Powder room for suction coating in pipelines

A technology of pipe fittings and powder booths, which is applied in the direction of cleaning methods using gas flow, cleaning methods and utensils, and spray booths. It can solve problems such as small inner diameters and difficulties in spraying anti-corrosion coatings, and achieve the effects of anti-corrosion and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

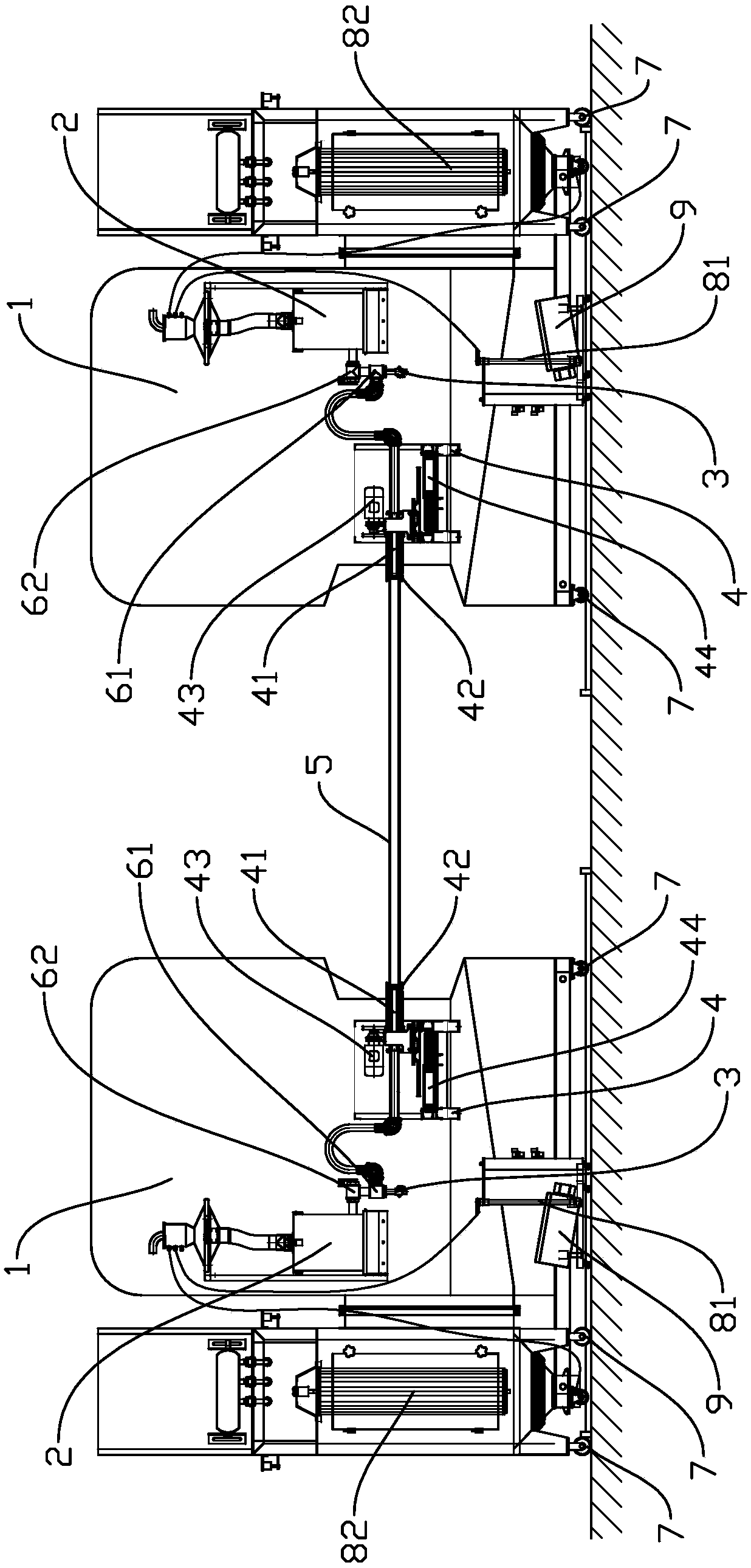

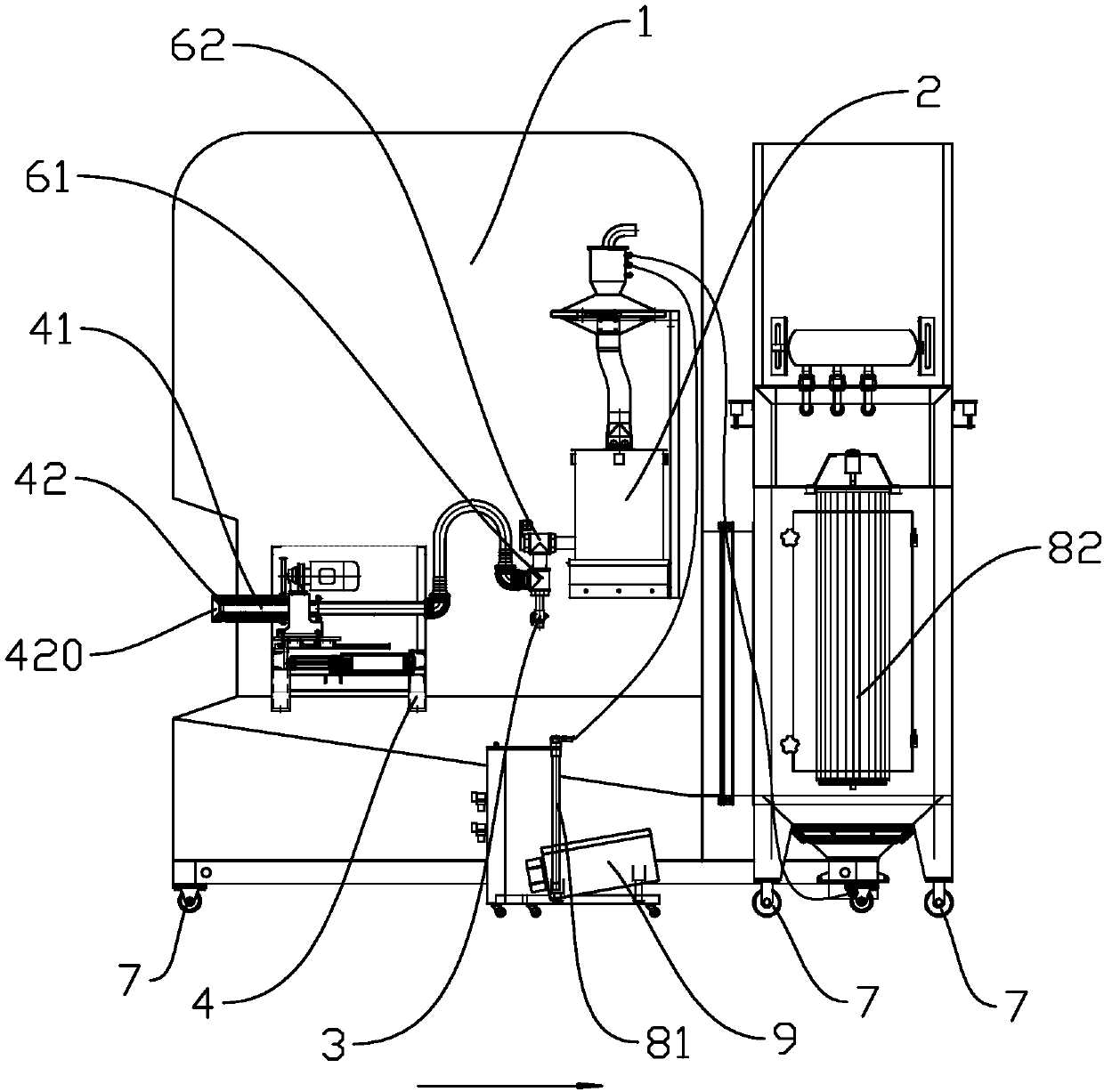

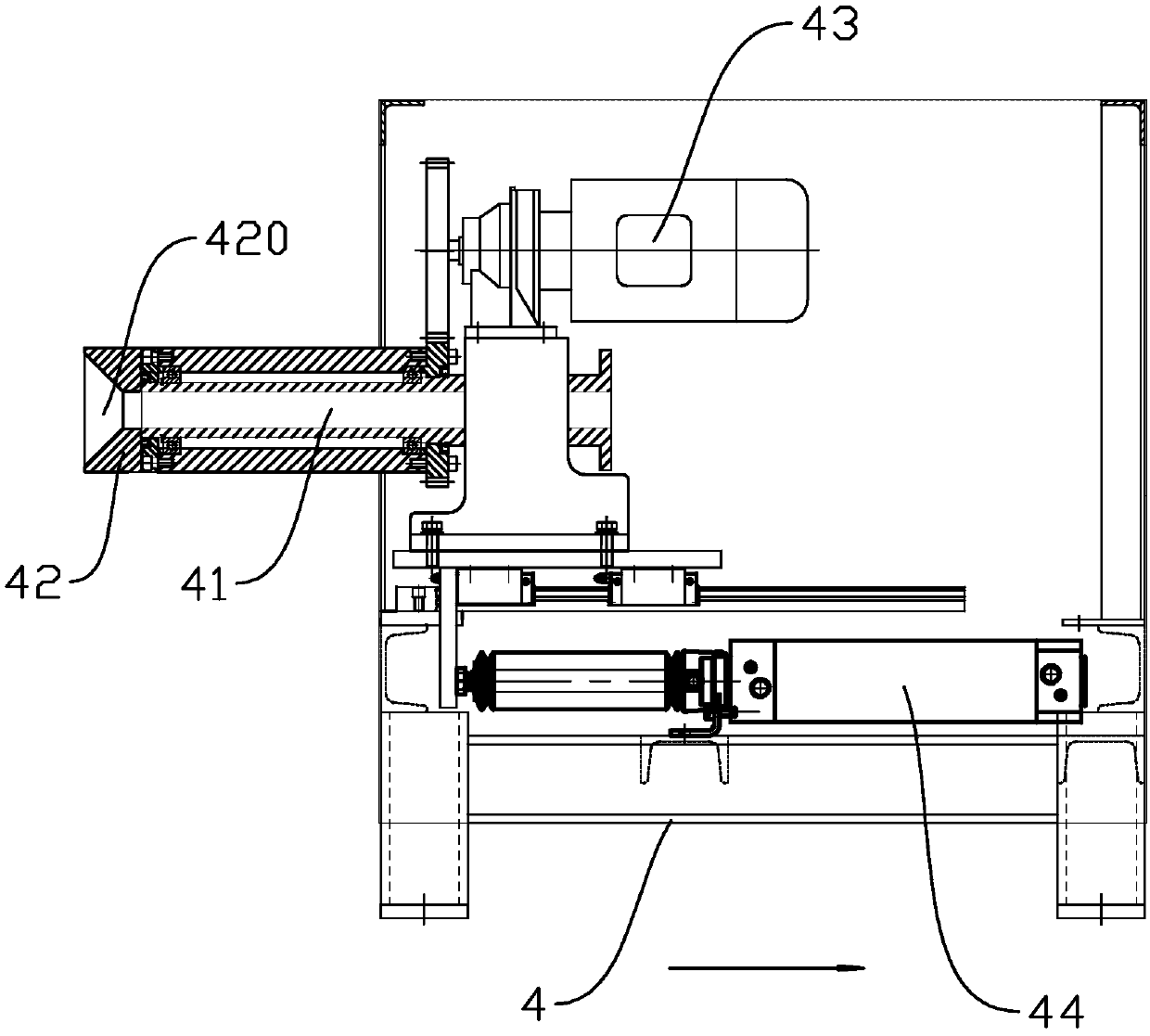

[0025] refer to Figure 1 to Figure 4 ( figure 2 and image 3 The direction indicated by the middle arrow is the front of this article), a powder room for suction coating in pipe fittings, including a room body 1, a powder bucket 2, a vacuum cleaner 3 and a clamping and rotating device 4; the powder bucket 2 is set On the room body 1, it is used to store powdery anti-corrosion paint; the vacuum cleaner 3 is arranged on the room body 1, and the vacuum cleaner 3 can suck out the anti-corrosion paint in the powder bucket 2 connected with it; clamping and rotating The device 4 is arranged on the room body 1, the clamping and rotating device 4 is provided with a first suction coating channel 41, and the clamping and rotating device 4 is also provided with a chuck 42, which is used to clamp one end of the pipe fitting 5 to One end of the first suction coating channel 41 is communicated with the inner hole of the pipe member 5, and the other end of the first suction coating channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com