Flexible efficient grinding and polishing device

A high-efficiency, grinding-polishing technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of multi-energy, load energy consumption, large load, etc., and achieve stable and soft swing Effect of stopping and starting, prolonging equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

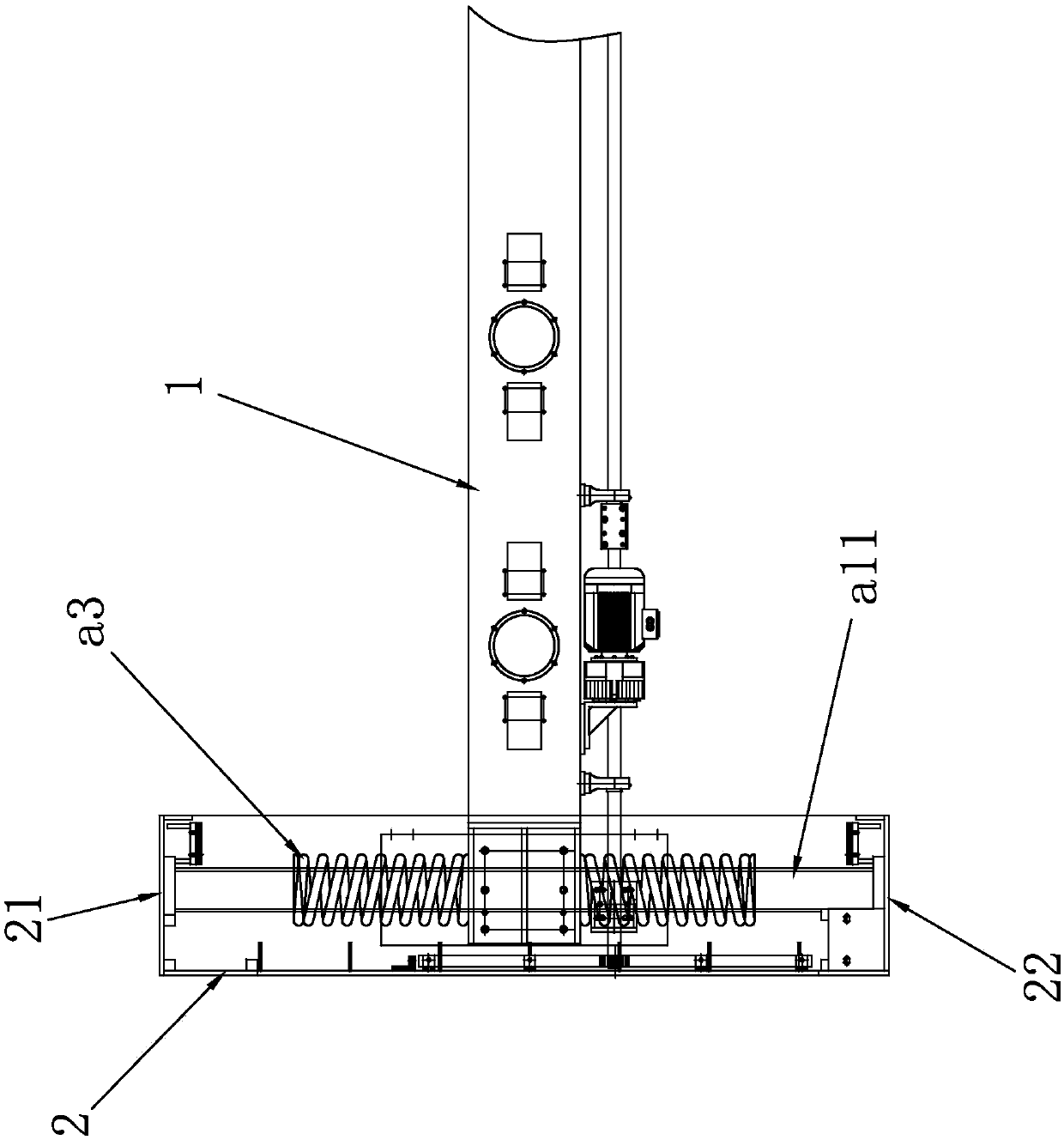

[0013] Embodiment 1, a kind of flexible high-efficiency grinding and polishing equipment, such as figure 1 As shown, the flexible and efficient grinding and polishing equipment includes a frame on which a swing beam 1, a support 2, a power device and an accumulator are arranged, and the support 2 is provided with a reciprocating mechanism perpendicular to the swing beam 1. track, the support 2 also includes a front baffle 21 and a rear baffle 22, the front baffle 21 and the rear baffle 22 are respectively located at the front and rear of the reciprocating track, and the swing beam 1 is provided with a movable connection with the reciprocating track. As for the moving part, the power device drives the swing beam to swing forward and backward along a reciprocating track, and the accumulators are installed in pairs on the front fender 21 and the rear fender 22 respectively, and are connected with the swing beam 1 at the same time. The accumulator is a spring-type accumulator, com...

