High-altitude balloon tearing system and high-altitude balloon tearing method of high-altitude balloon tearing system

A high-altitude balloon and tearing rope technology is applied in the field of adjacent space to achieve the effects of large load capacity, simple structure, and improved system safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

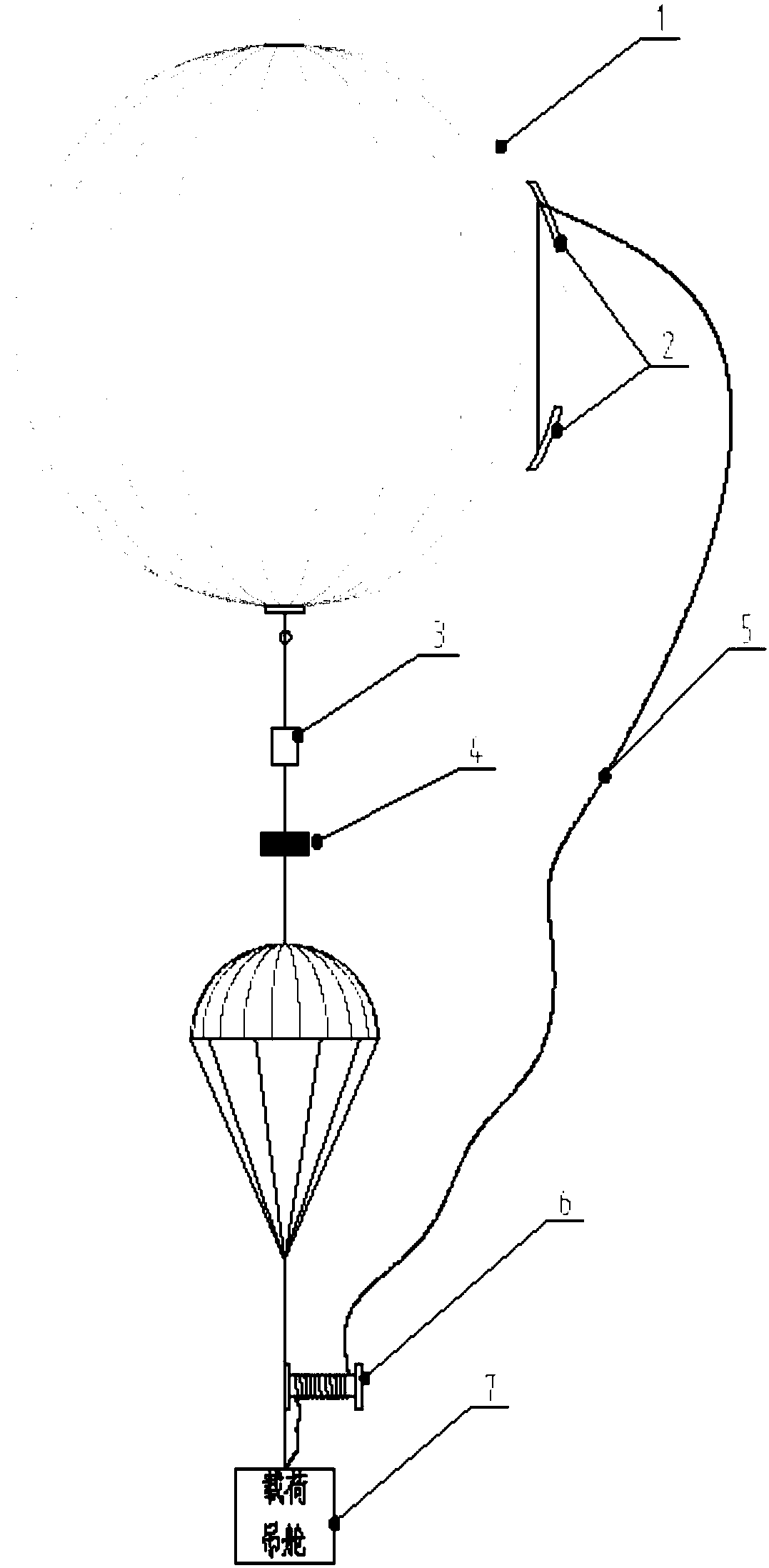

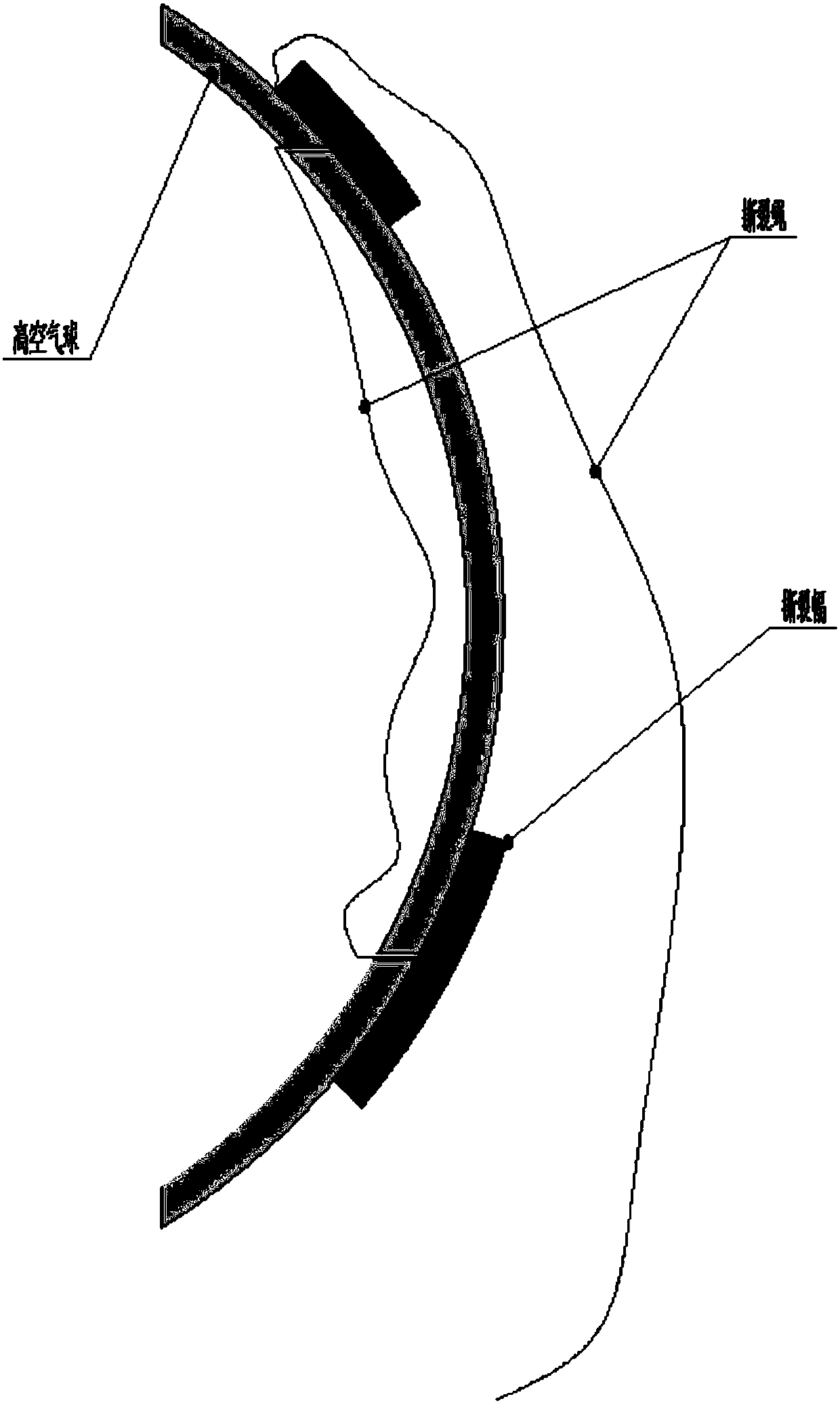

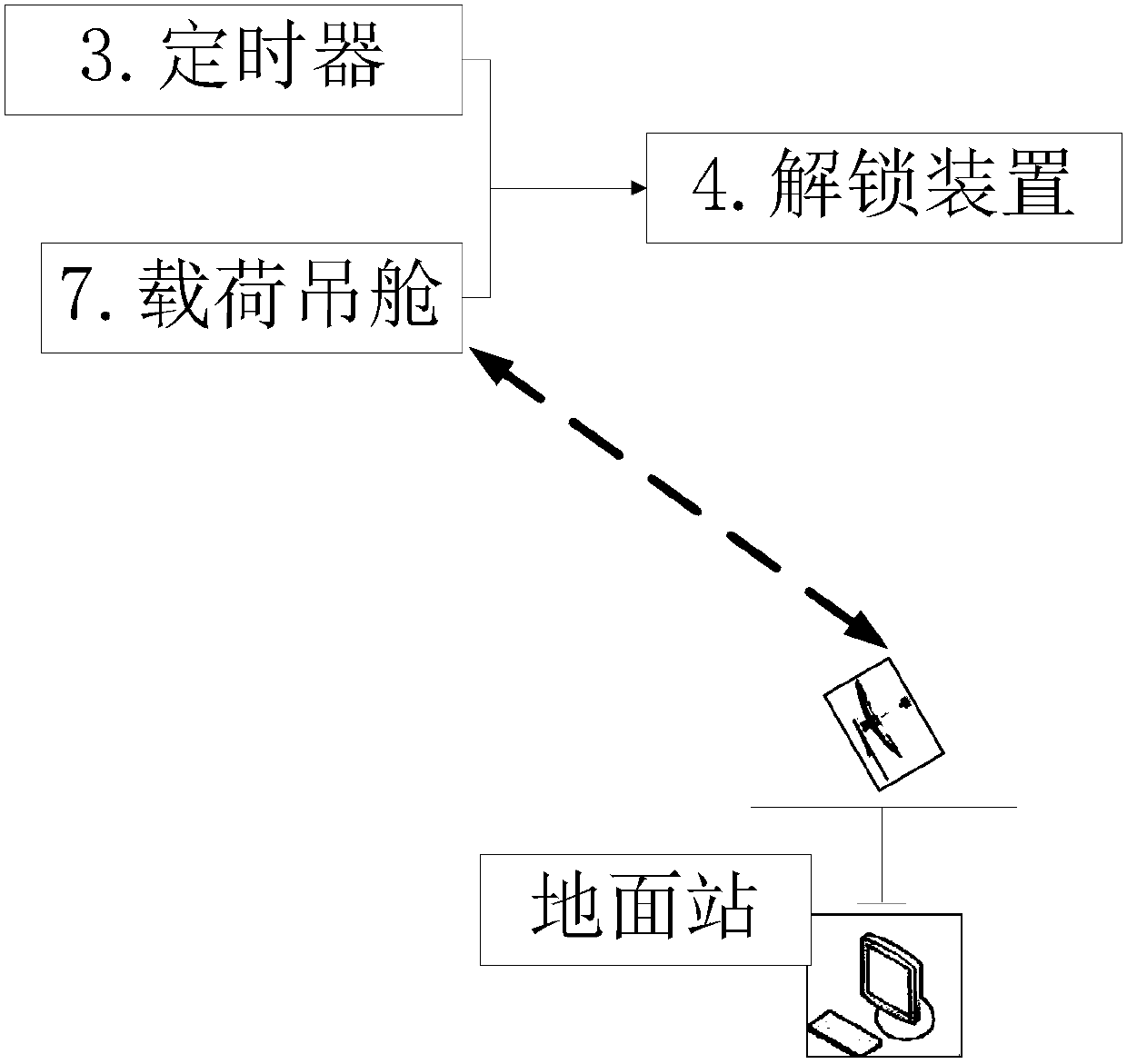

[0041] A high-altitude balloon fixed-height tearing system, which includes a high-altitude balloon body 1, a small hole 8, a tearing width 2, a tearing rope 5, a main load-bearing rope 9, a load pod 7, an unlocking device 4, and a rope winder 6 , timer 3, ground station, height sensor and satellite signal module;

