Full-lubricated lifting nut

A lifting screw and screw nut technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of machine tool accuracy, large vibration and noise, wear and tear of lifting screw, and achieve uniform load , Eliminate vibration and noise, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

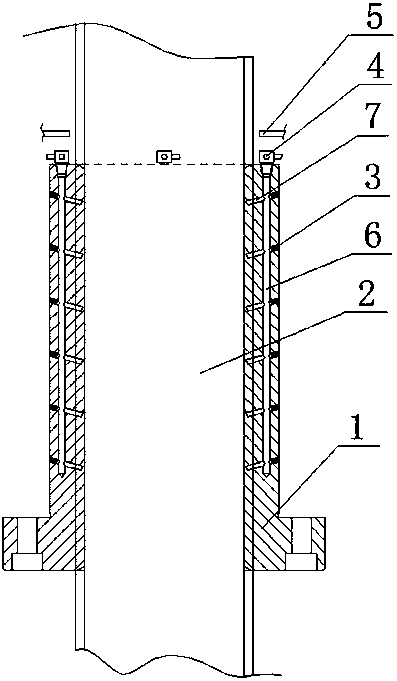

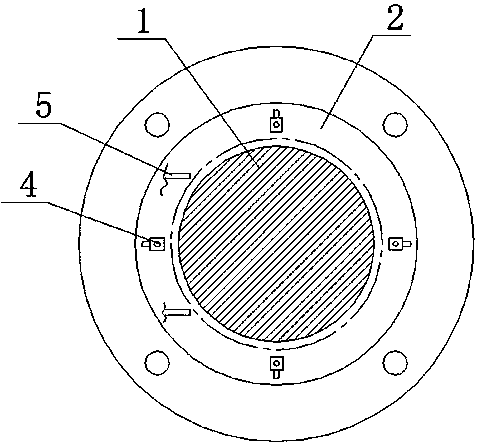

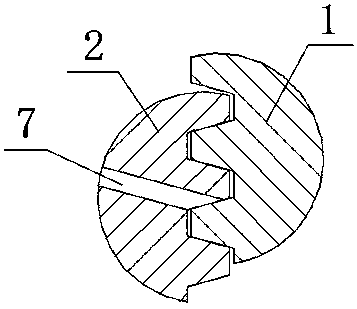

[0012] Such as Figure 1-3 As shown, a fully lubricated lifting nut includes a lifting nut 1, an oil plug 3, a lubricating pipe joint 4 and a lubricating pipe 5, the lifting screw 2 is threaded into the lifting nut 1, and the lifting nut 1 is provided with There is a pair of lubricating pipes 5 for watering the lifting screw 2, and four equiangular annular arrays of long oil holes 6 are drilled on the upper surface of the lifting screw nut 1, and the length of the long oil holes 6 is four-fifths of the length of the lifting screw nut 1 On the side wall of the lifting nut 1, a row of six equally spaced oblique oil holes 7 are drilled outside each long oil hole 6, and the oblique oil holes 7 all pass through the long oil hole 6 rear end on one side and stretch out to On the meshing surface of the lifting nut 1 and the lifting screw 2, the outer ends of the inclined oil holes 7 are provided with oil plugs 3, and the tops of the long oil holes 6 on the lifting nut 1 are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com