Embodiment 2

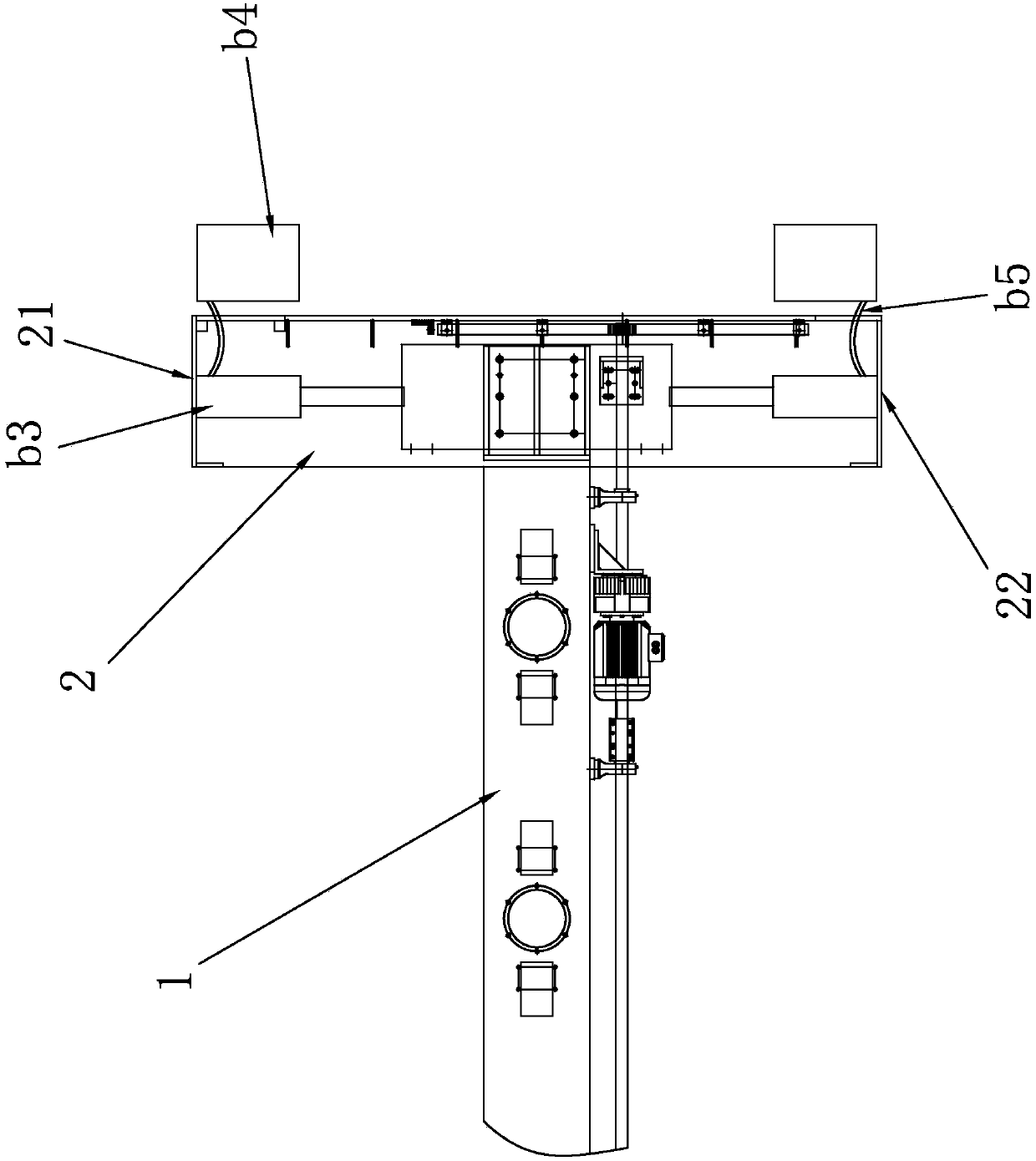

[0014] Example 2, such as figure 2 As shown, the difference between it and Embodiment 1 is that the structure of the accumulator is different, and the accumulator is a gas accumulator, including a hydraulic cylinder b3 and an air bag b4, and the hydraulic cylinder b3 is fixedly installed on the front baffle 21 On the tailgate 22, its piston rod is fixedly connected with the swing beam 1, and the air bag b4 communicates with the hydraulic cylinder b3 through the oil pipe b5. An electromagnetic valve for auxiliary braking is also provided on the oil pipe b5. During the deceleration and braking process of the swing beam 1, the oil in the compression cylinder b3 will be compressed like the air bag b4, and the pressure of the oil in the air bag b4 will increase, consuming the kinetic energy of the swing beam 1; when the swing beam 1 is ready for reverse pneumatic, The pressure in the air bag b4 pushes the swing beam 1 through the compression cylinder b3, and converts the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com