Guide driving external float clamping tool

A floating clamping and tooling technology, applied in the field of clamping tooling, can solve the problems of poor clamping effect, large assembly workload, complicated structure design, etc., and achieve the effect of good clamping effect, low manufacturing cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

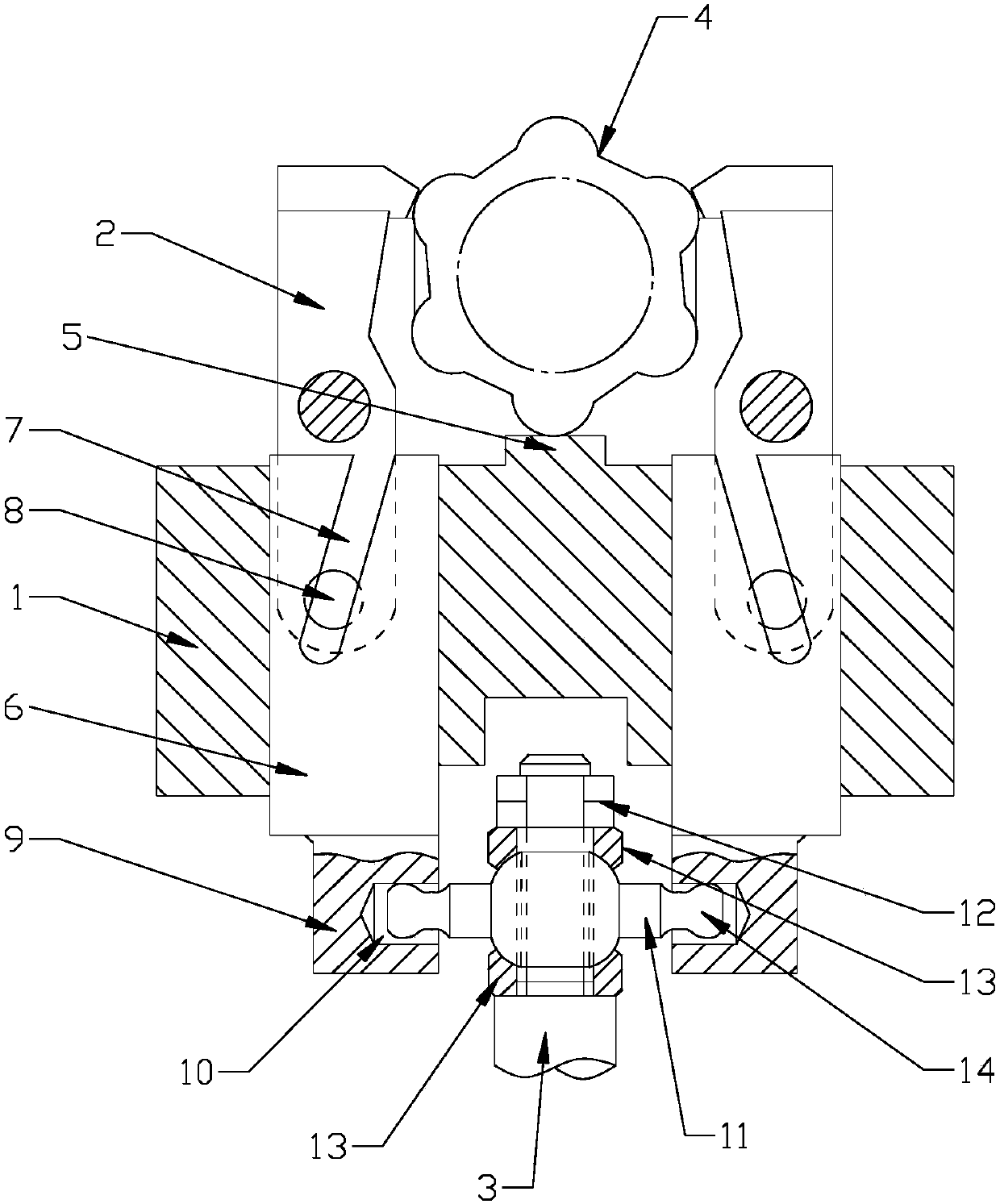

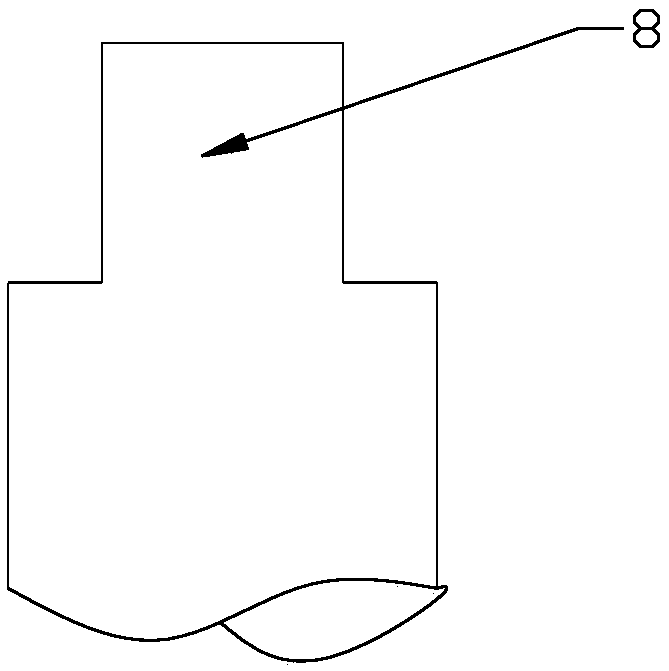

[0014] Such as figure 1 , figure 2 As shown, the present invention provides a guide-driven external floating clamping tool, including a base 1, jaws 2 and a drive rod 3, wherein, the base 1 is provided with a support table 5 for supporting the workpiece 4, and the base 1 Two guide blocks 6 are oppositely arranged, and the guide blocks 6 are axially slidably matched with the base 1. The upper parts of the guide blocks 6 are provided with guide grooves 7, and the guide grooves 7 are in the shape of "eight"; The holding surfaces are opposite and the middle part of the jaw 2 is hinged with the base 1. The top of the jaw 2 is provided with a chuck for clamping the workpiece 4. The lower part of the jaw 2 is provided with a key 8, which slides with the corresponding guide groove 7. Cooperate; the lower end of the guide block 6 is provided with a connecting part 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com