Method for monitoring pressure in device for pneumatically adjusting seat in transportation means

A vehicle and pressure technology, applied in the measurement of hydraulic/pneumatic force, measuring fluid pressure through mechanical components, vehicle seats, etc., can solve the problem of prolonged filling time, and achieve the effect of fast and accurate pressure measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

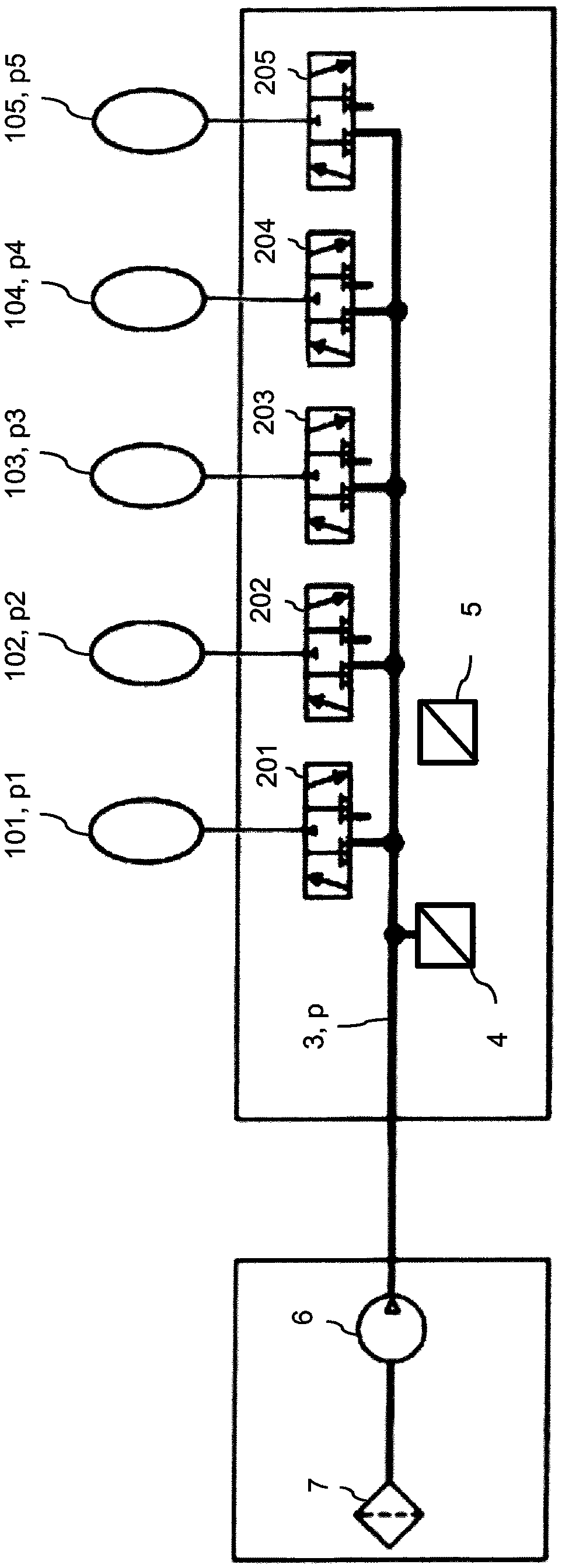

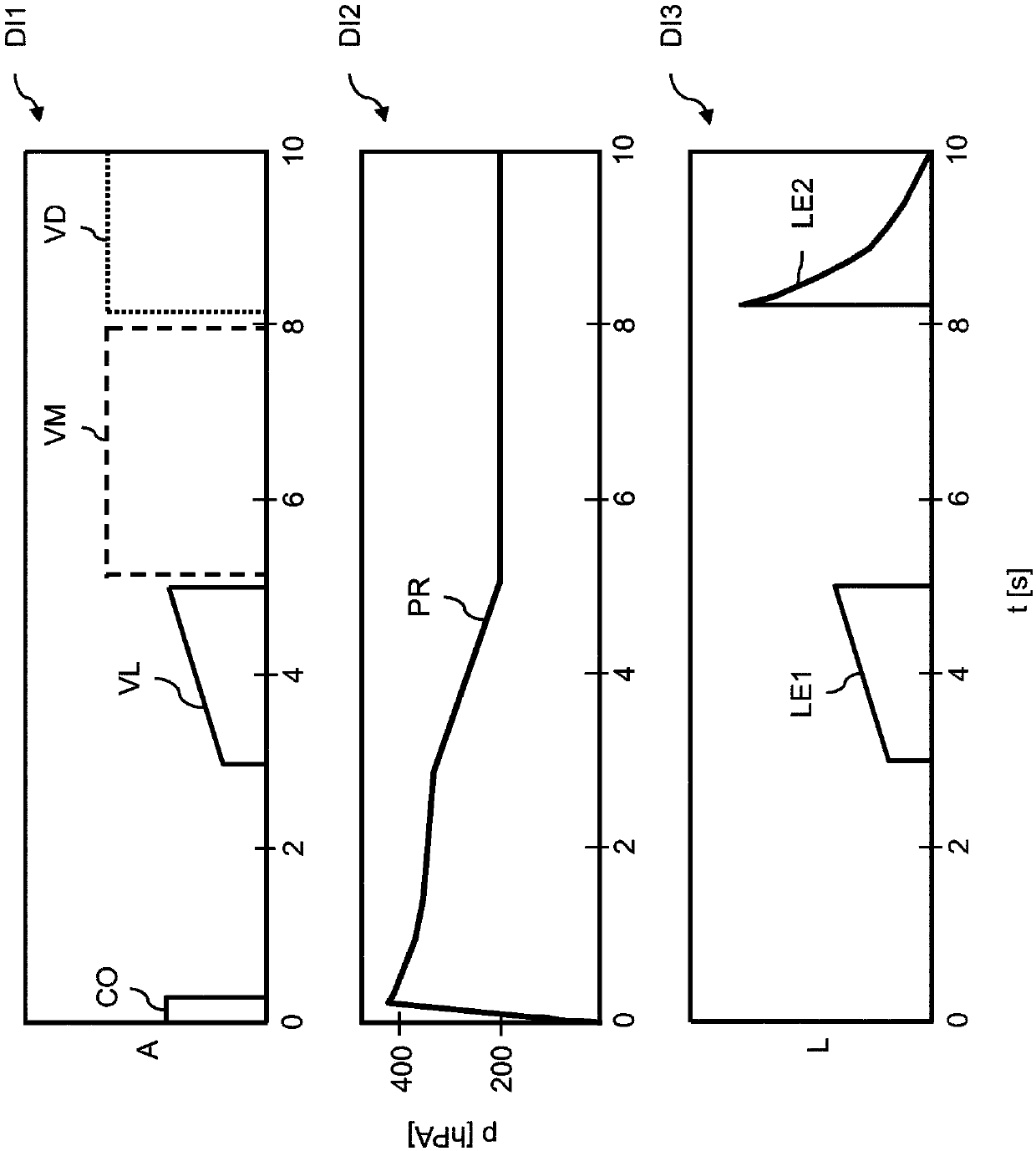

