Lifting tilt discharging vehicle

A technology for unloading trucks and car bodies, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc. It can solve the problems of unfavorable efficiency, inability to tilt the plane, laborious and other problems, and achieve easy maintenance and maintenance, good support and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

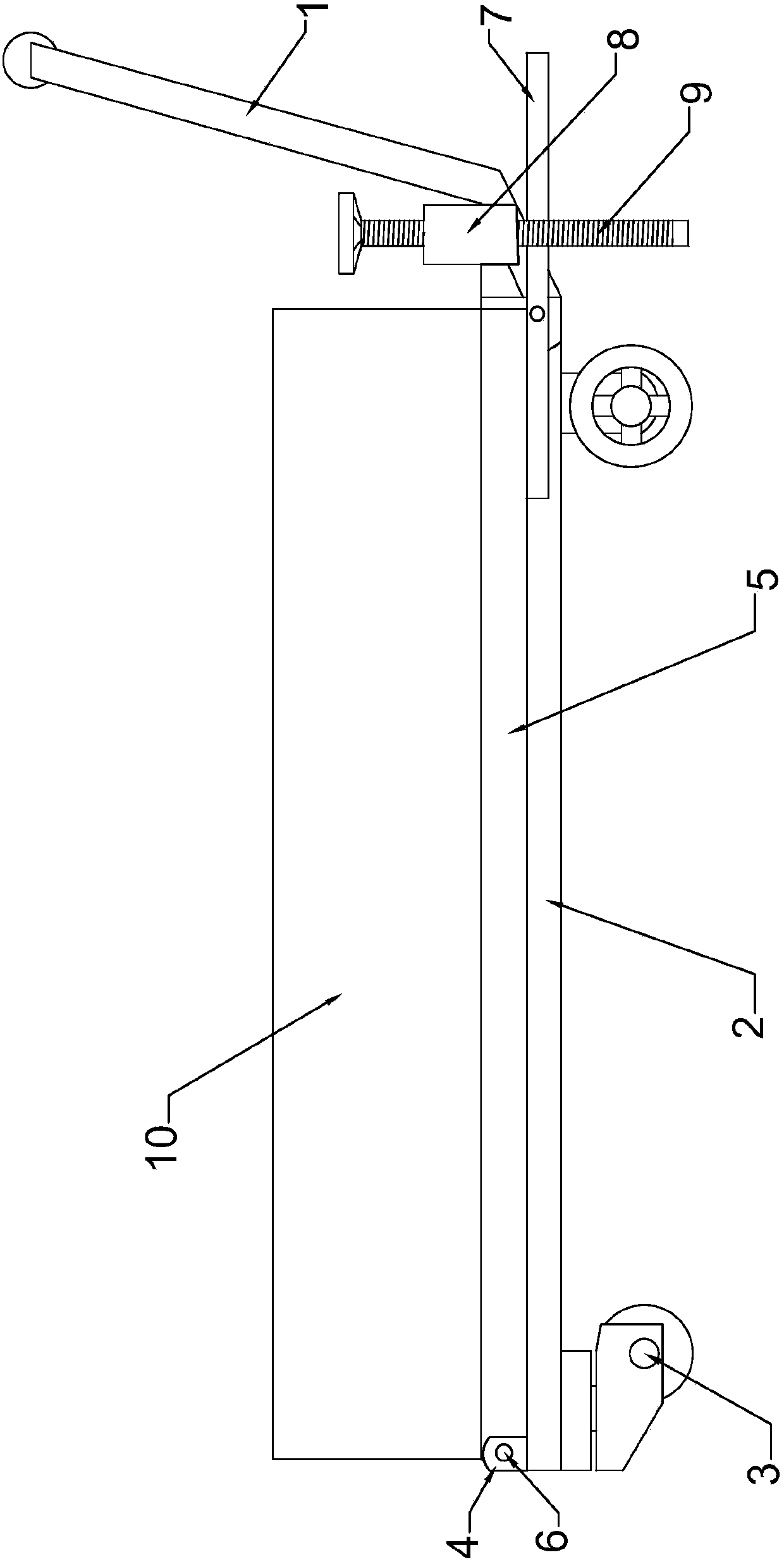

[0011] Such as figure 1 As shown, the lifting and tilting dump truck includes a car body 2 with a handrail 1 at the rear end and a wheel 3 supported by the bottom of the car body 2. The front wheel 3 is a steering wheel, and the front end of the car body 2 surface is fixed with a support plate 4, which rotates One end of the plate 5 is respectively fixed with a rotating shaft 6 inserted in the two supporting plates 4, and the other end of the rotating plate 4 is provided with a rotatable pedal 7 inside the car body 2, and the inner end of the pedal 7 is located below the rotating plate 4 , the other end of stepping on the pedal 7 is located below the handrail 1, and the two sides of the lower end of the handrail 1 are respectively fixed with supporting threaded sleeves 8, and each supporting threaded sleeve 8 is respectively screwed with a supporting threaded column 9, and the surface of the rotating plate 4 is provided with A storage box 10 with an opening is left on the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com