Shock-proof shock absorber based on spiral sheet

A technology of helical blade and shock absorber, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve problems such as increasing the complexity of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

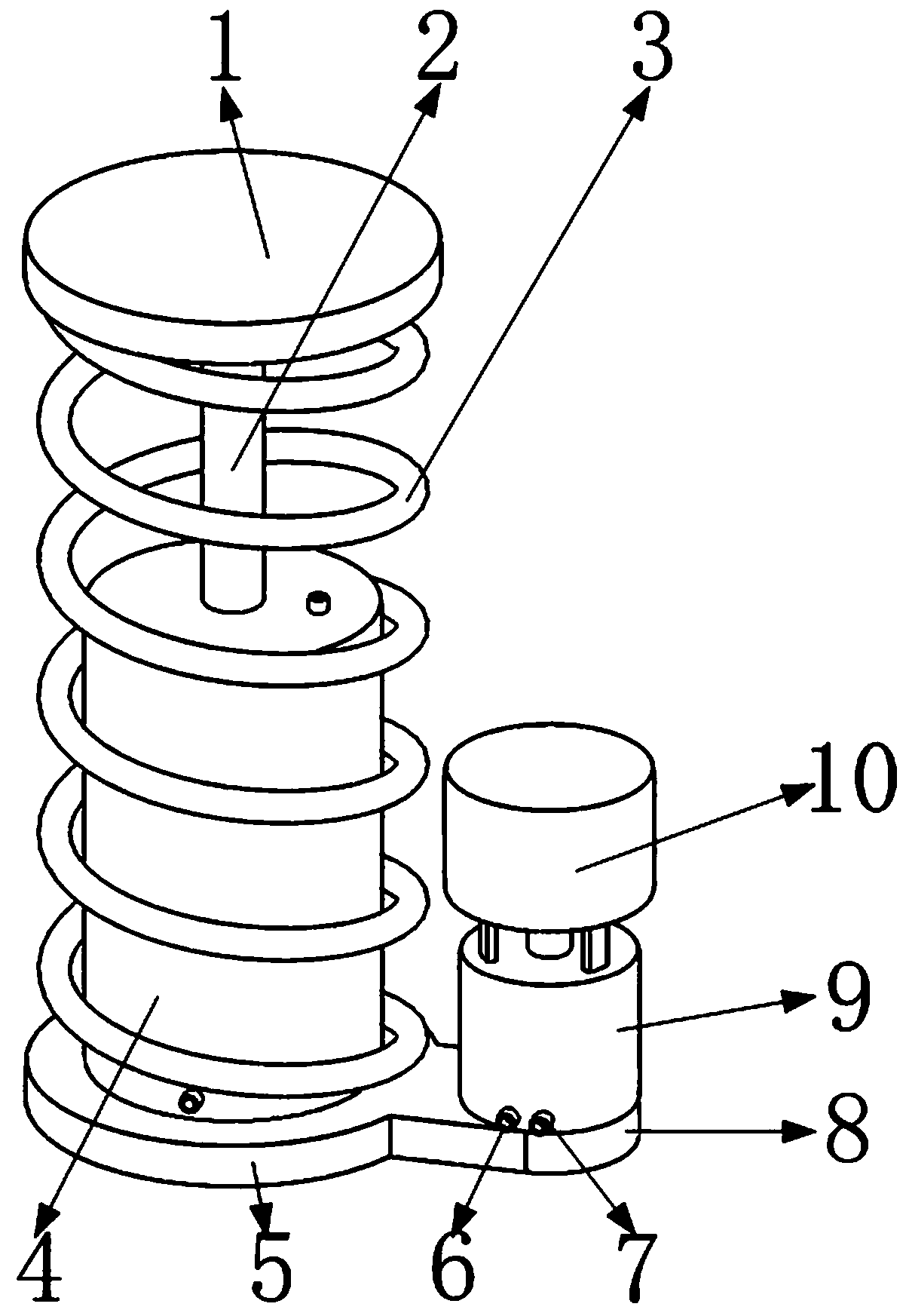

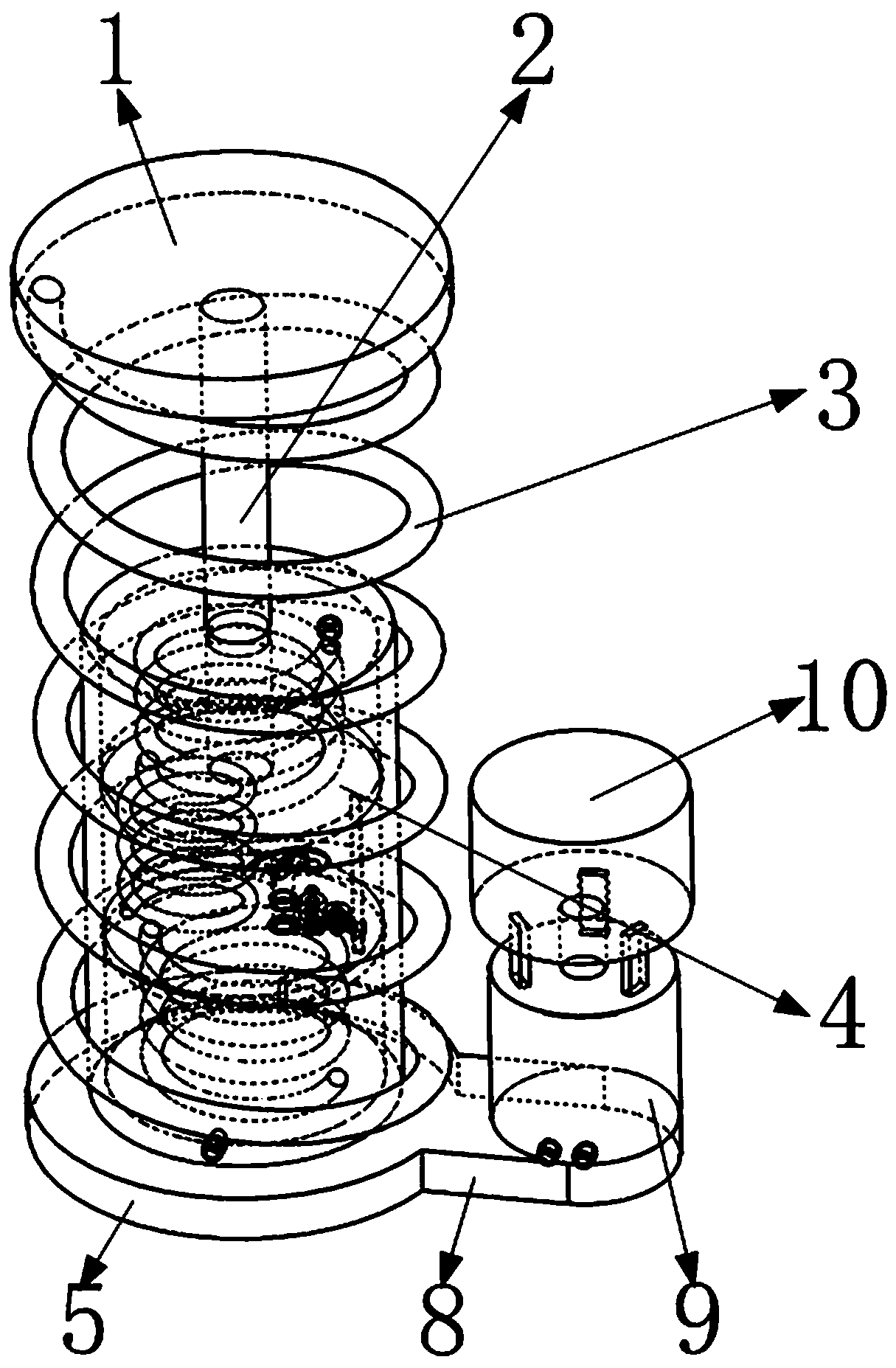

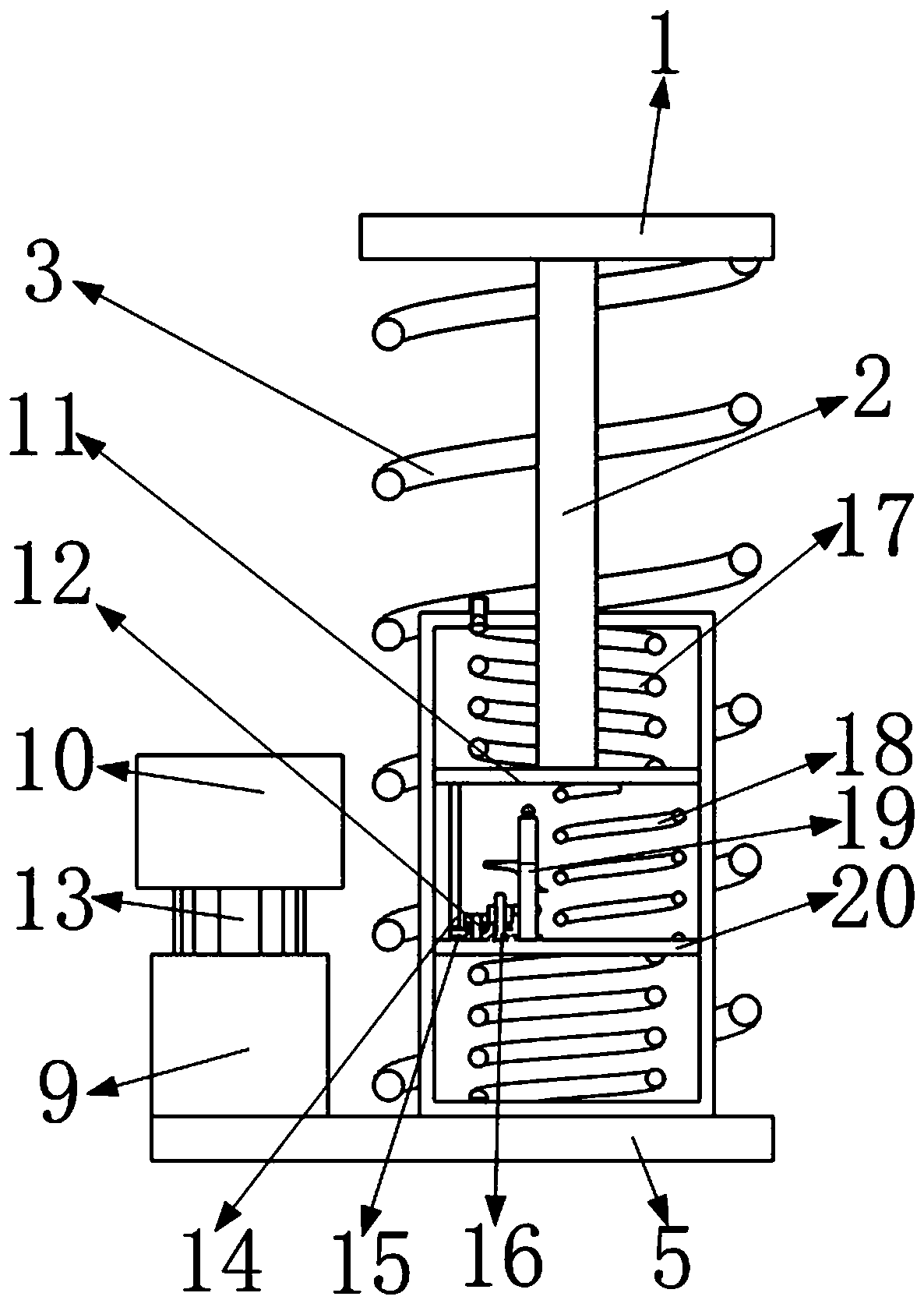

[0053] Specific embodiments: when people use the damping mechanism designed by the present invention; when the upper support plate 1 is hit; the upper support plate 1 will be compressed and move downward; the upper support plate 1 will compress the shock absorbing spring when it moves downward 3. The damping spring 3 has the effect of shock absorption; at the same time, the downward movement of the lower support plate 5 will drive the push rod 2 to move downward; the downward movement of the push rod 2 will drive the upper piston plate 11 to move downward; the upper piston plate will move downward. 11 moves downward and will stretch the compression spring 17; while the upper piston plate 11 moves downward and will drive the lower piston plate 20 to move downward through the buffer spring 18; The high-pressure helium between the piston shells will flow into the air motor 9 through the piston outlet pipe 34 and the motor air inlet 6; the gas flowing into the air motor 9 will make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com