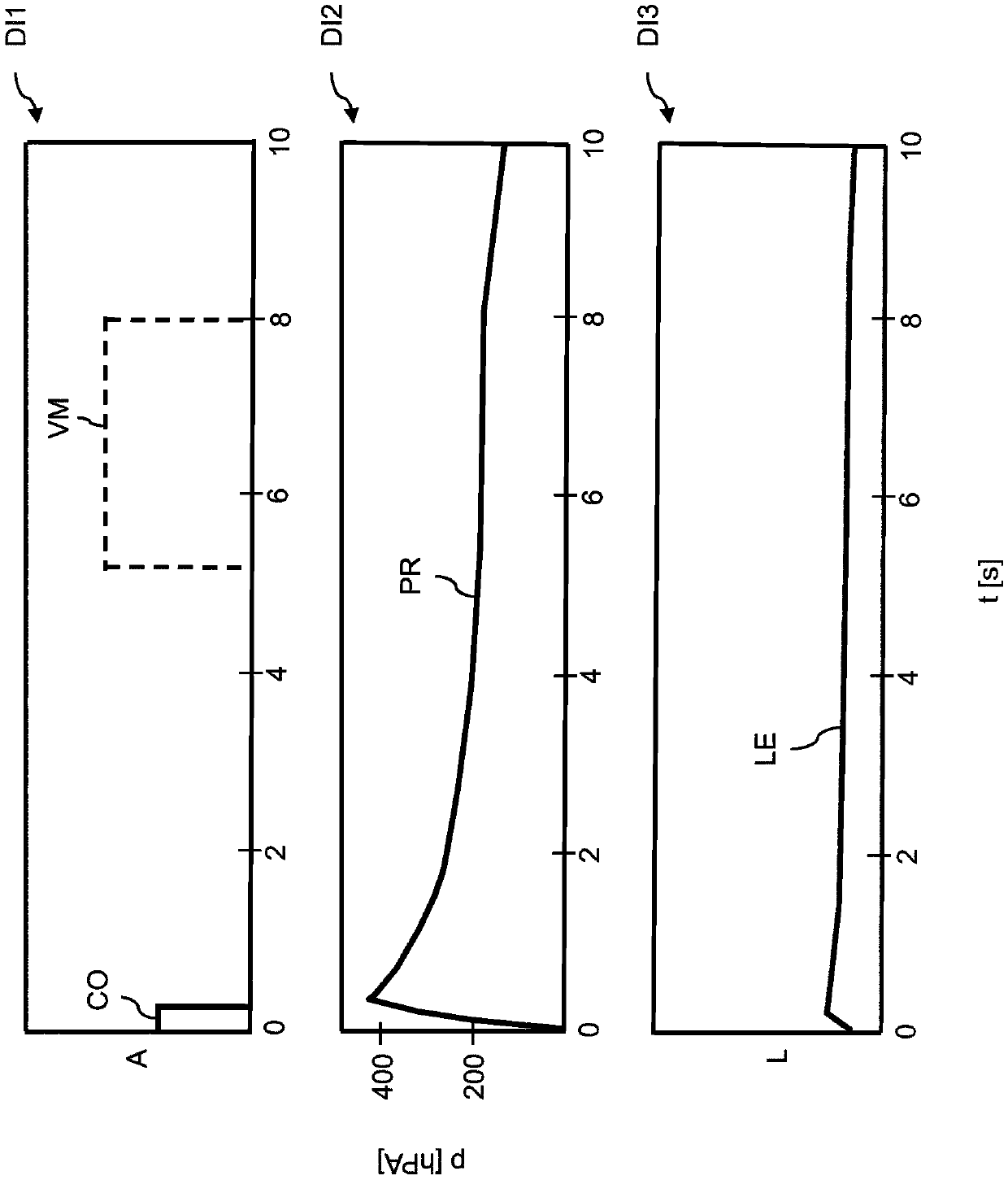

[0028] Below, will be in figure 1 An exemplary embodiment of the method according to the invention is described on the basis of the shown device for pneumatic seat adjustment. The seat adjustment device is integrated in a seat of a motor vehicle and serves, for example, as a lumbar support. The seat adjustment device comprises five air cushions 101 , 102 , 103 , 104 and 105 which are filled with air differently and thus have different volumes and pressures depending on the setting of the seat. For the currently selected seat setting, the corresponding target pressures for the individual pads are stored, specifically target pressure p1 for pad 101 , target pressure p2 for pad 102 , target pressure p3 for pad 103 , target pressure p4 for pad 104 and the target pressure p5 of the pad 105 . The pressure in the individual pads should correspond to these target pressures in order thereby to ensure the selected seat setting.

[0029] Each individual pad is assigned a 3-position 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com