Temperature prediction method of IGBT module with NTC thermistor

A technology of thermistor and prediction method, which is applied in the direction of thermometers, thermometers, measuring devices, etc., which use electrical/magnetic components directly sensitive to heat, can solve the over-temperature protection deviation of IGBT modules and affect the normal operation and temperature of IGBT module equipment. Detecting issues such as lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

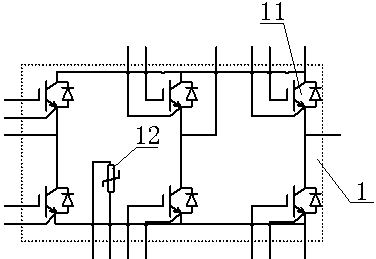

[0018] Example figure 1 Shown, the temperature prediction method of the IGBT module of band NTC thermistor of the present invention comprises the steps:

[0019] Step 1. Detect the current operating current I of the IGBT module 1 through the current sensor, the unit is ampere (A);

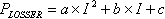

[0020] Step 2. Calculate the current loss of IGBT module 1 according to the operating current I through the following formula , in watts (W),

[0021]

[0022] Among them: a, b, c are the coefficients determined by the parameters of the IGBT module, a represents the conduction loss of the internal resistance of the IGBT module, and its value is equal to , b represents the loss caused by the conduction voltage drop of the IGBT module, and its value is equal to , c represents the switching loss of the IGBT module, and its value is equal to ; the current loss computed without any correction The deviation from the measured loss is less than 10%;

[0023] in:

[0024] Calculate the modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com