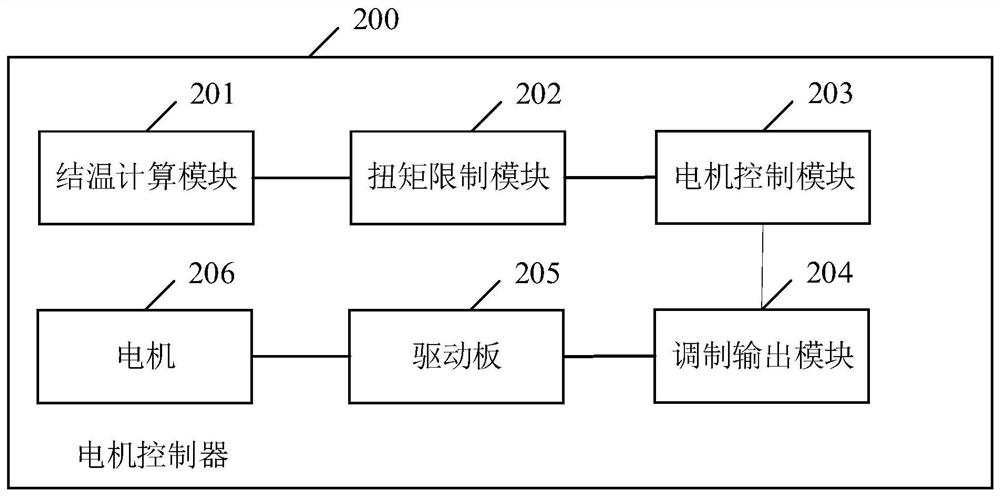

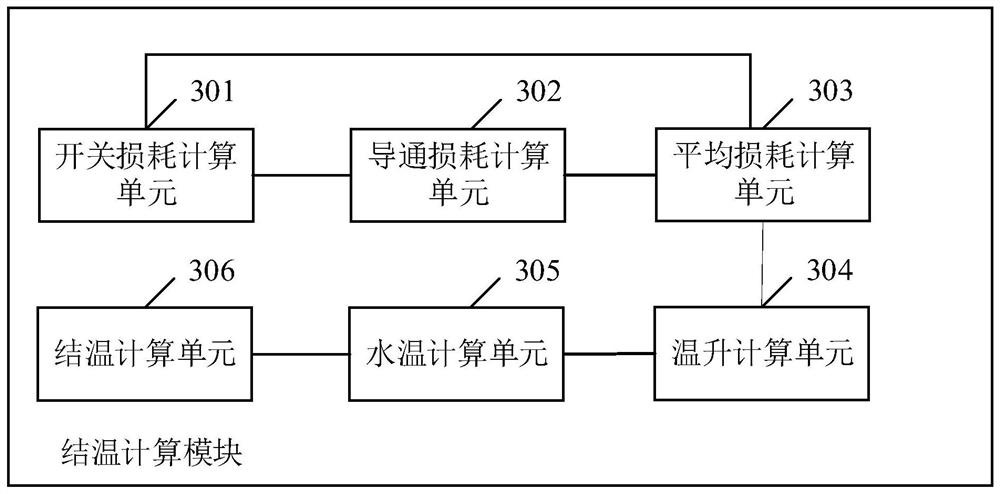

Junction temperature estimation method of power device, power device, motor controller and computer readable storage medium

A technology of power devices and computers, applied in the field of motor controllers, computer-readable storage media, and power devices, can solve the problems of unable to measure the junction temperature of power device MOSFETs and unable to protect power device MOSFETs over temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings.

[0053] Such as figure 1 A schematic diagram showing a possible deployment of a power substrate. The 48V motor controller adopts such as figure 1 In the power substrate shown, there are 12 power device MOSFETs deployed in a "U" shape on the power substrate, which are ZH, ZL, YH, YL, XH, XL, WH, WL, VL, VH, UL as shown in the figure. and UH. One or more temperature sensors may also be disposed on the periphery of each power device, for example, a temperature sensor is disposed between UH and UL as shown.

[0054] In order to prevent over-temperature failure of devices on the power substrate, cooling water is usually introduced to cool down the power substrate. Specifically, the cooling water flows into the water channel below the power substrate from the upper left side of the figure, and flows through the 12 MOSFETs ZH→ZL→YH→Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com