Connector adopted by vertical elbow bus duct and processing technology thereof

A technology of busway and connectors, which is applied in the direction of fully enclosed busbar devices, etc., can solve the problems of heat generation, economic loss, and detection difficulties in the welding parts of busway, and achieve the prevention of insufficient pressure resistance, excellent corrosion resistance, and improved connectors. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

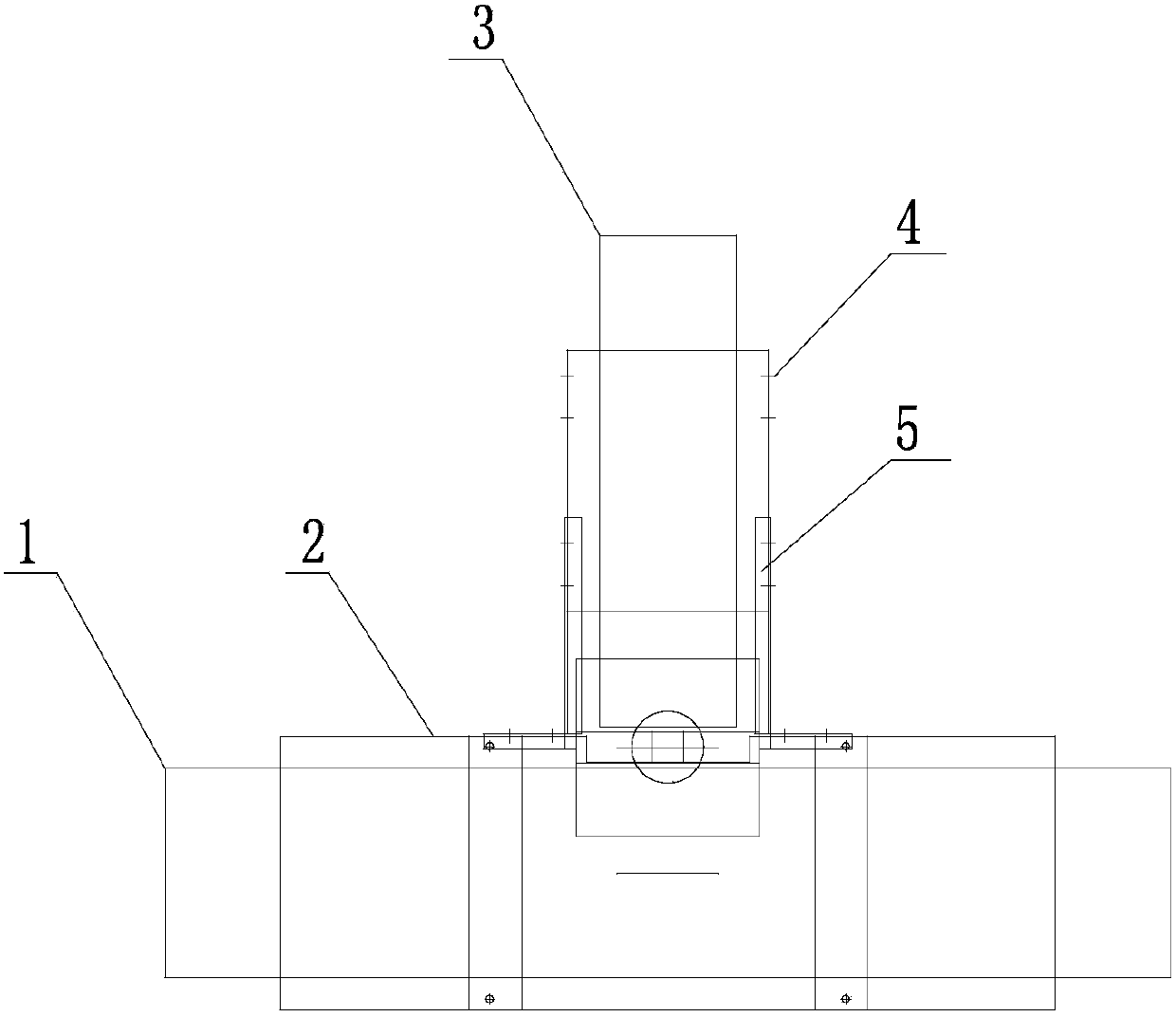

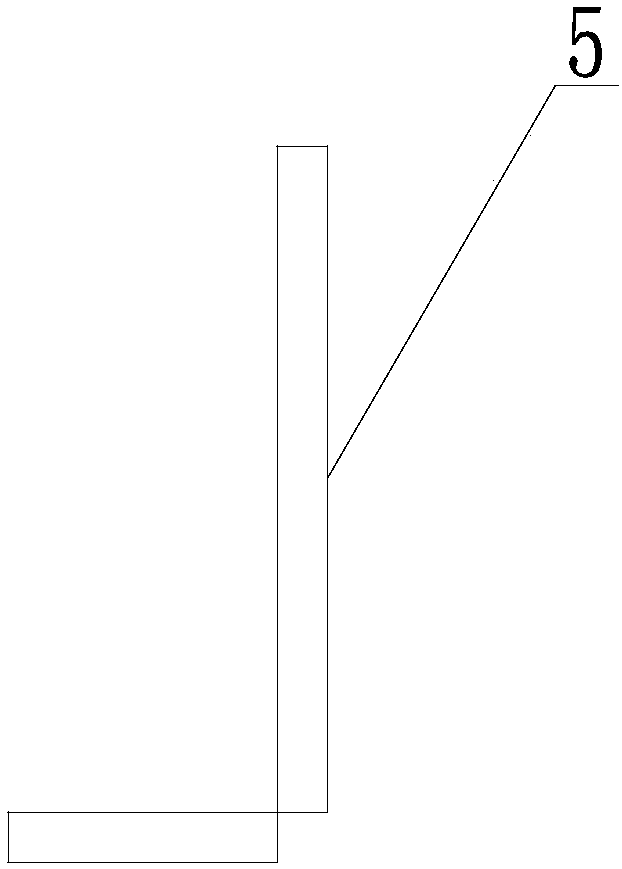

[0027] The vertical elbow bus duct of this embodiment adopts a connector, such as figure 1 and 2 As shown, it includes a horizontal conductor 1, a vertical conductor 3, a horizontal casing 2, a vertical casing 4 and an L-shaped connecting plate 5, the horizontal conductor 1 and the vertical conductor 3 are fixed by bolts, and the horizontal casing 2 and the vertical casing 4 are set Outside the horizontal conductor 1 and the vertical conductor 3 , the horizontal casing 2 and the vertical casing 3 are fixedly connected by an L-shaped connecting plate 5 . The diameter of the transverse conductor is 100mm. The diameter of the vertical conductor is 130mm.

[0028] The processing technology of the vertical elbow busway of the present invention using a connector comprises the following steps:

[0029] (1) Make horizontal shell, vertical shell and L-shaped connecting plate, as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com