Combined mining rail crossheading circulating forward type forepoling system

A technology of advanced support and track trough, which is applied in the direction of mining equipment, earthwork drilling, mine roof support, etc., to achieve the effect of improving the efficiency of moving frames, ensuring stability and safety, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

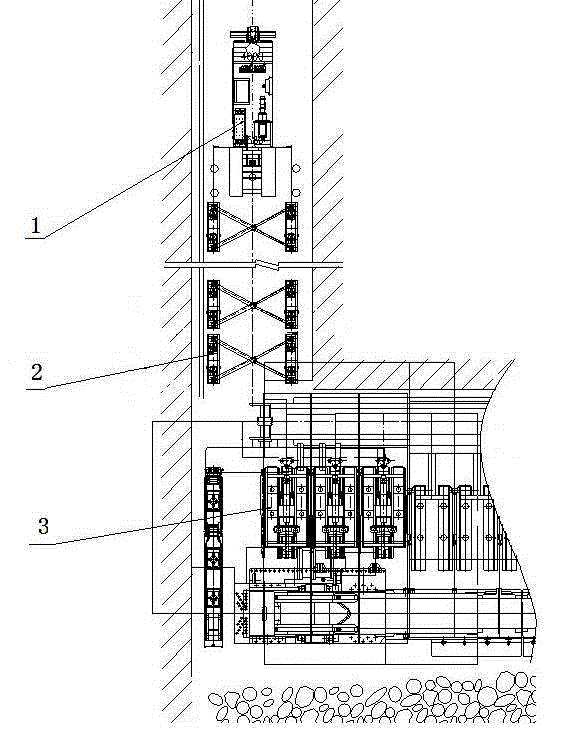

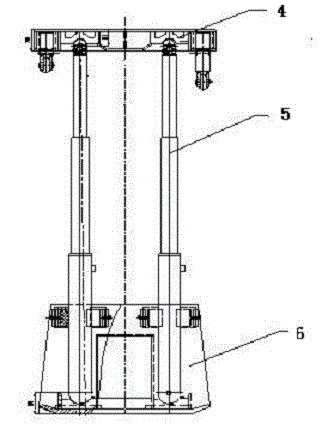

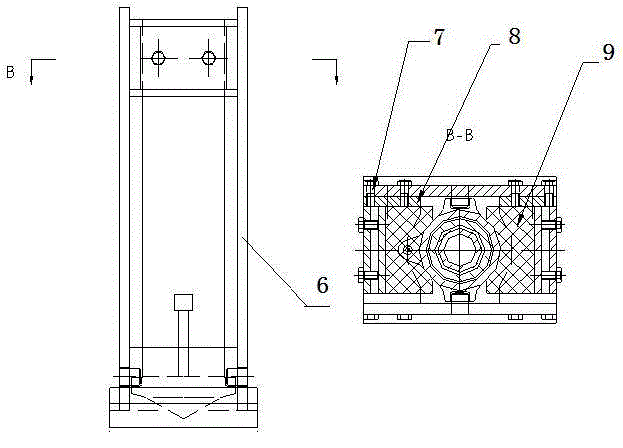

[0024] Specific implementation methods: such as figure 1 As shown, a fully-mechanized track cyclically moving forward advance support system includes an advance support 2 arranged in a coal mine roadway, and a multifunctional handling device 1 for moving the advance support 2 . The present invention adopts a kind of advanced support to be arranged along the roadway to realize the support of the roadway. The distance between the front and back of each two sets of advanced support 2 is 200mm (the distance can be increased according to the support strength), and the distance between the last support 2 and the front edge of the end is 400mm. , a group of end and tail frames are arranged behind the leading support 2 for supporting the end roadway. The center-to-center distance between the left and right sides of each bracket 2 is 780-2580 mm, the inner profile of the bracket 2 is 460-2262 mm, and the outer profile is 1200-3000 mm. like image 3 As shown, the column 5 of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com