butts or other flammable substances from passing through the hand The central hole of the brake cover enters between the inner and outer end wall panels to cause accidents, and the operation safety of railway vehicles is very important, especially the fire protection requirements of vehicles. In order to meet the requirements, the invention is mainly aimed at the hand brake protective cover and the hand brake. The wood connection between the chassis bodies is not easy to fill the gap between the inner and outer end walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com