Mixing, granulation and size stabilization machine with anti-explosion and anti-combustion functions

A technology of mixing granulating and granulating machine, applied in the field of machinery, can solve the problems of flammable and explosive materials manufacturing granules, high risk, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

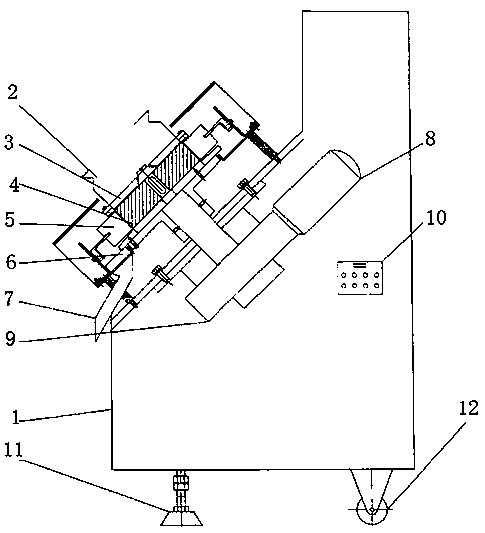

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

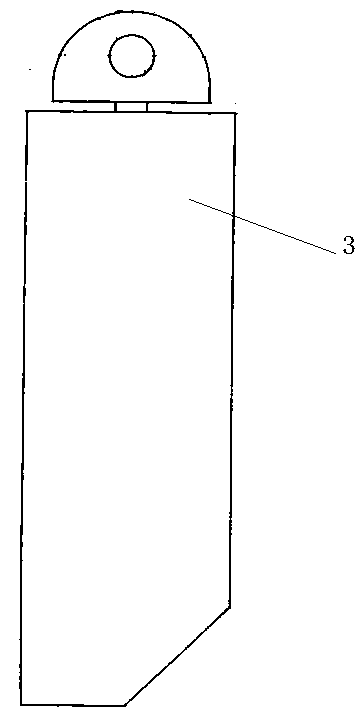

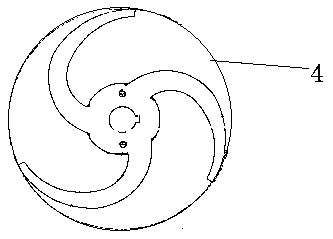

[0023] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a mixing granulation and granulation machine with explosion-proof and flame-proof functions includes a mixing granulation granulation machine. The mixing granulation granulation machine includes a shell 1, and a feed port is provided on the upper part of the shell. A round tubular screen 2 is installed at the mouth, a granulation knife 4 is arranged inside the screen, a cutting knife 5 is installed outside the screen, and a discharge port 7 is provided at the lower part of the shell, and the discharge port is arranged below the screen ; The granulation knife and the screen are driven by a motor 8; a first temperature sensor is provided in the housing, and the first temperature sensor is connected to a signal processing module, and the signal processing module controls and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com