Jeans whisker polishing device

A technology of cat whiskers and denim, applied in the field of garment processing, can solve the problems of low efficiency, energy consumption, and inability to guarantee the same effect of cat whiskers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

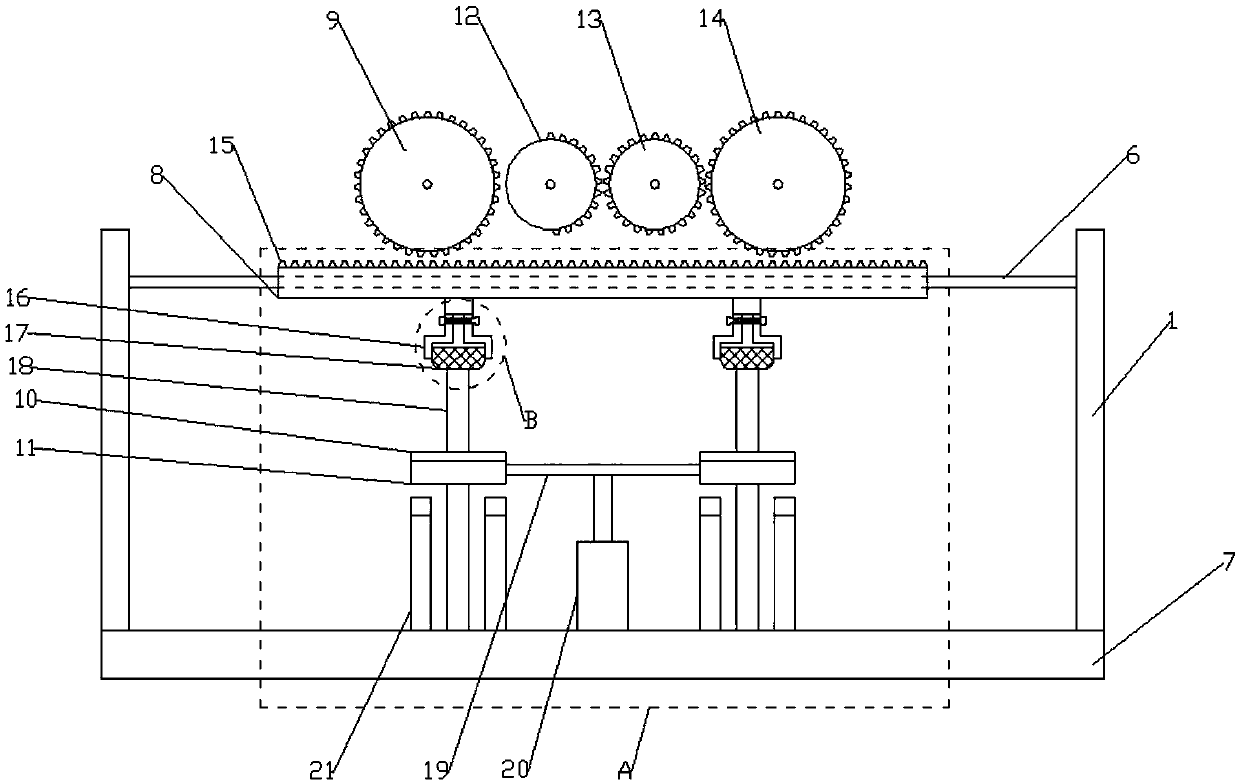

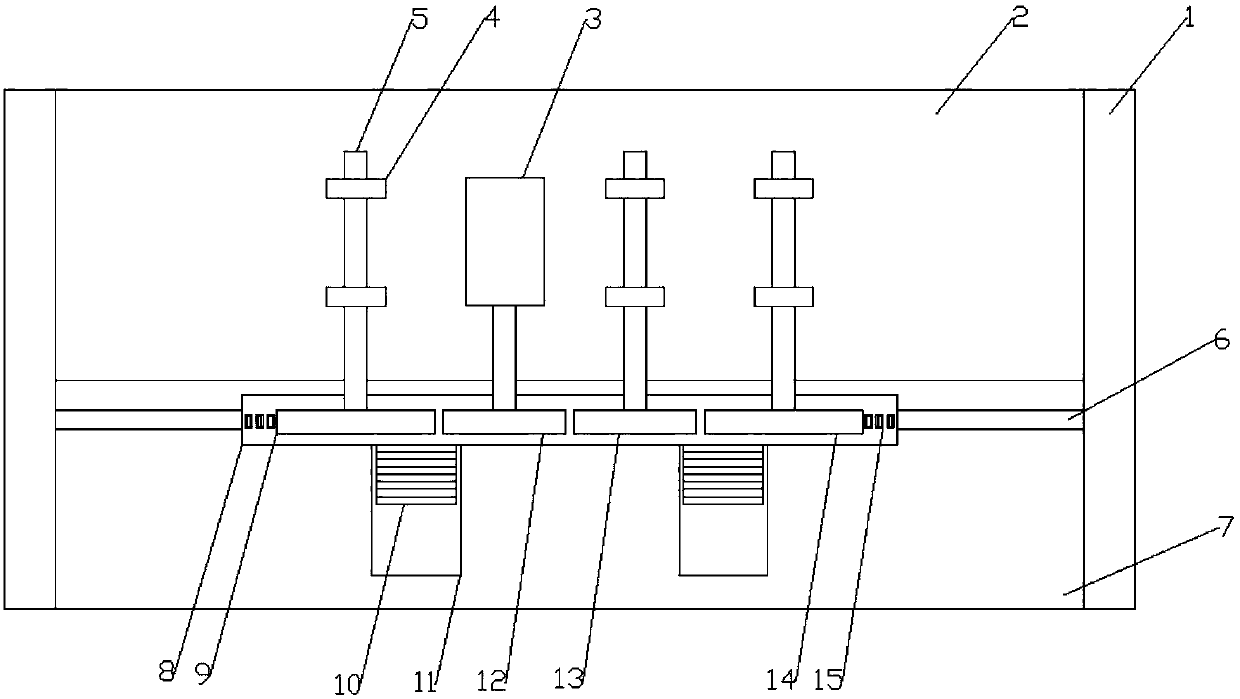

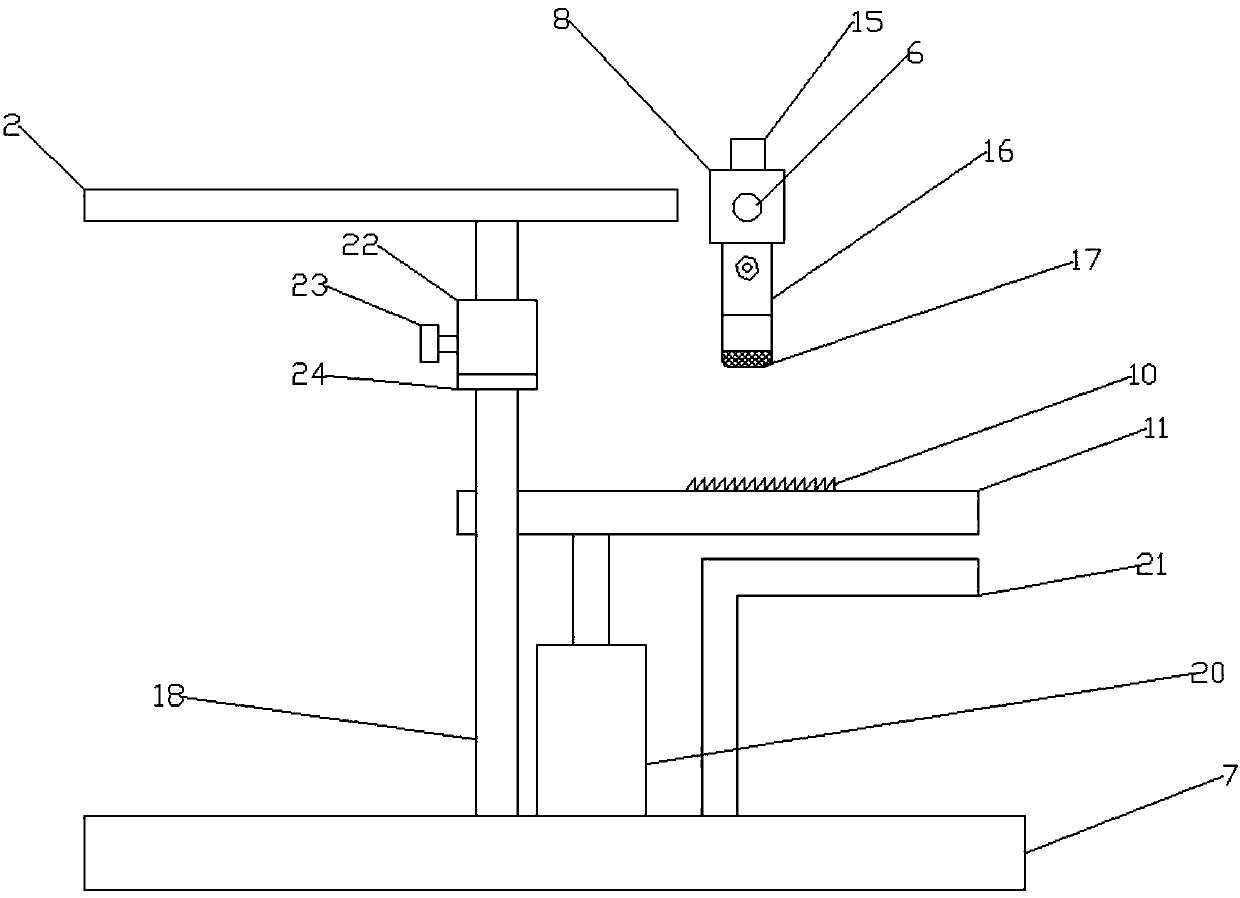

[0018] Figure 1-5 Show the specific embodiment of the present invention: a kind of polishing device of cowboy cat whisker, comprise base 7, be provided with linear drive device 20, two guide rods 18 and four L frames 21 on described base 7, described linear drive device 20 upper end is provided with connecting rod 19, and the two ends of described connecting rod 19 are provided with formwork seat 11, and described formwork seat 11 is provided with cat whisker fold 10, and described formwork seat 11 is slidably connected with guide bar 18, and described guide The rod 18 is provided with a limit sleeve 22, the limit sleeve 22 is provided with a fixing bolt 23, the two ends of the base 7 are provided with a side plate 1, and the upper end of the side plate 1 is provided with a slide bar 6 and a support plate 2, The support plate 2 is provided with a motor 3 and six support frames 4, and each of the two support frames 4 is provided with a rotating shaft 5, and the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com