Round rod end part automatic hole drilling device

A drilling device and automatic technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of increasing labor intensity of workers, time-consuming and laborious, etc., to avoid labor intensity and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

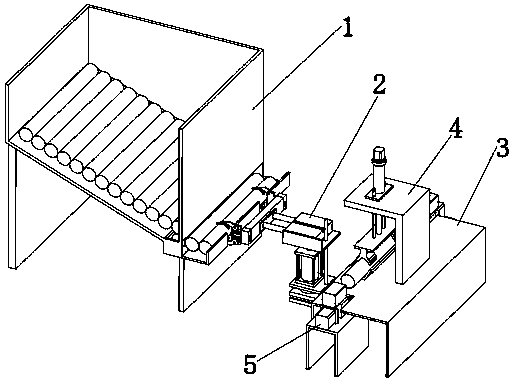

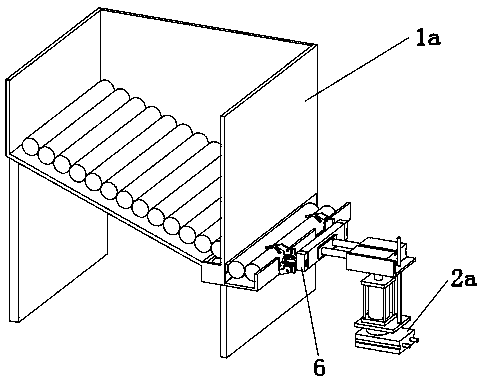

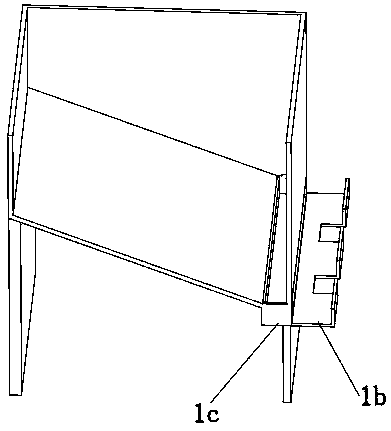

[0026] refer to Figure 1 to Figure 8 The shown automatic drilling device for the end of a round bar includes a storage assembly 1, a material transfer assembly 2, a supporting plate 3, a limit assembly 4, and a drilling hole for drilling the end of the workpiece Component 5, the material shifting component 2 is located between the storage component 1 and the drilling component 5, the limit component 4 is located on the top of the supporting plate 3, the supporting plate 3 is a cuboid structure and the bottom of the supporting plate 3 There are two first support plates for supporting the support plate 3, the drilling assembly 5 includes a first processing assembly 5a and a second processing assembly 5b respectively located on both sides of the limit assembly 4, the first processing assembly 5a has the same structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com