[0042] The small hole 1 is arranged on the surface of the high-altitude balloon body 1 for pre-embedding the tear rope 5; the tear web 2 is a sheet of material attached to the small hole 8 on the outer surface of the high-altitude balloon body 1. Adhesive bonding or thermocompression bonding is applied to the position of the small hole on the surface of the high-altitude balloon body 1 for fixing the tearing rope 5 and sealing the small hole 8; one end of the tearing rope 5 passes through a small hole into the high-altitude The balloon body 1 is fixed in the small hole or at the junction of the tear web and the high-altitude balloon body 1; the other end passes thro...

Embodiment 2

[0052] A high-altitude balloon fixed height tearing method, it utilizes the high-altitude balloon fixed height tearing system of embodiment 1, comprises the following steps:

[0053] S1. Connect and fix the various parts of the system, wrap the excess tearing rope 5 on the rope winder 6, so that the length of the free part is greater than the length of the main load-bearing rope 9, so as to avoid the tearing rope 5 being damaged during the ascent of the system. force to destroy high-altitude balloons;

[0054] S2. Use the inflated high-altitude balloon body 1 to carry the load pod 7 to a predetermined height to perform a predetermined task;

[0055] S3. After the task is completed, the unlocking device 4 is triggered to separate the load pod 7 from the high-altitude balloon body 1 by triggering the timer 3 and / or issuing an unlocking command at a specified height by the ground station; when the timer 3 and the ground station issue an unlocking at the same time command, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com