Experimental process and equipment of repeated perforation of same hole

A process and experimental technology, applied in the fields of fluid production, measurement, wellbore/well components, etc., can solve the problems of inability to realize, inability to perform repeated perforation experiments in the same hole, and inability to perform repeated perforation experiments in the same hole, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

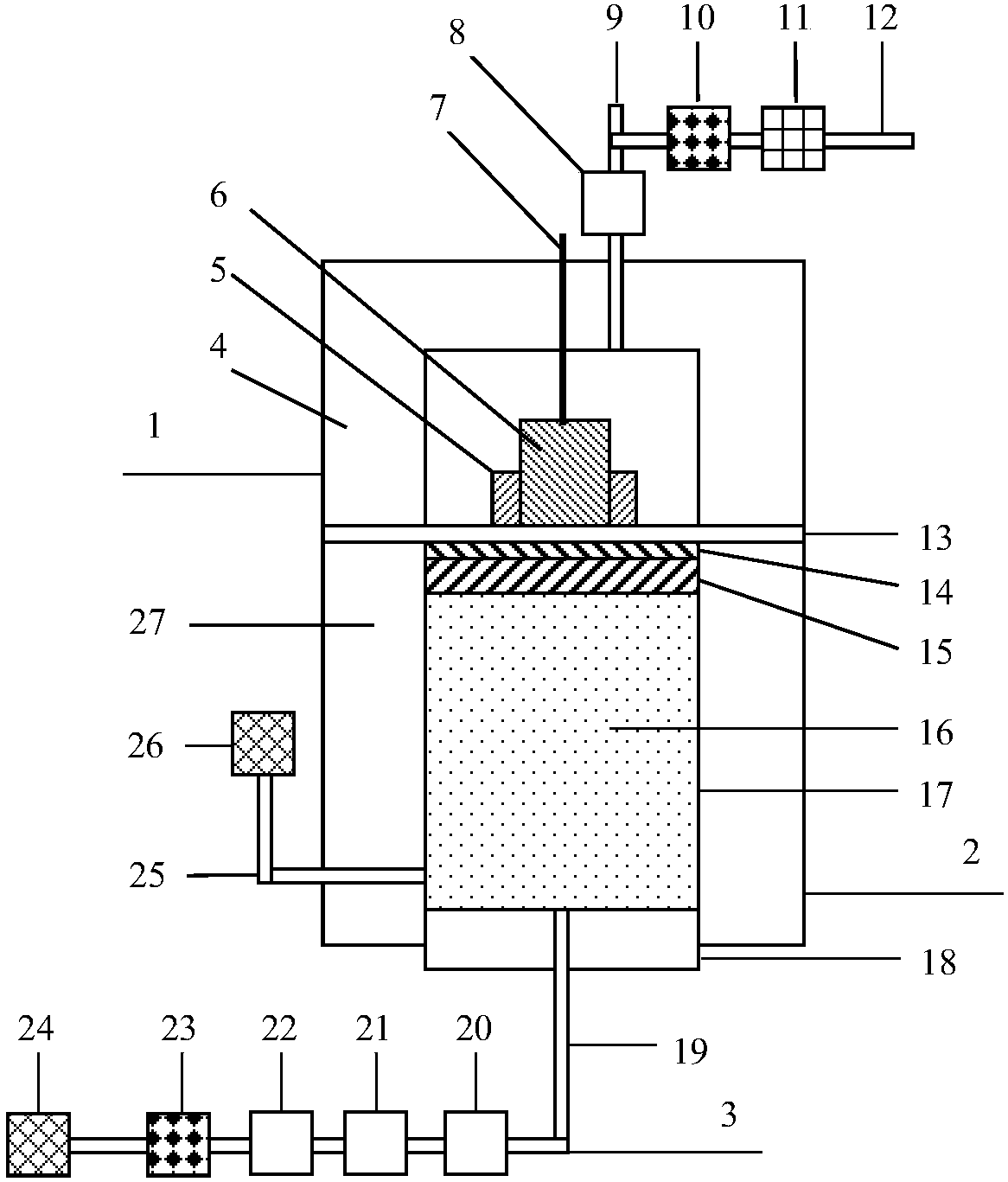

[0017] The specific embodiment: the present invention will be described in further detail below in conjunction with the accompanying drawings. The present invention is realized through the following technical solutions: the same hole repeated perforation experiment process and device, and this process is realized through the following devices: it is simulated by well pressure And perforation system 1, confining pressure simulation system 2, pore pressure simulation system 3;

[0018] The well pressure simulation and perforation system 1 consists of a well pressure simulator 4, a locator 5, a concentrated energy perforator 6, a detonation line 7, a well pressure measurement device 8, a well pressure pressurization tube 9, a well pressure accumulator 10, The overflow controller 11 and the return pipeline 12 are composed; the positioner 5 is screwed on the connection end surface 13, the energy-concentrating perforator 6 is placed in the positioner 5, and the detonating line 7 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com