Cold storage defrosting control system and control method

A control system and control method technology, which is applied in defrosting, refrigerators, refrigeration components, etc., can solve the problems of reducing refrigeration cycle efficiency, increasing energy consumption, and no cooling, and achieves the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

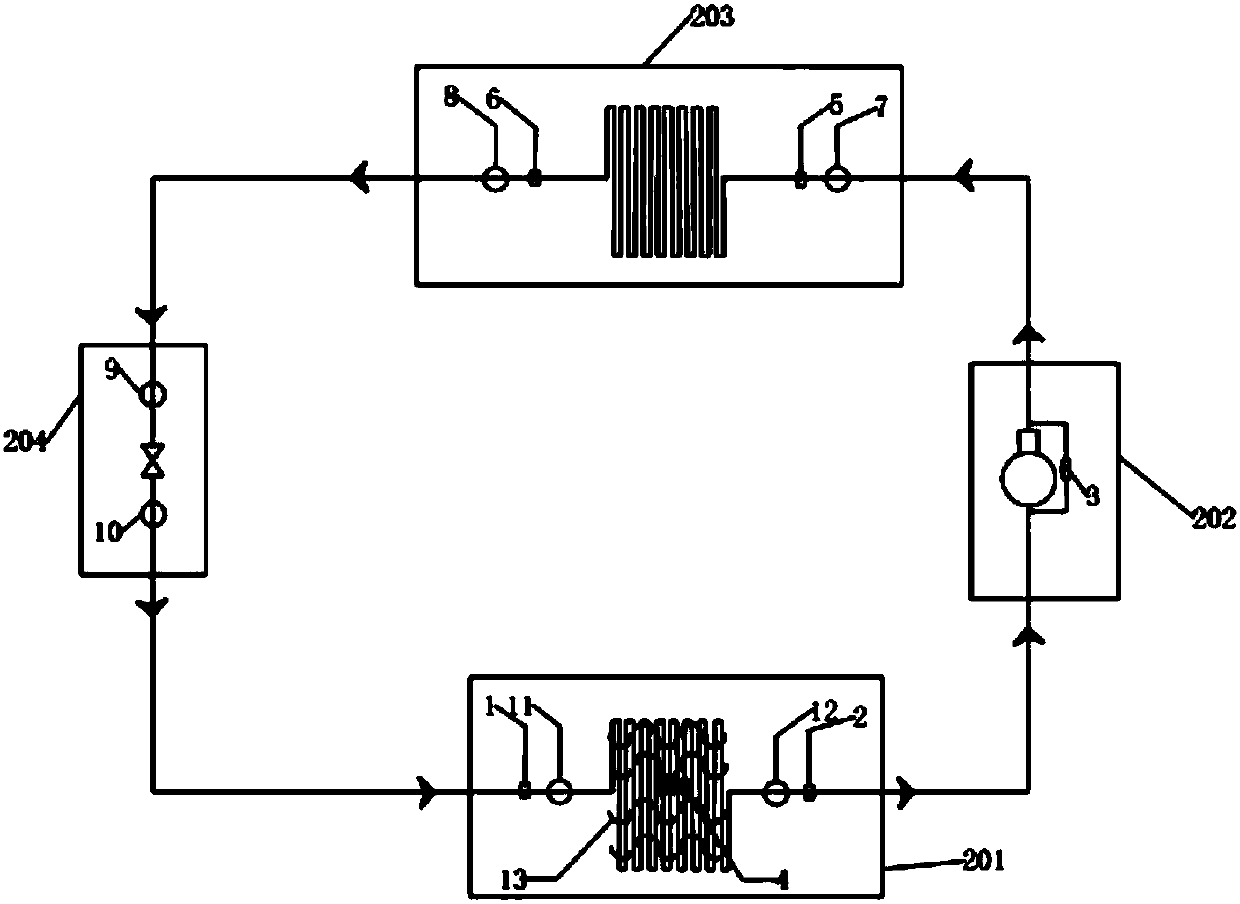

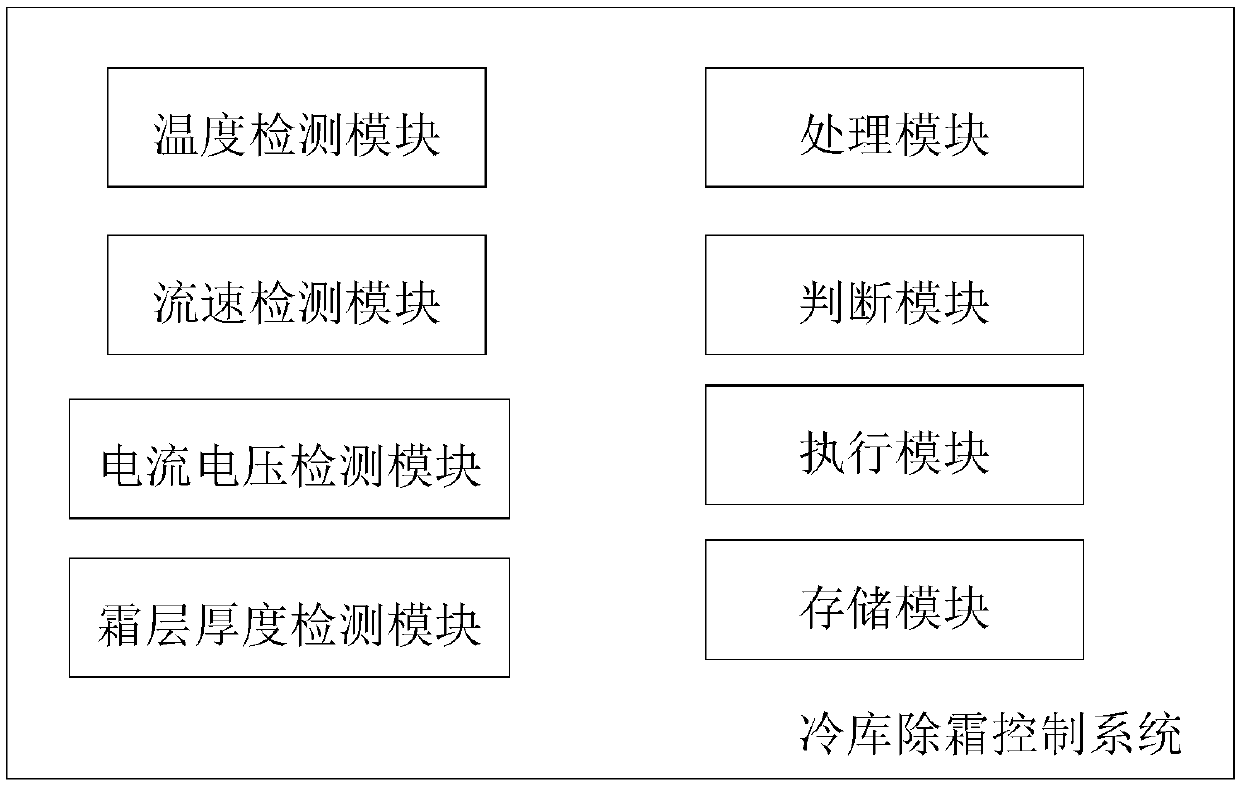

[0057] like figure 1 , 2 As shown, the cold storage system of the present invention includes an indoor evaporator 201, a compressor 202, an outdoor condenser 203, a throttling device 204 and connecting pipes; the cold storage defrosting control system includes a temperature detection module, a flow rate detection module, a voltage and current A detection module, a processing module, a judgment module and an execution module.

[0058] Wherein, the temperature detection module is used to detect the inlet and outlet temperatures of the indoor evaporator 201 and the outdoor condenser 203. Type thermocouple 2; And be located at the embedded thermocouple 5 of the inlet of outdoor condenser 203 and the embedded thermocouple 6 of outlet;

[0059] The flow velocity detection module is used to detect the flow velocity of the indoor evaporator 201, the outdoor condenser 203, the throttling device 204 and the connecting pipes. In this embodiment, the flow velocity detection module is re...

