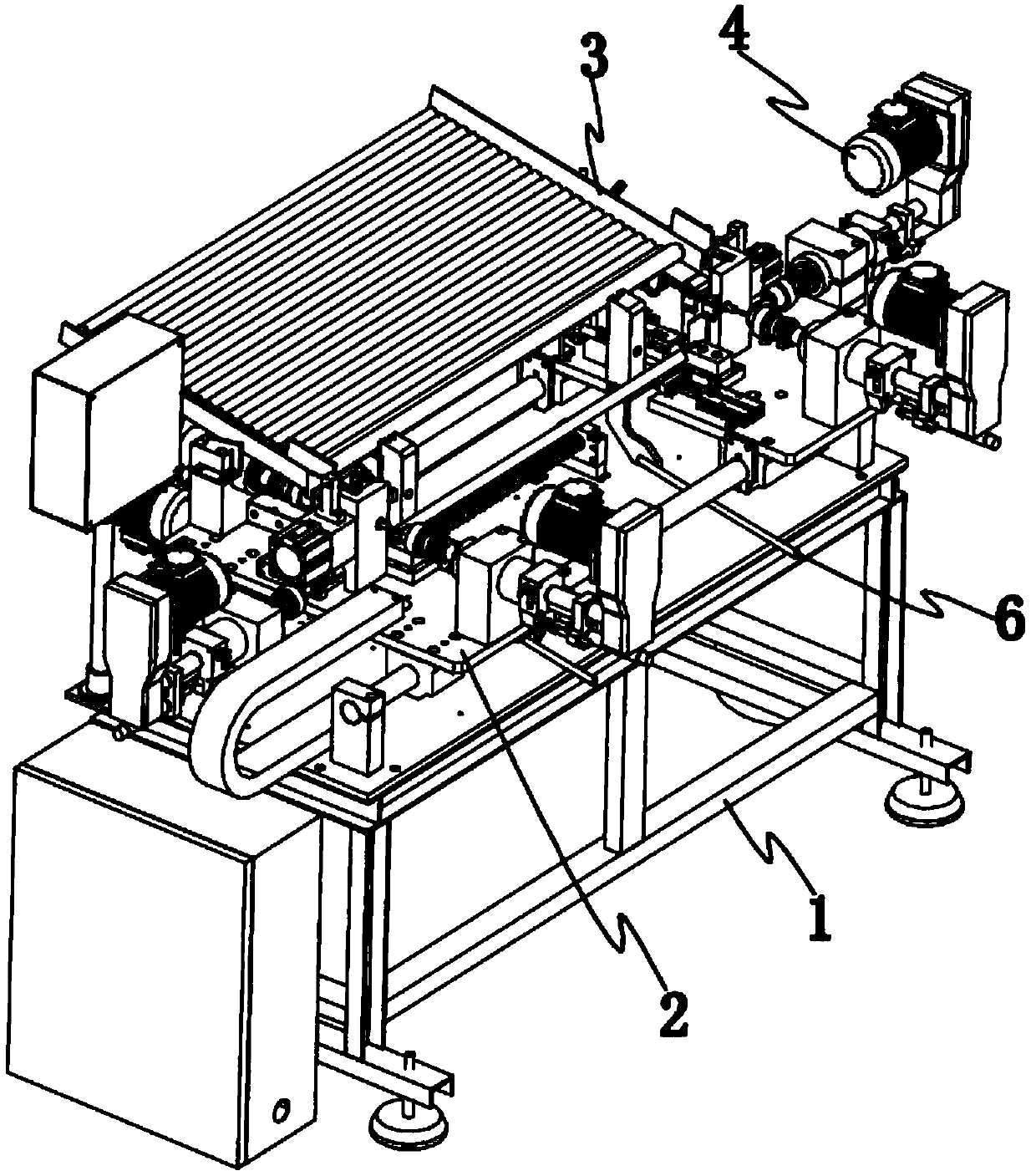

A drilling and chamfering device suitable for processing steel pipes of different sizes

A chamfering device and technology for steel pipes, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of increasing equipment and labor production costs, affecting the production efficiency of steel pipes, etc., to reduce equipment investment costs, facilitate adjustment and use, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

