A tea fermentation silo cleaning device

A cleaning device and a technology for tea fermentation, which are applied to cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of no heating block, no oil cylinder, and inability to adjust the height, etc. Labor consumption, scientific and reasonable structure, and the effect of improving cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

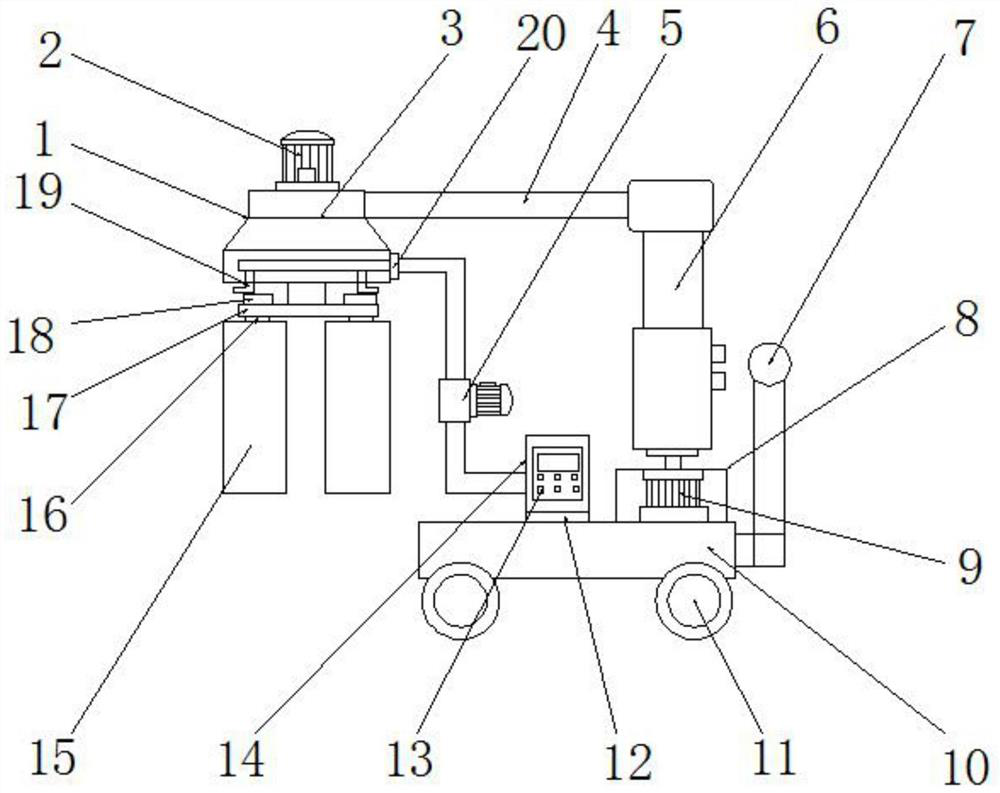

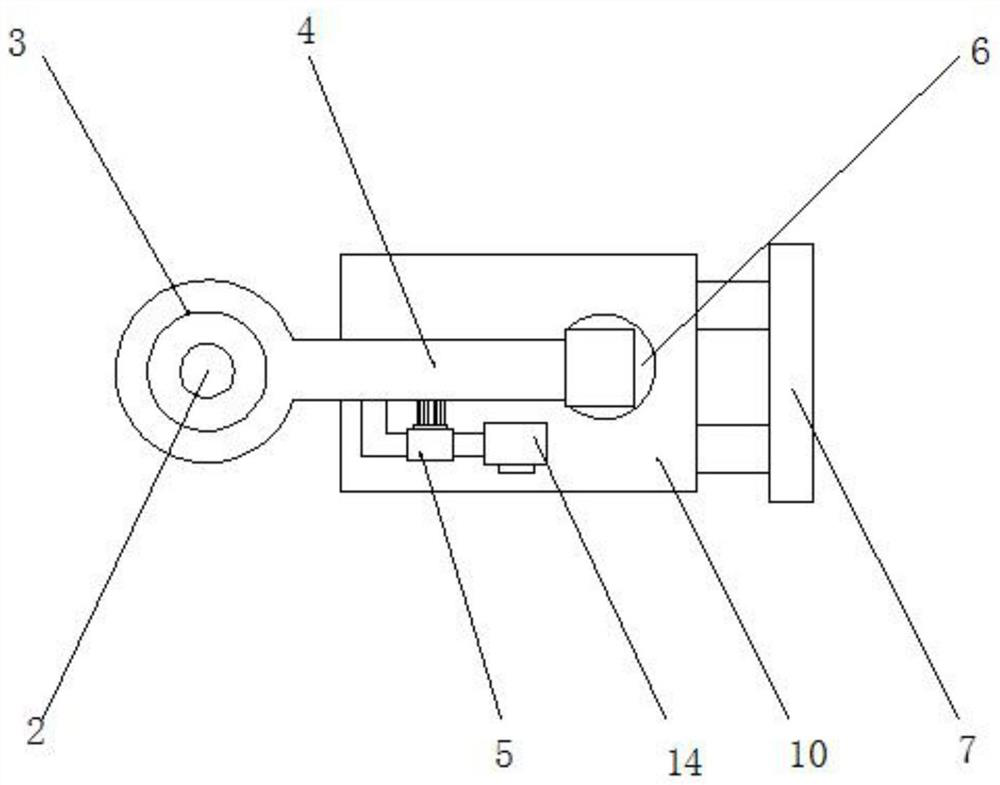

[0017] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a tea fermentation silo cleaning device, including a cleaning device body 1, a motor 2, a cleaning head 3, a connecting rod 4, a pump 5, an oil cylinder 6, a moving handle 7, and a motor layer 8 , servo motor 9, base 10, moving wheel 11, heating block 12, control switch 13, water tank 14, cleaning roller 15, roller 16, turntable 17, cleaning liquid bottle 18, water spray pipe 19 and water inlet 20, cleaning device The outside of the body 1 is provided with a motor 2, one side of the motor 2 is provided with a cleaning head 3, one side of the cleaning head 3 is fixed with a connecting rod 4, the bottom of the cleaning head 3 is connected with a water spray pipe 19, and the bottom of the cleaning head 3 A turntable 17 is provided, a roller 16 is connected to the bottom of the turntable 17, and a cleaning liquid bottle 18 is installed above the turntable 17 corresponding to the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com