Embodiment 2

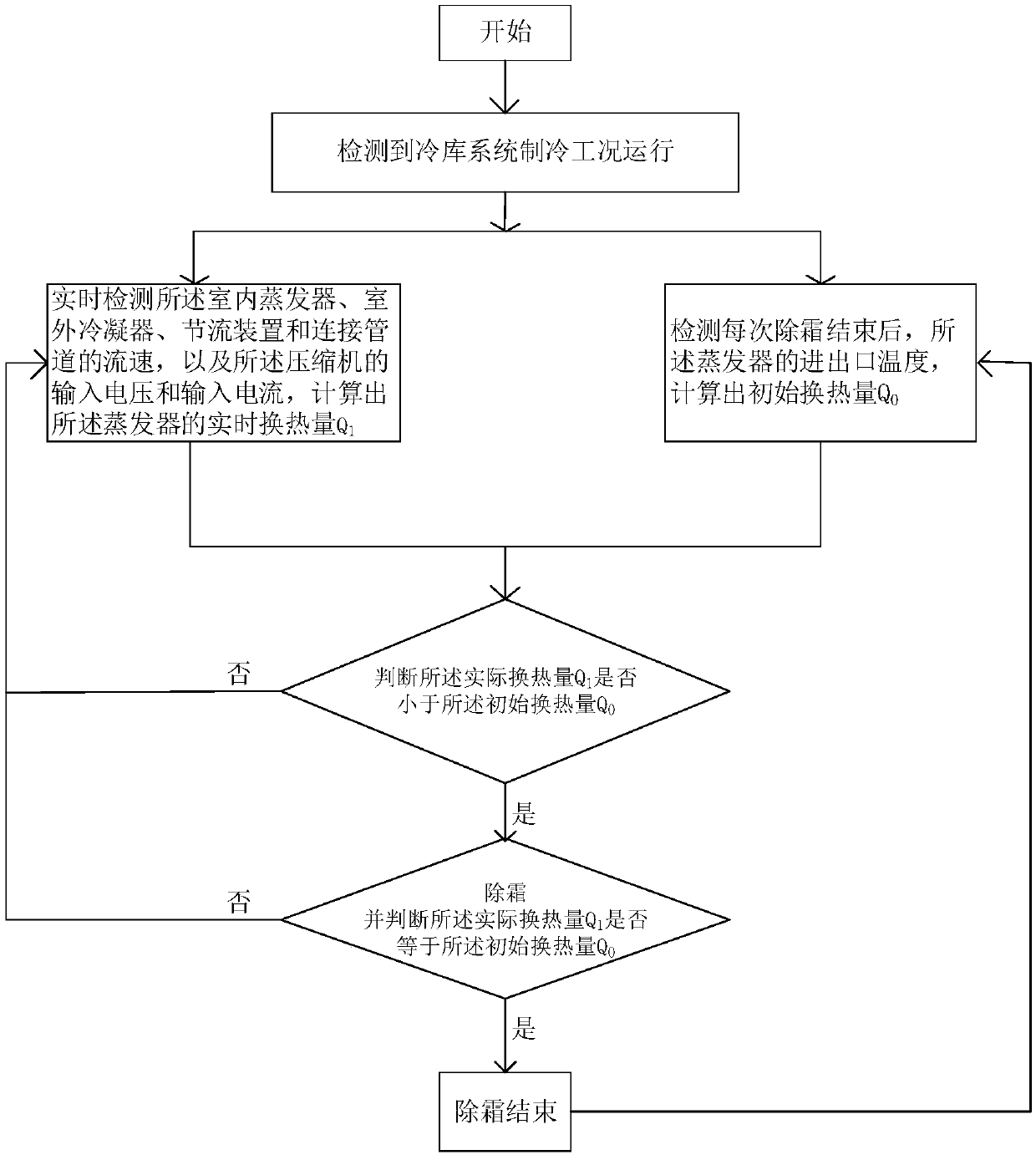

[0080] This embodiment proposes a cold storage defrosting control method, such as image 3 As shown, the steps are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com