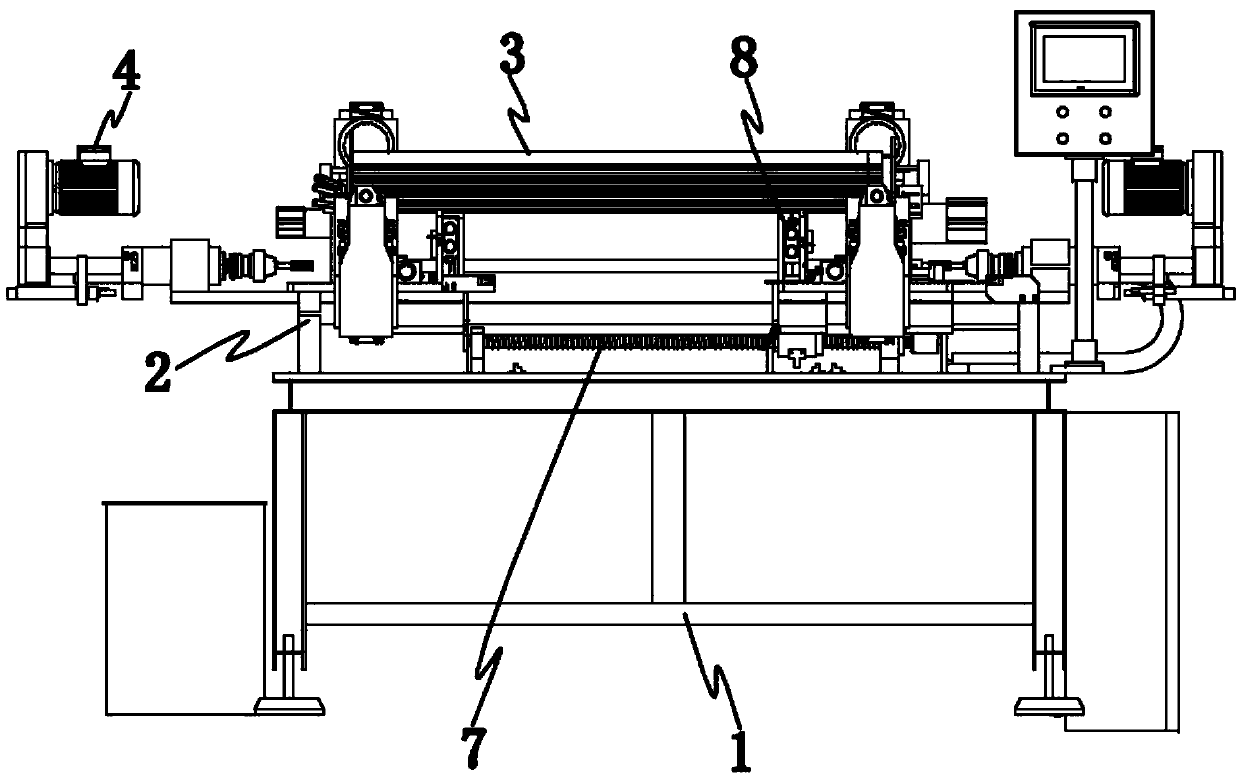

[0037] This device first puts steel pipes one by one from the high outer end of the steel pipe importing frame edge 302 of the steel pipe drilling clamping mechanism 3, and the steel pipe erected on the steel pipe importing frame edge 302 is under the action of gravity, along the steel pipe importing frame edge 302 Rolling down, finally blocked by the upper end limit of the steel pipe limit column 805 of the steel pipe jacking input mechanism 8, when the steel pipe is input and processed, the jacking cylinder 802 of the steel pipe jacking input mechanism 8 is started, and the piston of the jacking cylinder 802 The driving plate 803 on the rod drives the jacking block 807 to move upward along the clamping groove 806 of the steel pipe limiting column 805, so that the steel pipe is ejected from the steel pipe limiting column 805 side to the steel pipe importing frame edge 302, and rolled into the The drilling of the steel pipe drilling and clamping mechanism 3 fixes the notch at t...

