Conical plug pin and plug bush for socket and plug

A technology of tapered sleeves and sockets, applied in the direction of contact parts, etc., can solve the problems of loose contact between pins and sockets, easy to heat and burn, small effective contact area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

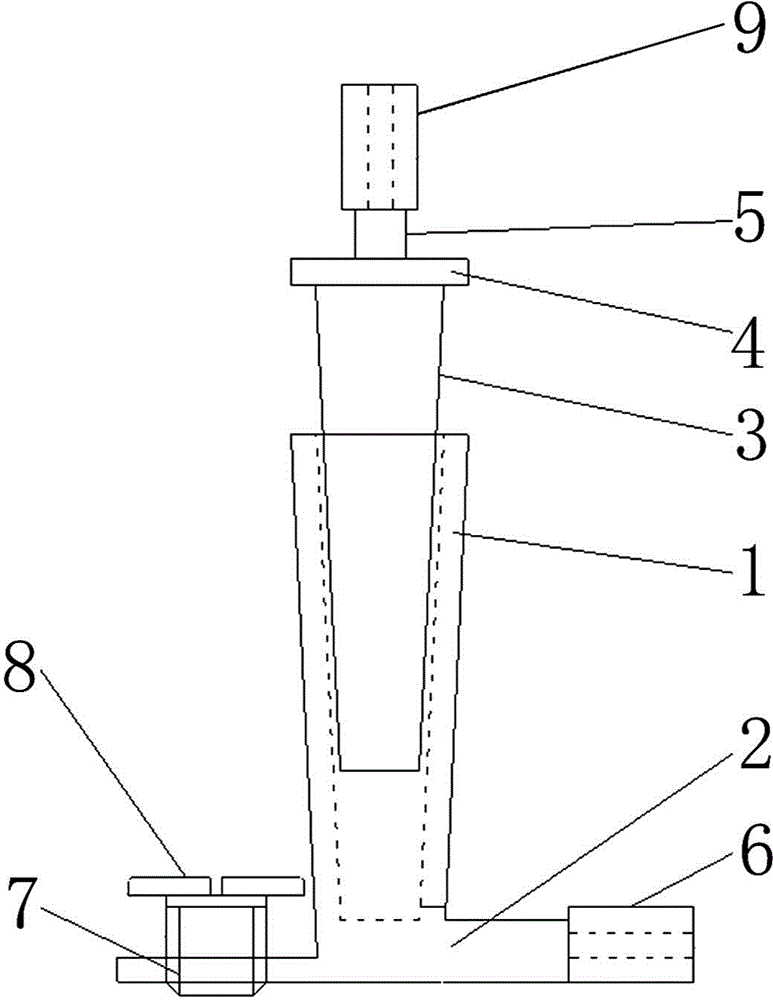

[0009] A kind of tapered pin and socket for socket and plug, including a socket part and a pin part; the socket part includes a tapered sleeve 1, a disk-shaped connecting plate 2; the pin part includes a tapered pin head 3, Disk-shaped positioning platform 4, cylindrical connector 5; wherein, the thin end of tapered sleeve 1 is closed, and the thick end of tapered sleeve 1 is provided with opening; The thin end face of the shaped sleeve 1 is fixed as a whole; the thin end of the tapered pin head 3 is movably inserted into the inner cavity of the tapered sleeve 1; The end faces are fixed as a whole; the lower end face of the cylindrical connector 5 and the center of the upper table of the disc-shaped positioning table 4 are fixed as a whole.

[0010] During specific implementation, the socket part also includes a socket connection tube 6, a screw hole 7, and a screw 8; the plug part also includes a plug connection tube 9; The right side is fixed as a whole; the screw hole 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com