Remnant film recovery device for efficiently cleaning remnant films

A technology of residual film recycling and residual film, which is applied in plant protection covers, botany equipment and methods, gardening, etc., and can solve problems such as affecting efficiency, prone to breakage, and residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

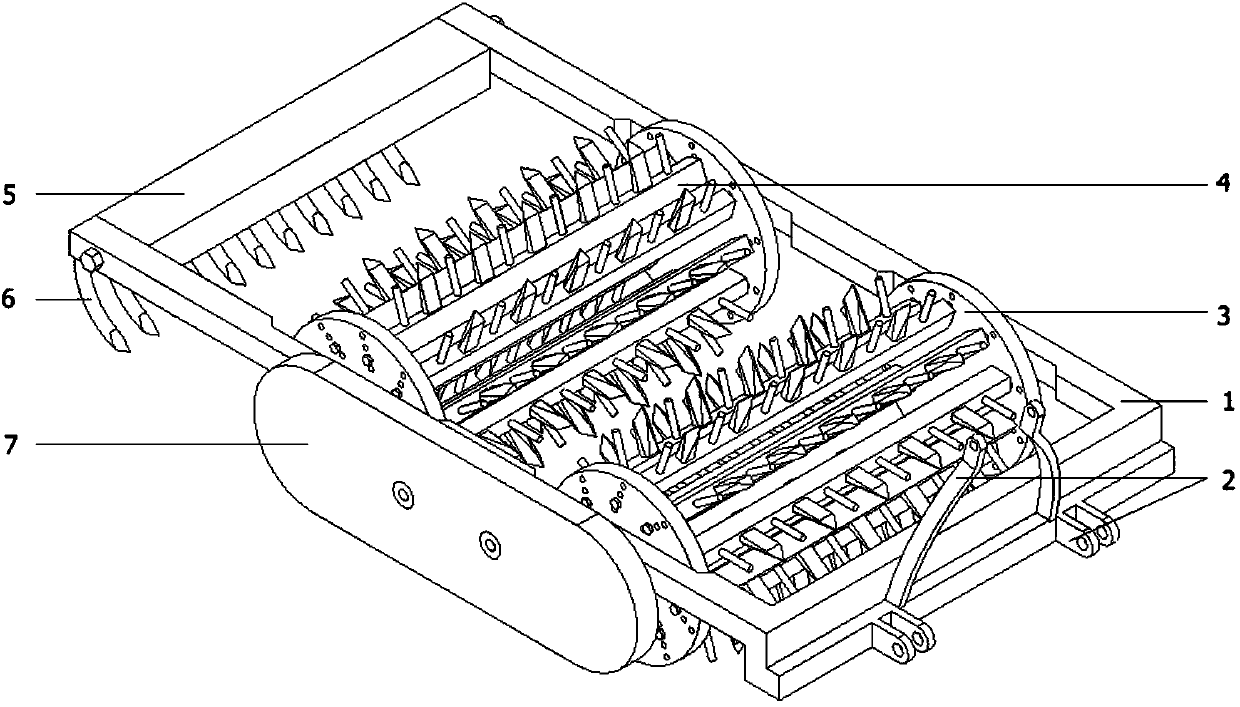

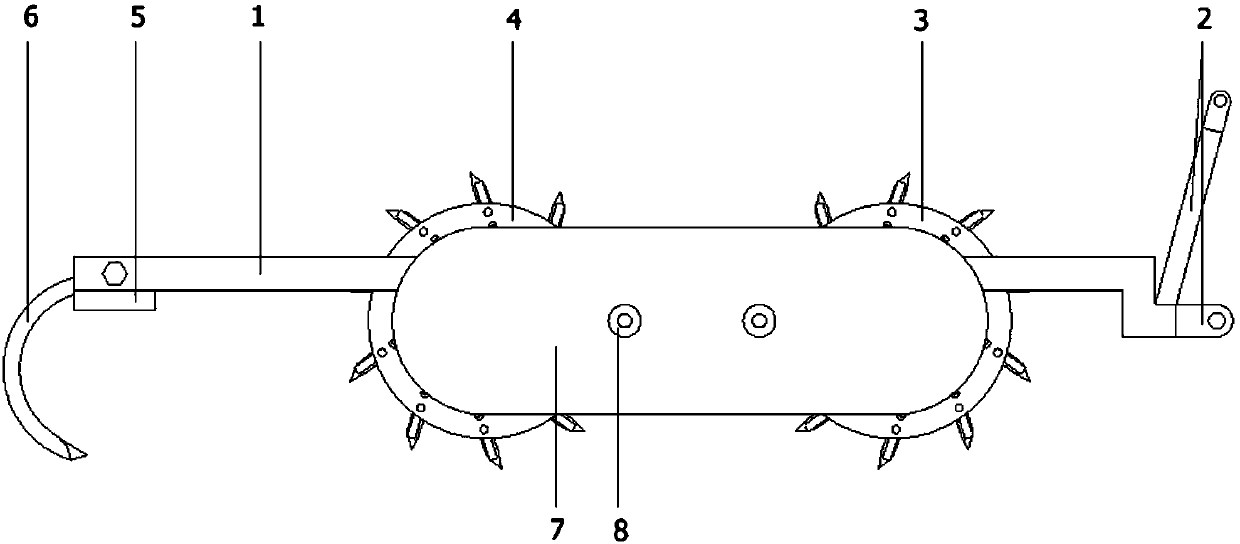

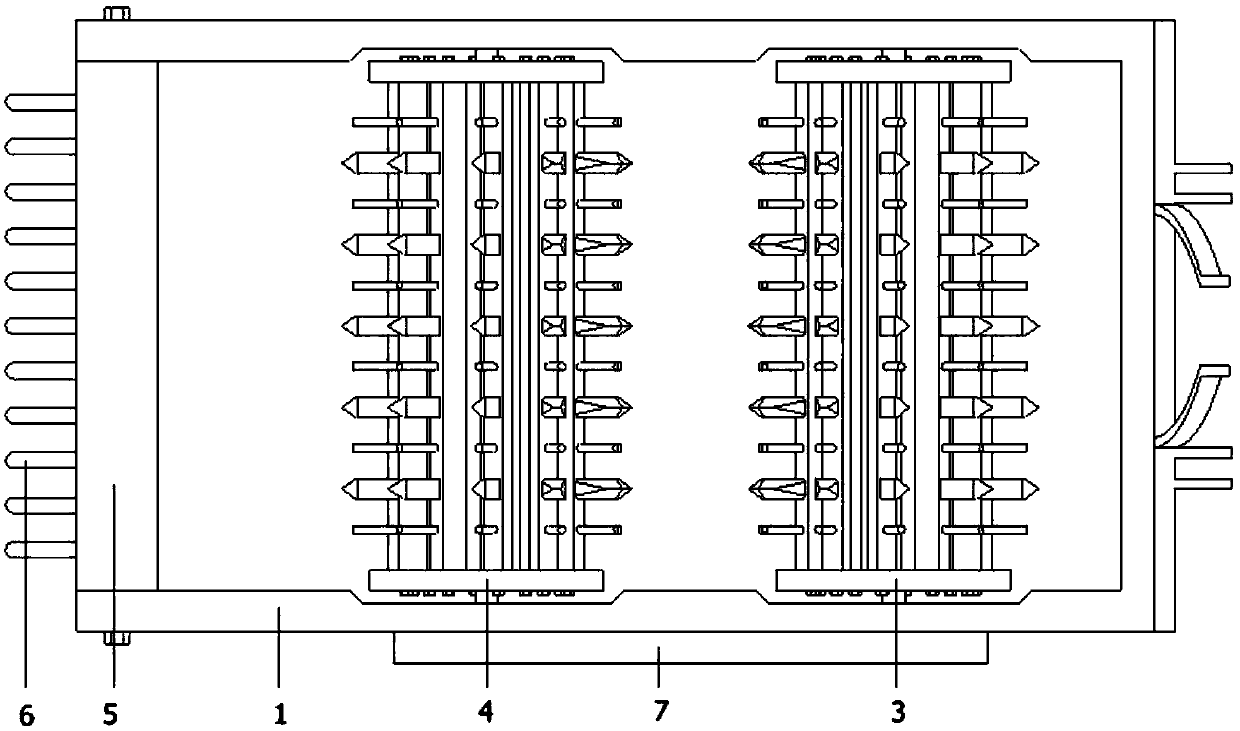

[0026] as attached figure 1 to attach Figure 8 Shown:

[0027]The present invention provides a residual film recovery device for efficiently cleaning residual film, comprising a frame 1, a connecting mechanism 2, a first residual film cleaning roller 3, a second residual film cleaning roller 4, a rectangular block 5, a residual film intercepting hook 6, a protective Cover 7, bearing 8, gear 9, main fixed shaft block 10, auxiliary fixed shaft block 11, disc 12, rotating shaft 13, threaded hole 14, bolt 15, fixed block 16, filming column 17 and filming tooth 18; A connection mechanism 2 is welded on the outer wall of the front end of the frame 1; a rectangular block 5 is fixedly installed on the inner end of the tail end of the frame 1 through a bolt 15, and a plurality of orderly arranged rectangular blocks 5 are welded on the bottom of the rectangular block 5. The residual film interception hook 6; the inner end of the frame 1 is sequentially provided with a first residual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com