Embodiment 2

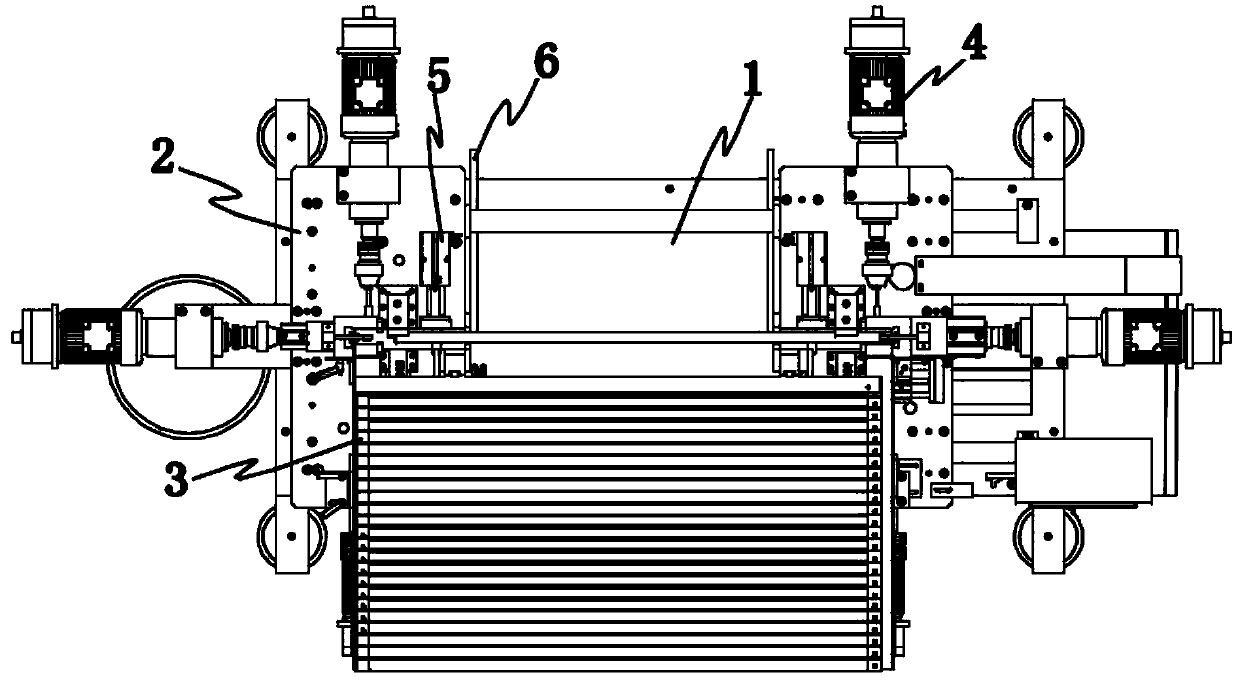

[0039] When the device drills the steel pipe, the steel pipe rolled into the upper notch of the drilling clamping groove block 301 of the steel pipe drilling clamping mechanism 3 is lifted by the adjustment block 304 on the side end groove of the drilling clamping groove block 301 , then start the drilling clamping drive cylinder 303, the drilling clamping drive cylinder 303 piston rod passes through the drilling clamping groove block 301 and connects with the two ends of the steel pipe, so as to realize the fixing of the steel pipe, then start the steel pipe drilling The processing tool driving mechanism 4 on the front and rear sides of the hole clamping mechanism 3, the driving motor 402 of the processing tool driving mechanism 4 drives the rotating drive shaft 403 to rotate through the belt transmission mechanism, and the rotating driving shaft 403 drives the processing tool 407 at the front end to rotate together. When the side pipe surface of the steel pipe is drilled, the...

Embodiment 3

[0041] The device firstly drills the steel pipe, and then chamfers the end of the pipe. After the steel pipe is drilled in the drilling clamping groove block 301 of the steel pipe drilling and clamping mechanism 3, the steel pipe clamps the groove The processing groove of the block 301 falls onto the slot 204 on the opposite end faces of the left workbench 203 and the right workbench 201, wherein the steel pipe is supported by the steel pipe of the steel pipe chamfering clamping mechanism 5 on the cylinder 504 piston rod The rod 505 lifts the steel pipe on the slot 204, and then starts the chamfering and clamping drive cylinder 501 of the steel pipe chamfering and clamping mechanism 5, clamps the steel pipe by the fixed clamp block 503 and the movable clamp block 502, and then starts the steel tube The processing tool driving mechanism 4 on the outer surface of the drilling clamping mechanism 3 performs chamfering processing on the two ends of the steel pipe. In situ, the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com